A kind of reaction heat extraction method of hydroformylation synthesizer

A technology of chemical synthesis and hydroformyl, applied in chemical instruments and methods, carbon monoxide reaction preparation, organic chemistry, etc., can solve problems such as heat exchanger leakage, consumption, and large loss of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] specific implementation

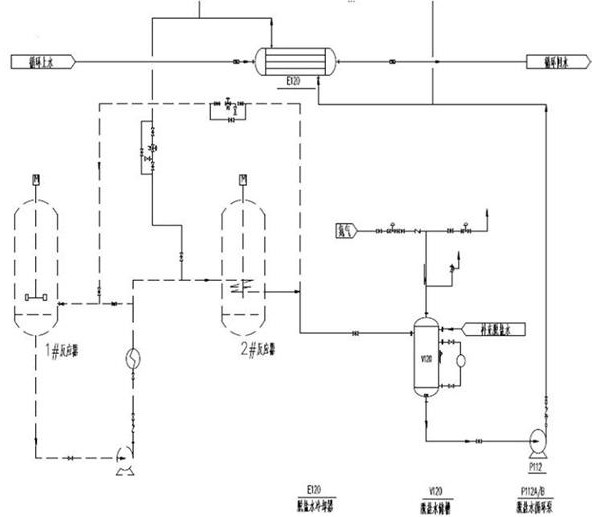

[0017] Using olefins, carbon monoxide and hydrogen as raw materials, olefins, carbon monoxide and hydrogen are reacted in two series-connected formylation synthesis reactors under the action of water-soluble catalysts at a pressure of 2.8-3.0 MPa and a temperature of 80°C-110°C Generate mixed aldehydes, the reaction process releases a large amount of heat, and the heat of reaction is about 125KJ / mol: the reaction solution of the 1# hydroformylation synthesis reactor enters the 1# reactor cooler through the circulating water to cool down and take heat from 110 ℃ is lowered to 60 ℃, and part of the reaction solution after being cooled by the cooling water is returned to the 1# hydroformylation synthesis reactor, and the other part enters the coil of the 2# hydroformylation synthesis reactor. The heat generated by the formylation synthesis reactor is cooled to obtain heat;

[0018] The heat released during the reaction process of 2# hydroformylat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com