Hydrated crystal nucleus concrete coagulation accelerating early strength agent and preparation method thereof

A technology of accelerating early strength and concrete, which is applied in the field of concrete additives, can solve the problems of slow cement hydration rate, insufficient super early strength performance and accelerating effect, and crystal nucleus agglomeration, so as to promote cement hydration and shorten the mold Turnover period, effect of improving early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

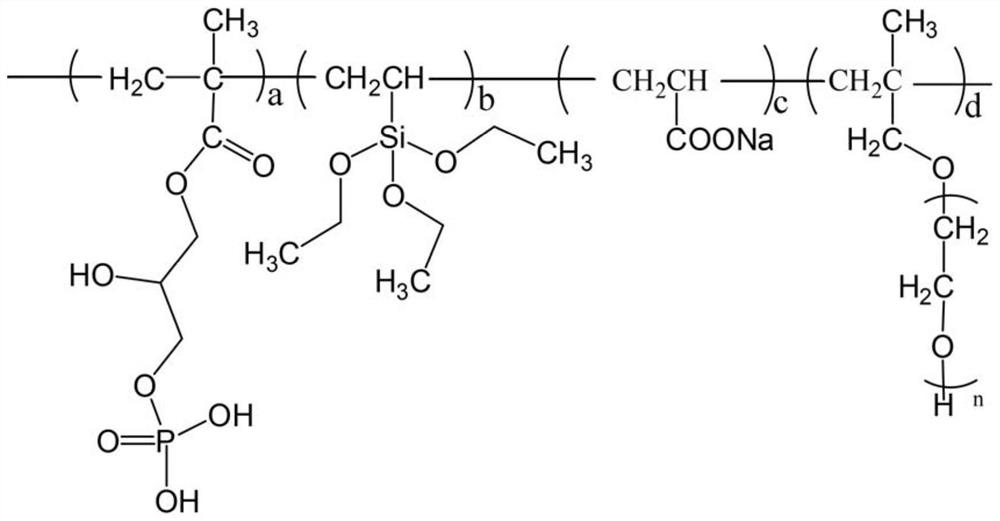

[0035] The preparation method of the water-soluble polymer dispersant of the present embodiment, described method comprises the following steps:

[0036] (1) Add glycidyl methacrylate and phosphoric acid with a molar mass ratio of 1:1 in the flask, under nitrogen protection, stir magnetically at room temperature until the acid value is constant, and obtain phosphonate monomer A; phosphonate monomer A The synthetic route of is shown in the following formula

[0037] (2) Add measured isobutenol polyoxyethylene ether (HPEG4000) and measured deionized water into the four-necked flask, stir, heat up to 35°C, when the isobutenol polyoxyethylene ether (HPEG4000) is completely dissolved, add Hydrogen peroxide, after 5 minutes, respectively dropwise add the aqueous solution of phosphonate monomer, the aqueous solution of vinyltriethoxysilane, the mixed aqueous solution of acrylic acid and mercaptopropionic acid, and the aqueous solution of sodium sulfite to the four-necked flask resp...

Embodiment 2

[0044] The preparation method of the water-soluble polymer dispersant of the present embodiment, described method comprises the following steps:

[0045] (1) Add glycidyl methacrylate and phosphoric acid with a molar mass ratio of 1:1 in the flask, under nitrogen protection, stir magnetically at room temperature until the acid value is constant, and obtain phosphonate monomer A; phosphonate monomer A The synthetic route of is shown in the following formula

[0046] (2) Add metered prenol polyoxyethylene ether (TPEG4000) and metered deionized water into the four-necked flask, stir, heat up to 35°C, when prenol polyoxyethylene ether (TPEG4000) dissolves After completion, add hydrogen peroxide, and add phosphonate monomer aqueous solution, vinyltriethoxysilane aqueous solution, acrylic acid and mercaptopropionic acid mixed aqueous solution, and sodium sulfite aqueous solution to the four-necked flask at the same time dropwise after 5 minutes, and control the dropping time 3h, ...

Embodiment 3

[0053] The preparation method of the water-soluble polymer dispersant of the present embodiment, described method comprises the following steps:

[0054] (1) Add glycidyl methacrylate and phosphoric acid with a molar mass ratio of 1:1 in the flask, under nitrogen protection, stir magnetically at room temperature until the acid value is constant, and obtain phosphonate monomer A; phosphonate monomer A The synthetic route of is shown in the following formula

[0055] (2) Add metered allyl polyoxyethylene ether (APEG2400) and metered deionized water into the four-necked flask, stir, heat up to 35°C, when allyl polyoxyethylene ether (APEG2400) is completely dissolved , adding hydrogen peroxide, and 5 minutes later, respectively dropwise adding aqueous solution of phosphonate monomer, aqueous solution of vinyltriethoxysilane, mixed aqueous solution of acrylic acid and mercaptopropionic acid, and aqueous solution of sodium sulfite to the four-necked flask respectively. Control th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com