Method for preparing potassium fluoride and coproducing ultrafine white carbon black from ammonium fluorosilicate byproduct in phosphate fertilizer production

A technology of ammonium fluorosilicate and fine white carbon black, which is applied in the directions of alkali metal fluoride, silicon oxide, silicon dioxide, etc., to achieve the effect of extending the product chain, reducing production costs and reducing preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

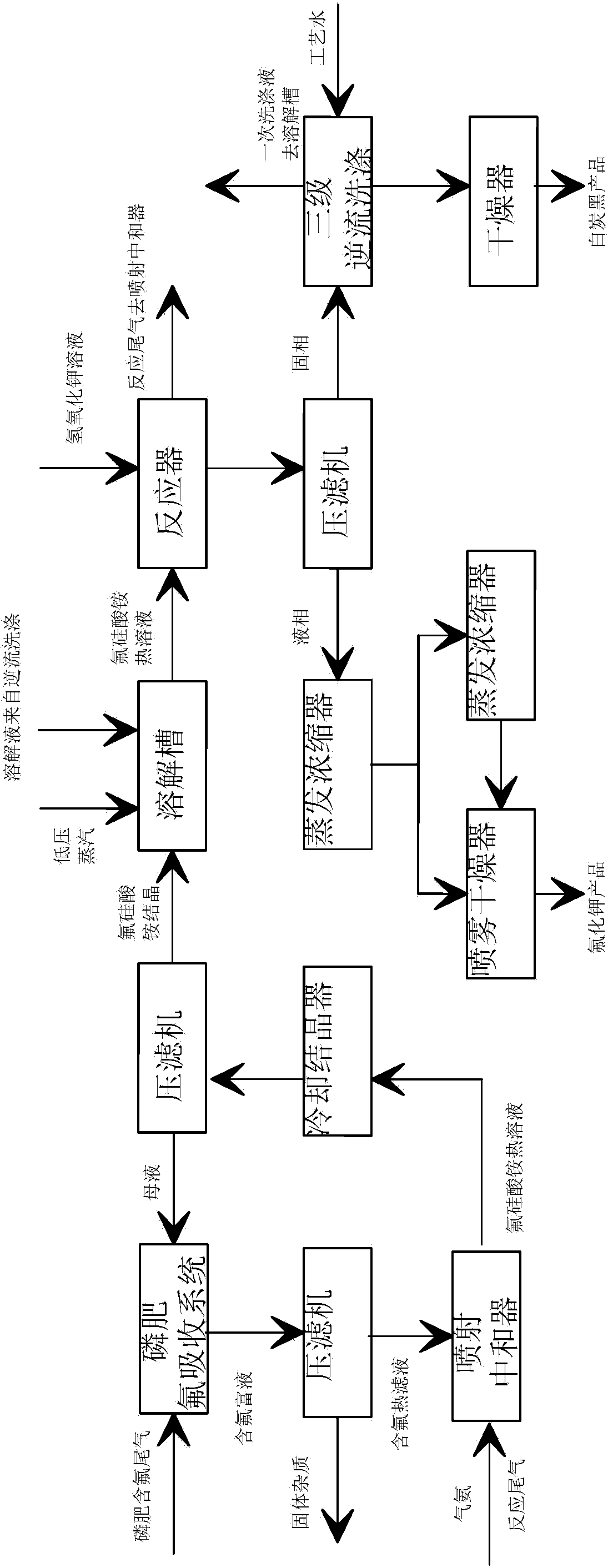

[0024] The preparation of ammonium fluorosilicate adopts the method disclosed in Chinese patent ZL201010200763.2: as figure 1 As shown, the ammonium fluorosilicate crystallization mother liquor is used as the washing liquid in the fluorine absorption system of phosphate fertilizer to absorb fluorine-containing tail gas of phosphate fertilizer to obtain a high-concentration fluorine-containing rich liquid, filter solid impurities through a filter press, and send the liquid phase to the jet for neutralization The device is neutralized with ammonia, crystallized by cooling crystallizer and filtered by filter press to obtain ammonium fluorosilicate crystallization mother liquor and ammonium fluorosilicate solid product, and the ammonium fluorosilicate crystallization mother liquor is returned to the phosphate fertilizer fluorine absorption system.

[0025] It is also possible to follow the conventional ammonia addition neutralization method introduced in the background technology o...

