Alkali-free liquid setting accelerator preparation method

A technology of quick-setting agent and liquid, which is applied in the field of preparation of non-alkali liquid quick-setting agent, which can solve the problems of large specific surface area of particles, increase stability, and strict equipment requirements, and achieve the effect of shortening the initial and final setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

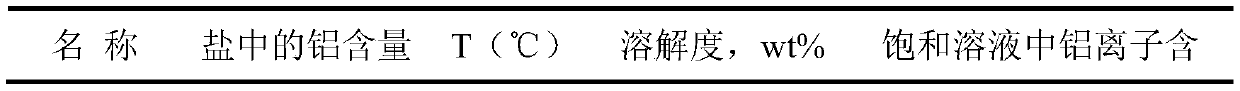

[0035] The "preparation method of an alkali-free liquid quick-setting agent" of the present invention includes: weighing set amounts according to mass percentages: aluminum sulfate, phosphate fertilizer production waste liquid, aluminum hydroxide, sodium silicate and water, and preparing SiO 2 Particles of aluminum fluoride liquid, prepared uniformly dispersed with SiO 2 The aluminum fluoride mother liquor of particles, the mother liquor and the sodium silicate and aluminum sulfate solution are mixed and stirred uniformly to prepare an alkali-free liquid quick-setting agent; the fluorosilicic acid comes from the by-product of phosphate fertilizer production, and the reaction involved in preparing the aluminum fluoride mother liquor The formula is as follows:

[0036] H 2 SiF 6 +2Al(OH) 3 →2AlF 3 +SiO 2 +4H 2 O

Embodiment 1

[0039] S1: Weigh separately by mass percentage: aluminum sulfate 35%, fluorinated silicic acid-containing phosphate fertilizer production waste liquid 33%, aluminum hydroxide 16%, sodium silicate 2%, water 32%, spare.

[0040] S2: Filter the phosphate fertilizer production waste liquid prepared in step S1, concentrate the filtrate, and control solution H by titration + Concentration 5.2~5.3mol / L, then add aluminum hydroxide and stir to obtain SiO 2 Granular aluminum fluoride liquid.

[0041] S3: Using a homogenous disperser, the SiO 2 The granular aluminum fluoride liquid is homogenized to make uniformly dispersed SiO 2 A mother liquor of particulate aluminum fluoride.

[0042] S4: Mix the aluminum fluoride mother liquor prepared in step S3, aluminum sulfate and sodium silicate weighed in step S1, and stir until uniform, to obtain an alkali-free liquid quick-setting agent.

[0043] In each step of Example 1, the reaction temperature should be controlled ≤ 25°C, the mass of fluorosilici...

Embodiment 2

[0045] S1: Weighed by mass percentages: 37% aluminum sulfate, 25% fluorinated silicic acid-containing phosphate fertilizer production waste liquid, 13% aluminum hydroxide, 2.5% sodium silicate, and 35.5% water.

[0046] S2: Filter the phosphate fertilizer production waste liquid prepared in step S1, concentrate the filtrate, and control solution H by titration + Concentration 5.2~5.3mol / L, then add aluminum hydroxide and stir to obtain SiO 2 Granular aluminum fluoride liquid.

[0047] S3: Using a homogenous disperser, the SiO 2 The granular aluminum fluoride liquid is homogenized to make uniformly dispersed SiO 2 A mother liquor of particulate aluminum fluoride.

[0048] S4: Mix the aluminum fluoride mother liquor prepared in step S3, aluminum sulfate and sodium silicate weighed in step S1, and stir until uniform, to obtain an alkali-free liquid quick-setting agent.

[0049] In each step of the second embodiment, the reaction temperature should be controlled ≤ 25°C, the mass of fluoros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com