Process and device adding aluminium fluoride raw material to aluminium electrolyic tank

An aluminum electrolytic cell and aluminum fluoride technology, which is applied in the field of aluminum fluoride feeding in aluminum electrolytic cells, can solve the problems of high aluminum fluoride loss, reduced product quality, adequate mixing of alumina raw materials, etc., and achieves low aluminum fluoride loss, The effect of improving process performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

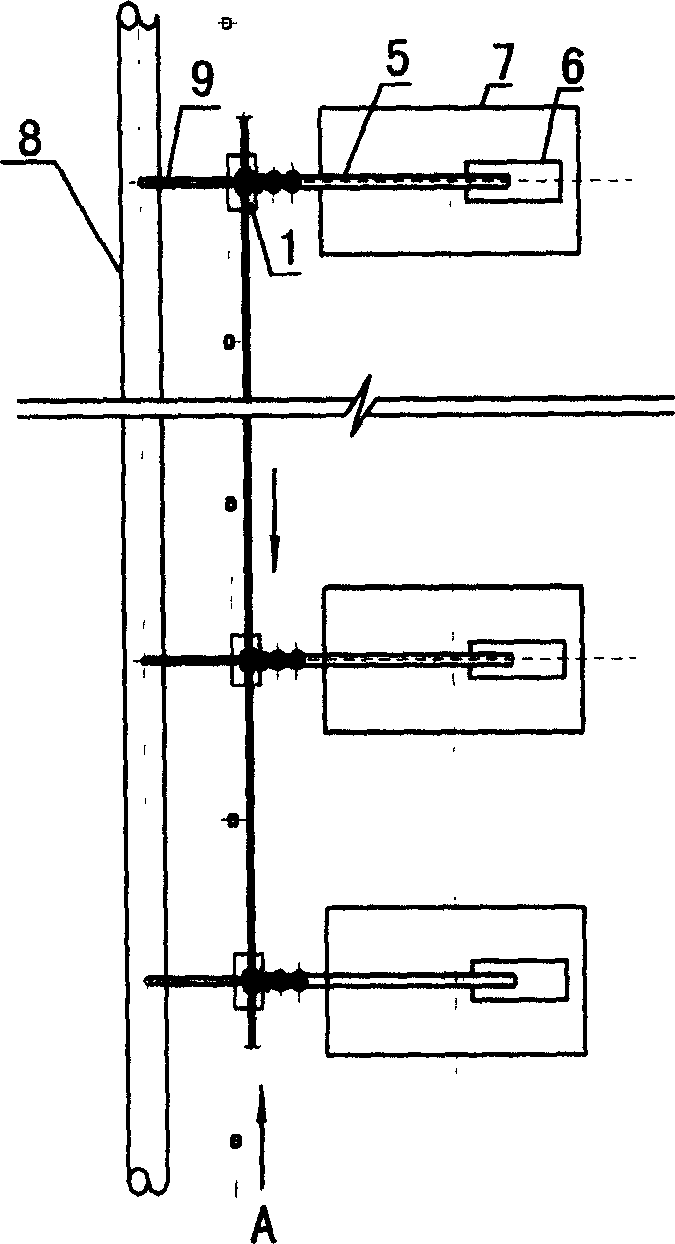

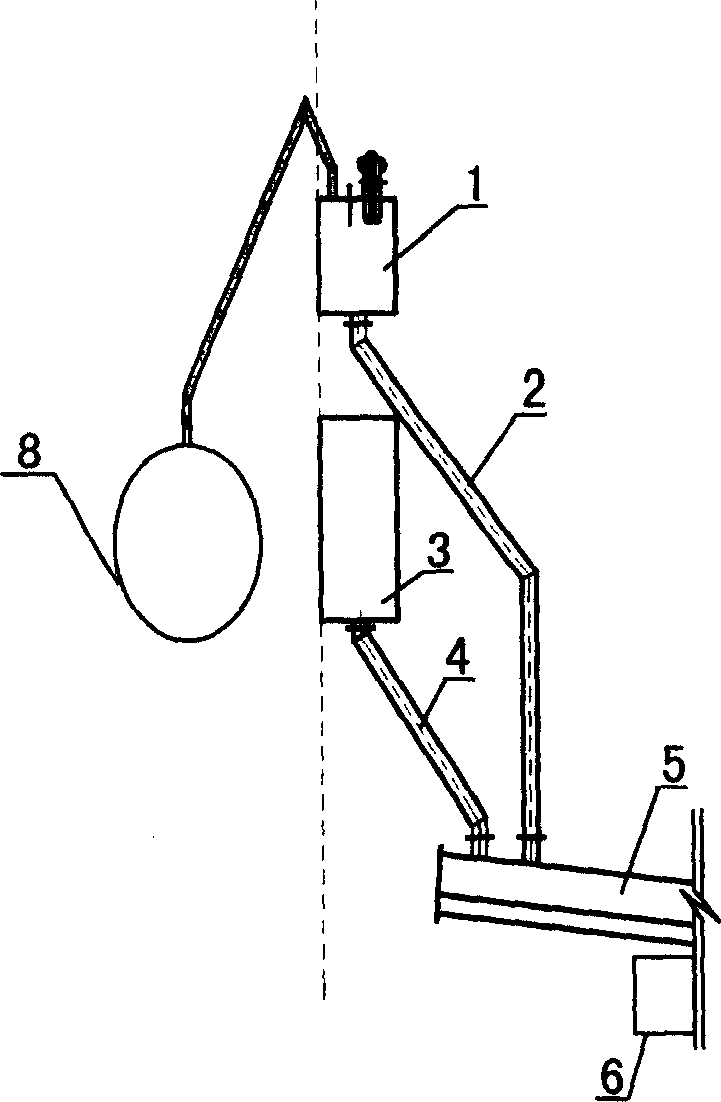

[0009] Embodiments of the present invention: during specific implementation, the charging box (6) on the existing aluminum electrolytic cell and the alumina side wall material box (3) fixed on the side of the aluminum electrolytic cell and the blanking chute connected thereto can be directly utilized Pipe (4), a pneumatic chute (5) is installed on the feeding box (6), so that the discharge port of the pneumatic chute (5) is inserted in the feeding box (6), and the pneumatic chute (5) in the prior art can be directly used. Install the finished product of the moving chute, then fix an aluminum fluoride side wall material box (1) on the wall next to the aluminum electrolytic cell and install a discharge chute (2) connected with the aluminum fluoride side wall material box (1) , the volume G of the aluminum fluoride side wall material box (1) is controlled in the range of: 180 kg≤G≤220 kg, and the smoke exhaust pipe (8) of the electrolysis workshop is passed through the pipeline (9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com