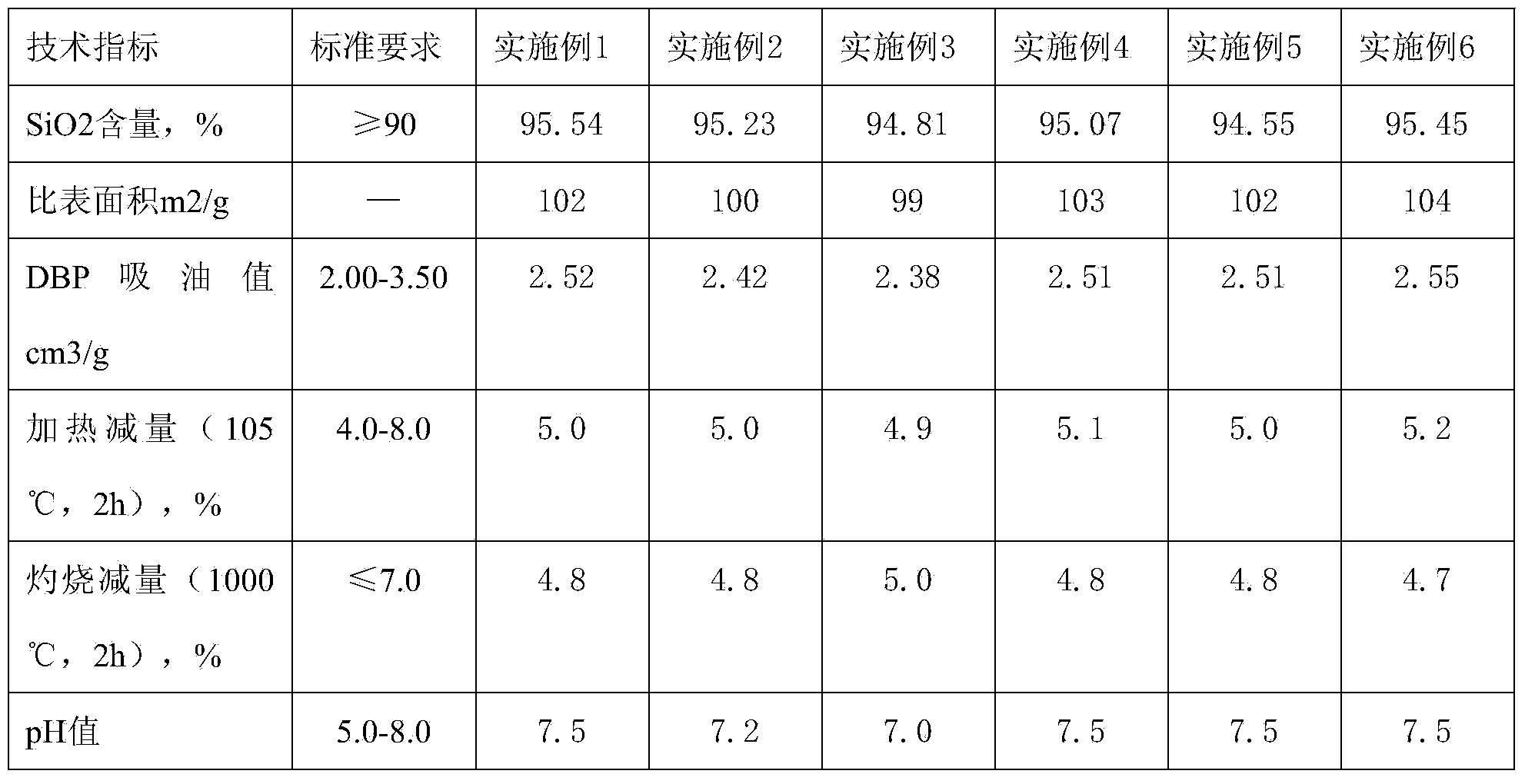

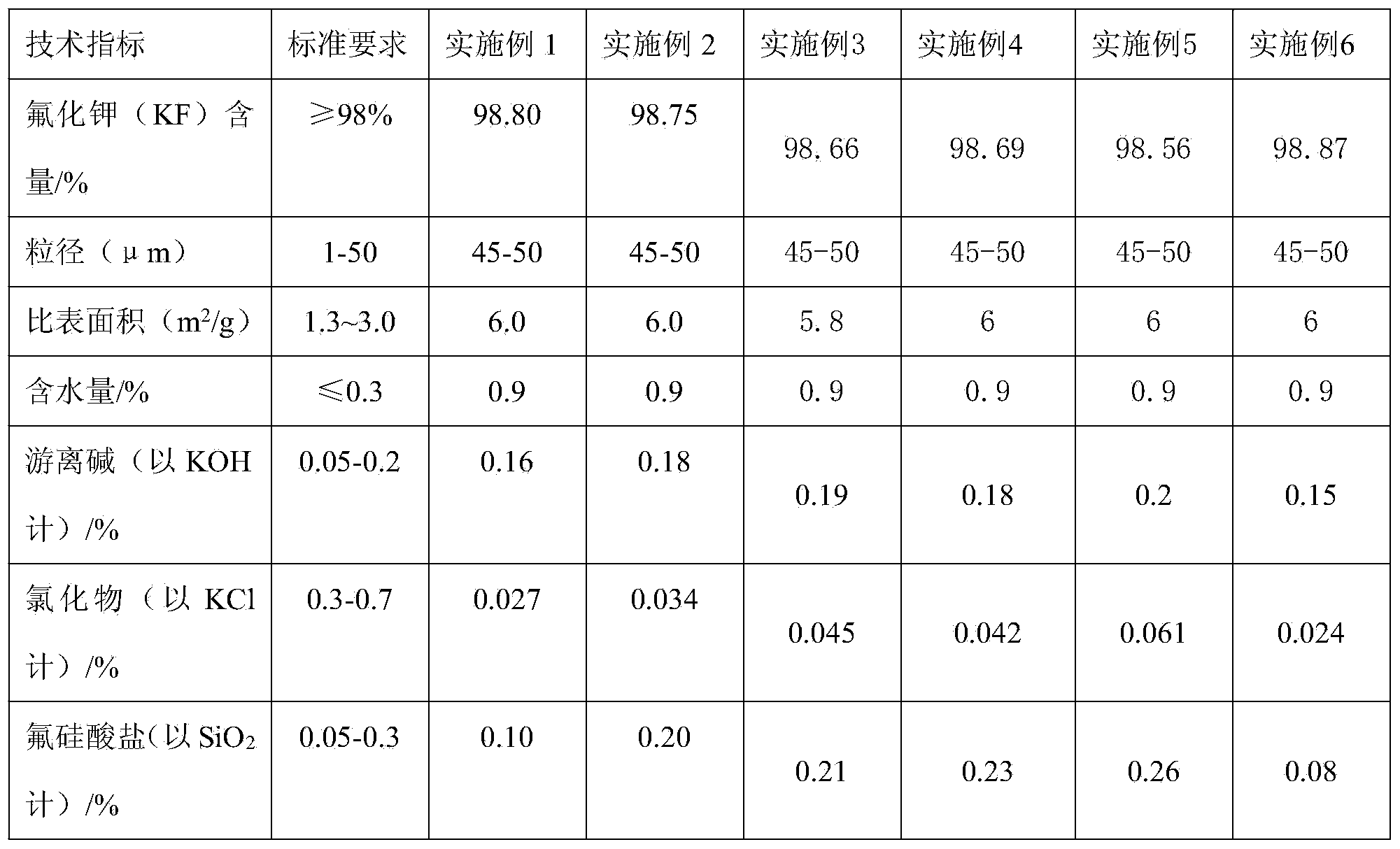

Embodiment 1

[0028] The ammonium fluorosilicate and potassium hydroxide are respectively configured so that the concentration of the ammonium fluorosilicate solution is 20% and the concentration of the potassium hydroxide solution is 35%. Add the ammonium fluorosilicate solution into the reactor, and slowly add the potassium hydroxide solution at a speed of no more than 4ml / min at a temperature of 85°C. KOH / n (NH4)2SiF6 The molar ratio is 6.2:1, stirring, after reacting for 1h, when the pH value of the titration end point is 9.0, stop the reaction, and prepare a slurry containing white carbon black precipitation and potassium fluoride solution, and the reaction tail gas is a mixture of ammonia and water vapor , back as a neutralized raw material for the preparation of ammonium fluorosilicate solid. After the reaction slurry is aged for 0.5h, it is sent to a filter press to filter while it is hot. The solid phase is water-containing white carbon black, and the liquid phase is potassium f...

Embodiment 2

[0030] Method is with embodiment 1. Among them, the concentration of ammonium fluorosilicate solution is 20%, the concentration of potassium hydroxide solution is 35%, the reaction temperature is controlled at 90°C, and the titration end point pH value is 8.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com