Computer real-time control method for monitoring temperature trend of aluminum cell

A real-time control and computer technology, applied in the field of automatic control of aluminum electrolytic cell production, can solve the problems of inability to monitor the superheating degree of electrolytic cell in real time, poor real-time performance of energy balance control, automatic control of aluminum electrolytic cell, etc. Real-time monitoring, reducing management intensity and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

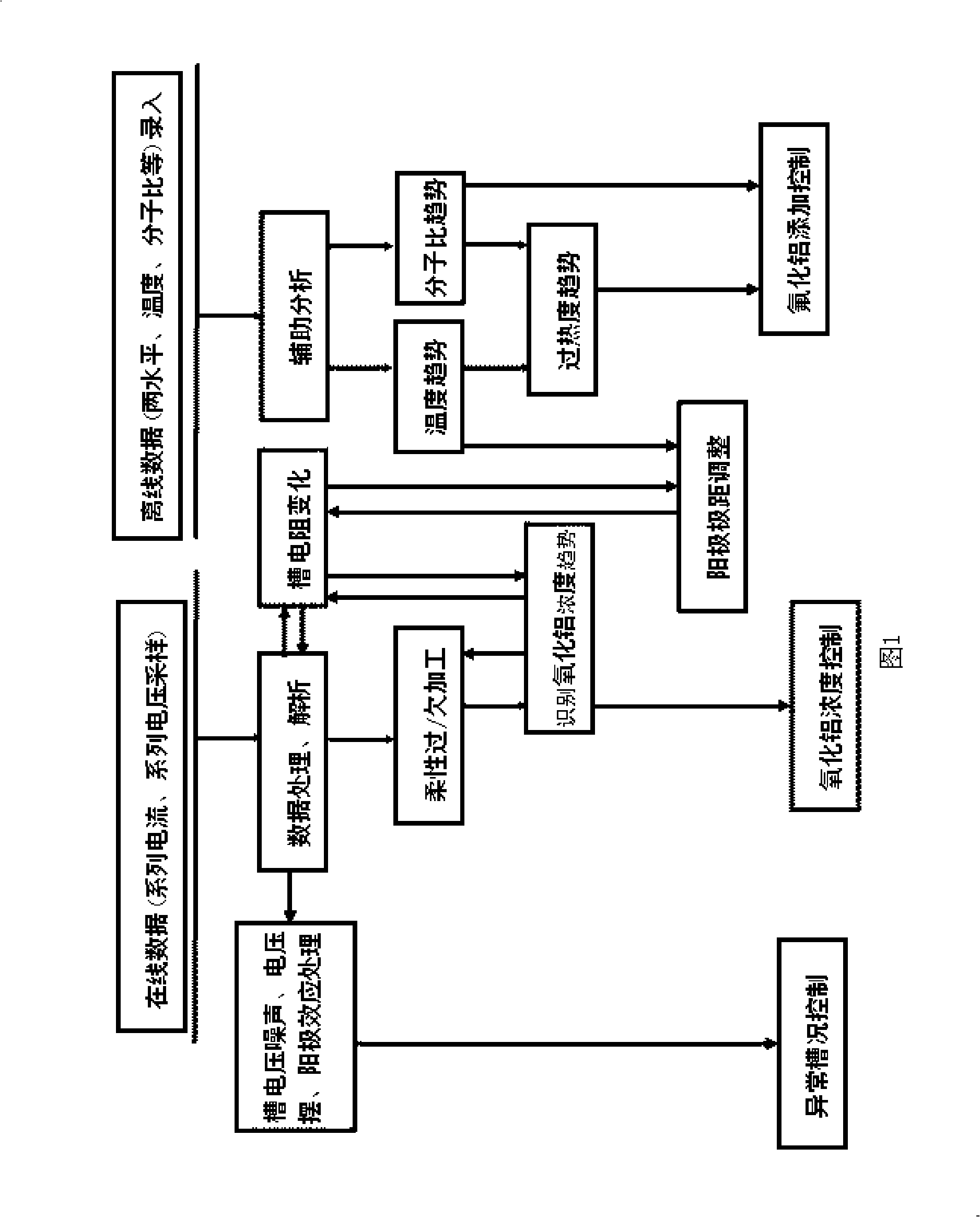

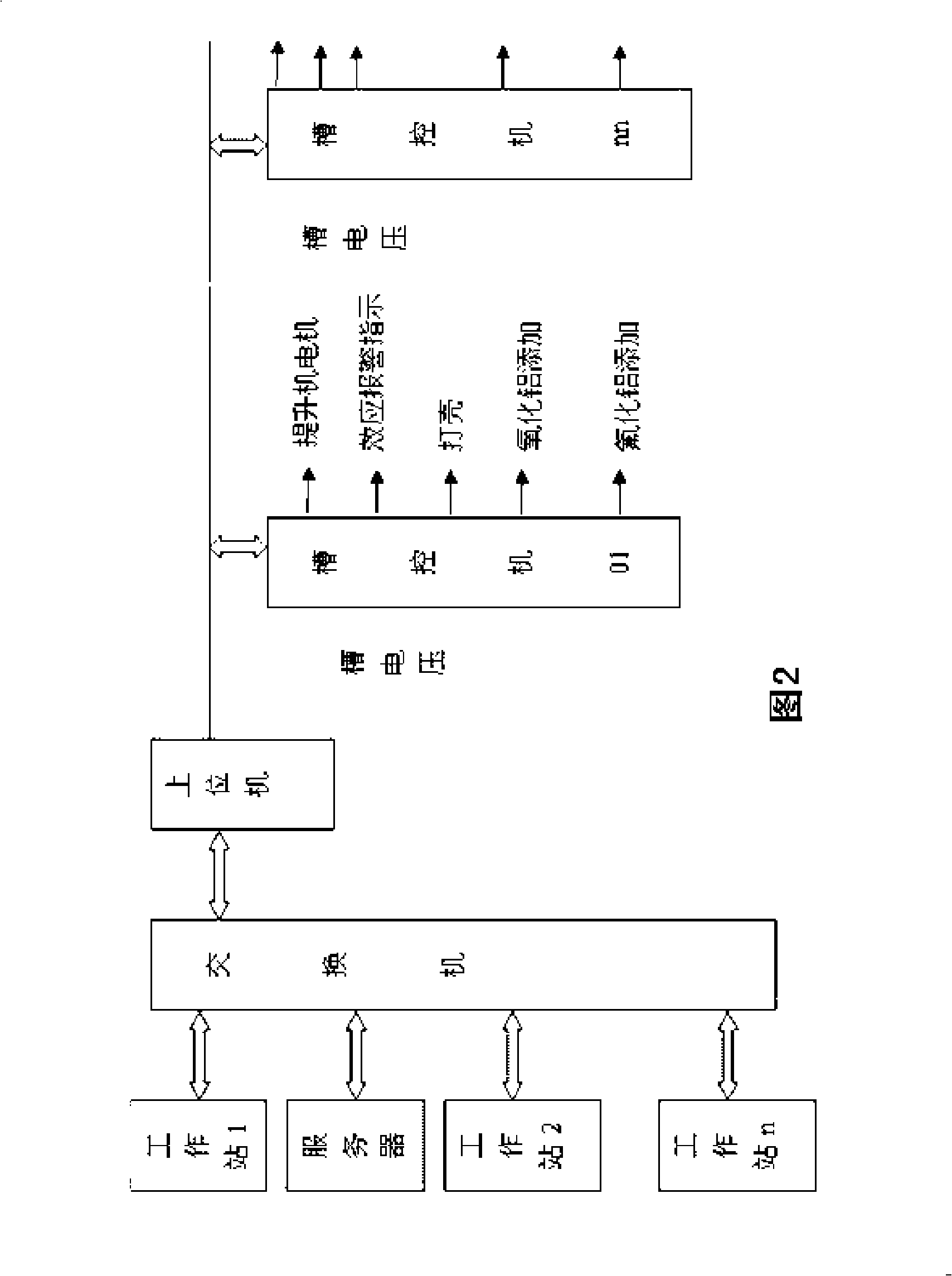

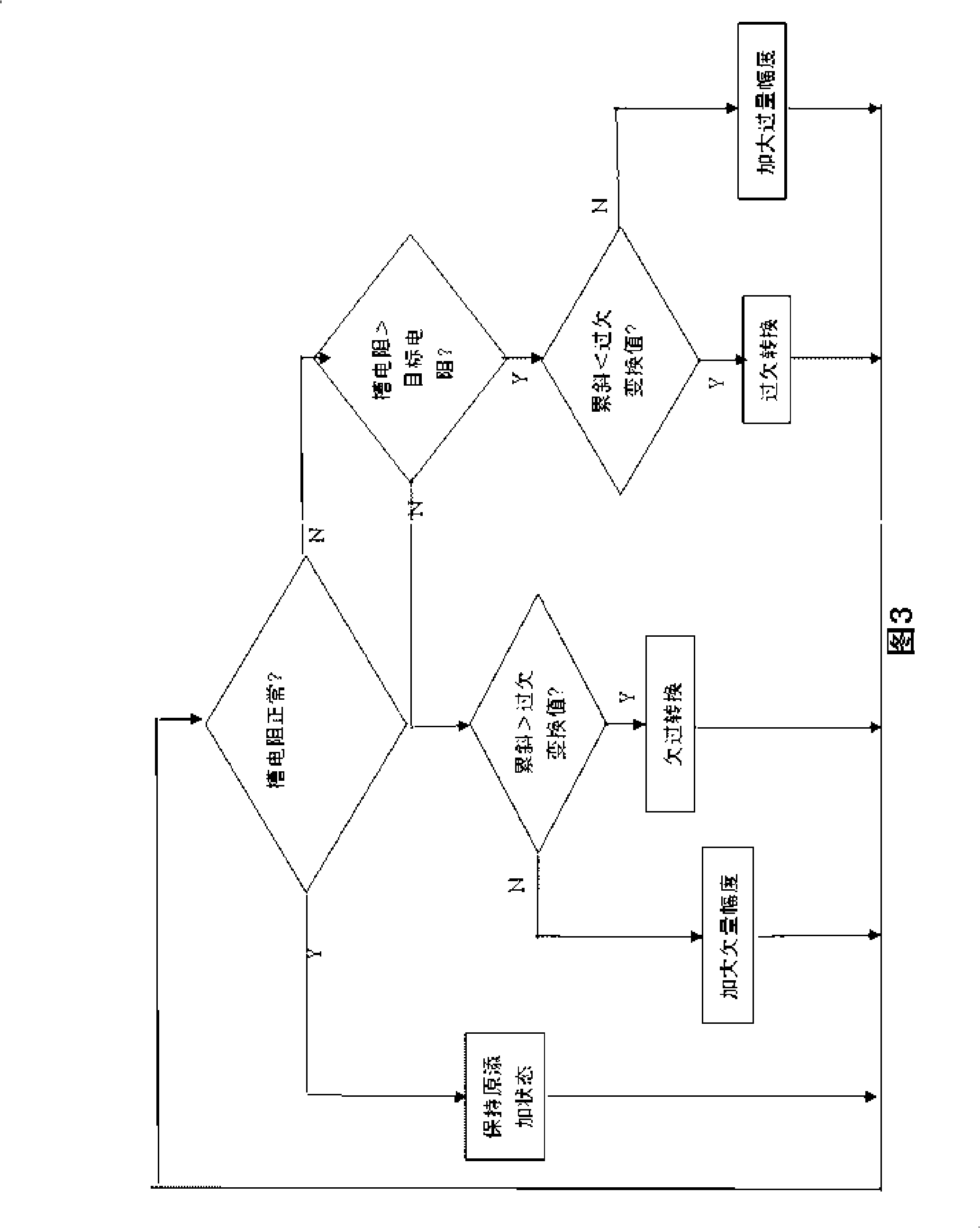

[0027] Figure 1, Figure 2, Figure 3 and Figure 4As shown, the computer real-time control method for the cold and heat trend of aluminum electrolysis of the present invention includes a cell voltage analysis control step, an alumina addition rate control step, and an aluminum fluoride addition rate control step. In the cell voltage analysis control step, the cell voltage is controlled. Real-time analysis, calculate the amplitude variable according to the voltage change curve, including instantaneous amplitude and analytical period amplitude;

[0028] Set the target voltage control step. The initial value of the target voltage is equal to the set voltage. The set voltage is set within the range of the upper limit of the safe voltage and the lower limit of the safe voltage. At the end of each analysis cycle, according to the analysis results of the tank voltage, the set v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com