Charging method of adding aluminium fluoride into electrolytic bath fluoride salt material box and its charging device

The technology of a feeding device and a feeding method is applied in the field of adding aluminum fluoride to the fluoride salt feed box on the electrolytic cell and the feeding device field, which can solve the problems of increasing the production cost of the electrolytic aluminum plant, difficulty in timing and quantification, and large material loss and other issues, to achieve the effects of reducing operating costs and material losses, improving electrolysis production efficiency, and ensuring equipment operation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The determination and timing arrangement of the amount of aluminum fluoride.

[0018] First of all, it is necessary to determine the amount of aluminum fluoride required per day for each electrolyzer. In the production of electrolyzers, a small amount of aluminum fluoride is required every day, and this amount can be calculated according to the following formula: Q 1 =(Q / 365)×0.022Q 1 ——amount of aluminum fluoride required per day, t / day; Q——annual production of primary aluminum, t; According to the shift arrangement of the factory production, the daily delivery time is determined.

[0019] Adding method of aluminum fluoride and configuration of dense phase conveying system.

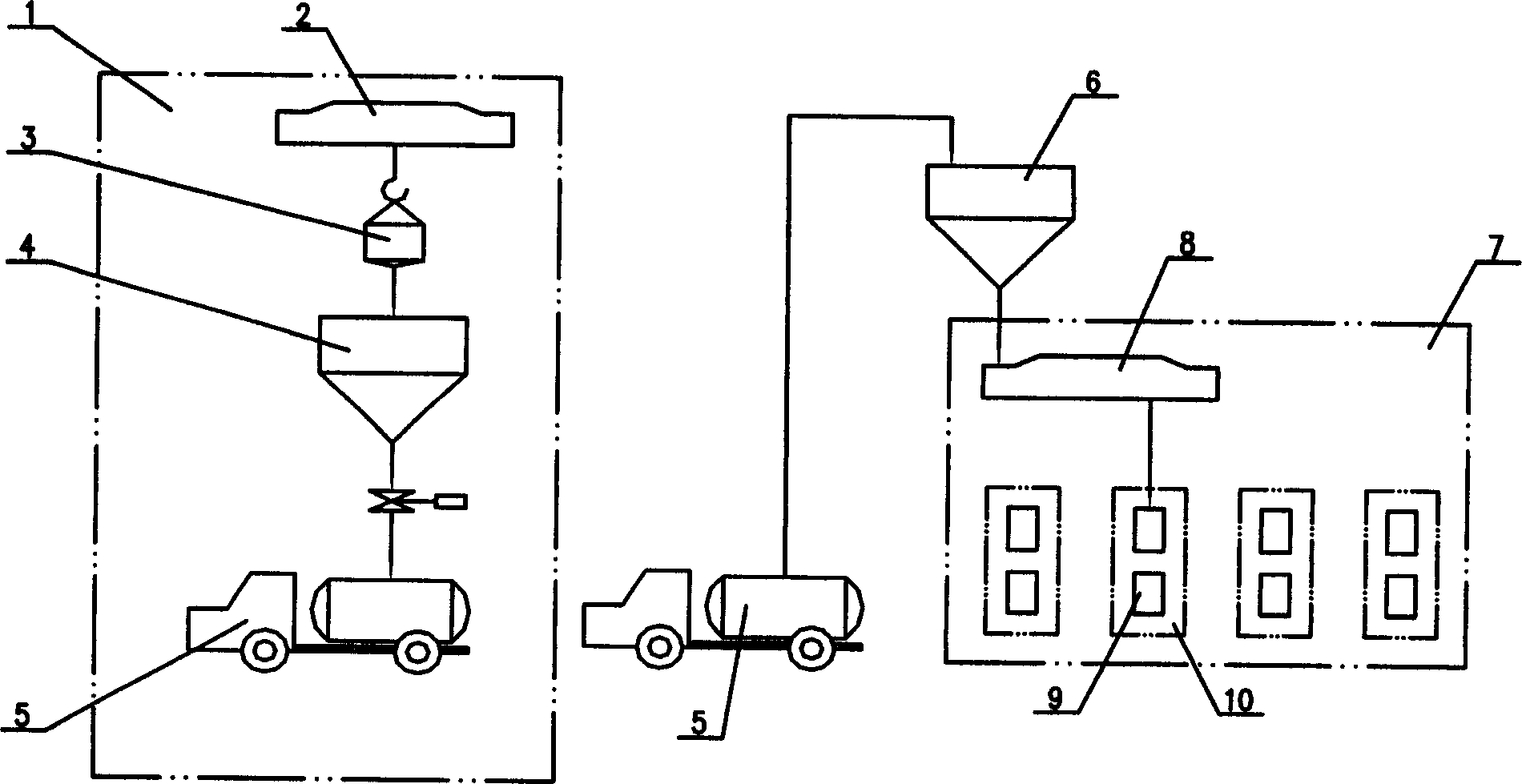

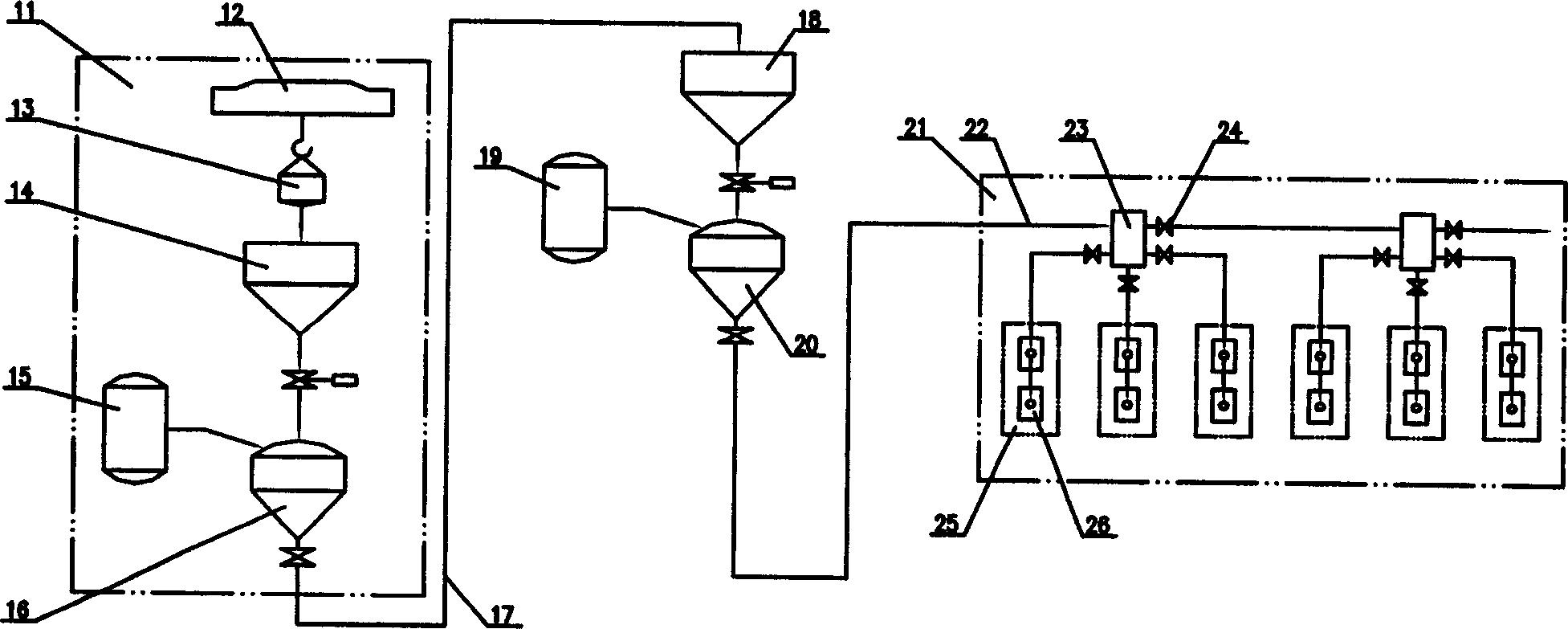

[0020] Aluminum fluoride is added to the electrolytic cell using a dense phase delivery system. After determining the demand for aluminum fluoride and the timing of adding it, the warehouse and the transfer warehouse can respectively determine the use of one, two, three, five or more sets of d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com