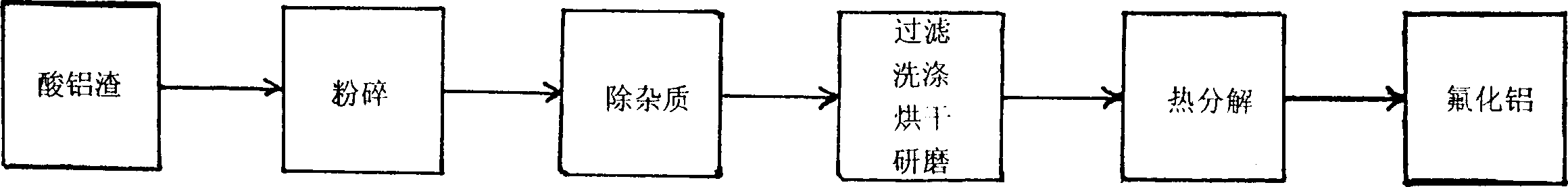

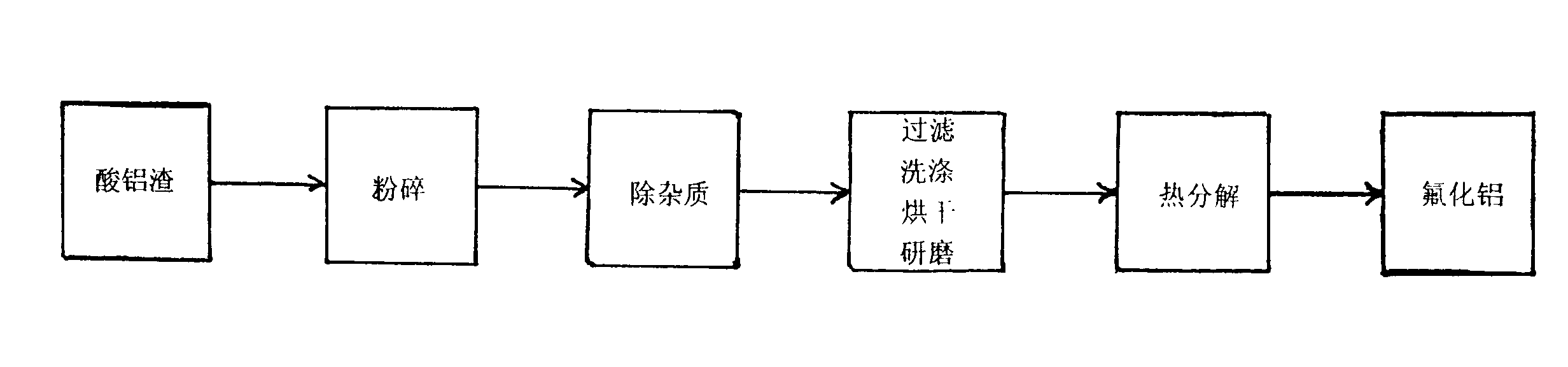

Process for preparing industrial aluminium fluoride from acidic aluminium slag

A technology of aluminum fluoride and aluminum acid, applied in the field of chemical industry, can solve the problems of large number of equipment, complex process and high cost, and achieve the effect of using less equipment, simple process and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described in further detail below in conjunction with accompanying drawing:

[0012] 1. The formation of acid aluminum slag:

[0013] The definition of acid aluminum slag: refers to the solid mixture (mainly containing fluorine elements, aluminum elements, ammonium root) formed after the surface acid corrosion of aluminum profiles with chemical corrosion solution, which is called acid aluminum slag.

[0014] The aluminum profile industry uses a large amount of aluminum ingots, which are converted into aluminum profiles by adding a small amount of silicon powder. The surface of the extruded aluminum profile is a layer of aluminum oxide, which has a metallic luster and is not beautiful. The surface needs to be treated with acid or alkaline chemical mixture for surface corrosion. The acid corrosion method developed in recent years has a good effect. Almost all aluminum profiles now require surface chemical corrosion treatment, most of which are ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com