Method for producing aluminum fluoride

A production method and technology of aluminum fluoride, applied in aluminum fluoride, aluminum halide and other directions, can solve the problems of large investment in dry process equipment, high production process raw material prices, and high production costs, and achieve abundant reserves and good promotion and application value. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

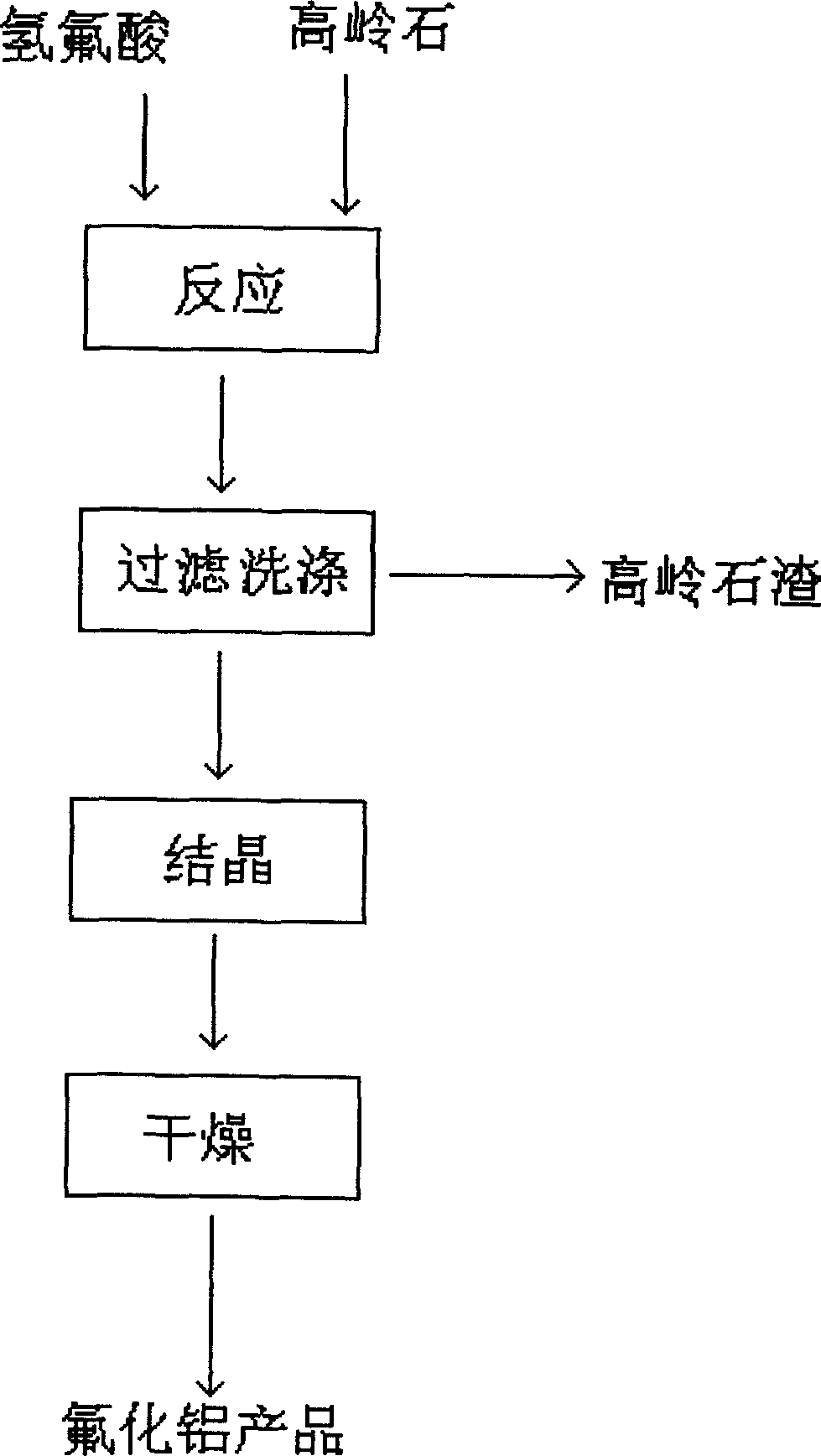

Method used

Image

Examples

Embodiment 1

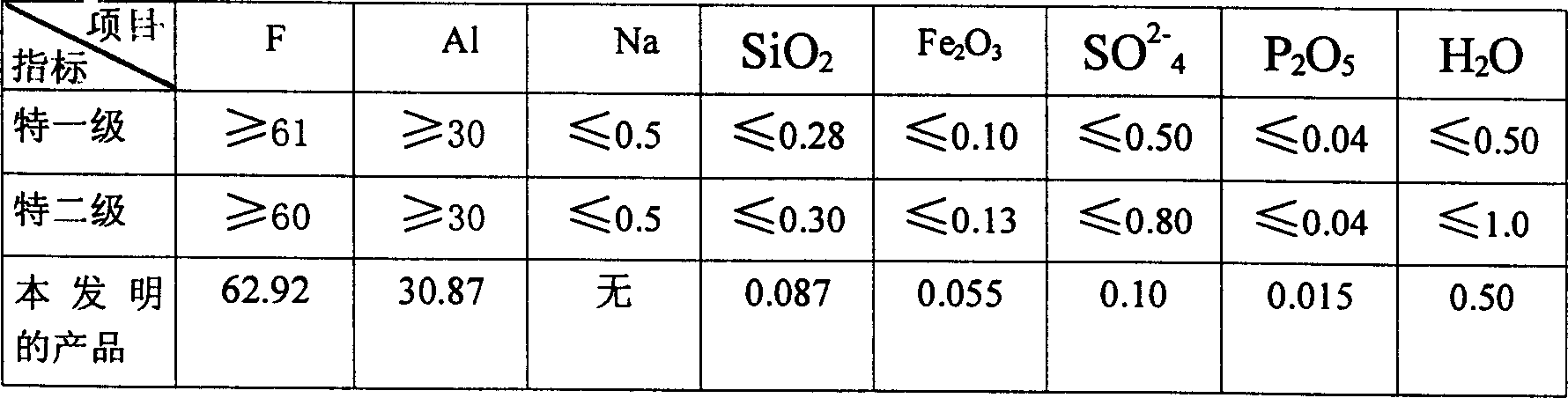

[0018] The method for producing aluminum fluoride of the present invention is as follows: first, 500g of hydrofluoric acid with a concentration of 30% is heated to 60°C, and reacted with 560g of calcined kaolinite, and 560g of water is added during the reaction, the reaction temperature is 85°C, and the reaction time is For 15 minutes, control the pH at the end of the reaction to 1.5. After the reaction, fully filter and wash the kaolin slag. The filtrate obtained is an aluminum fluoride solution, and then the aluminum fluoride solution is crystallized to obtain aluminum fluoride trihydrate, and then dried Dehydration to produce aluminum fluoride products.

Embodiment 2

[0020] The method for producing aluminum fluoride in this embodiment is as follows: firstly heat 750g of hydrofluoric acid with a concentration of 20% to 70°C, then react with 550g of calcined kaolinite, and add 310g of water, the reaction temperature is 90°C, and the reaction time is For 20 minutes, control the pH at the end of the reaction to 2.0. After the reaction is over, filter and wash the kaolin slag, and the obtained filtrate is an aluminum fluoride solution, and then crystallize the aluminum fluoride solution to obtain aluminum fluoride trihydrate, and then dry and dehydrate , to produce aluminum fluoride products.

Embodiment 3

[0022] The method for producing aluminum fluoride of the present embodiment is as follows: 375g concentration is 20% hydrofluoric acid and 370g calcined kaolinite react, add 500g water in the reaction process, reaction temperature 95 ℃, reaction time 25 minutes, control The pH at the end of the reaction is 3.0. After the reaction is finished, filter and wash the kaolin slag, and the obtained filtrate is aluminum fluoride solution, and then the aluminum fluoride solution is crystallized to obtain aluminum fluoride trihydrate, and then dried and dehydrated to obtain fluoride Aluminum products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com