Zirconia particles

A technology of zirconia particles and zirconia, applied in zirconia, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as light transmittance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

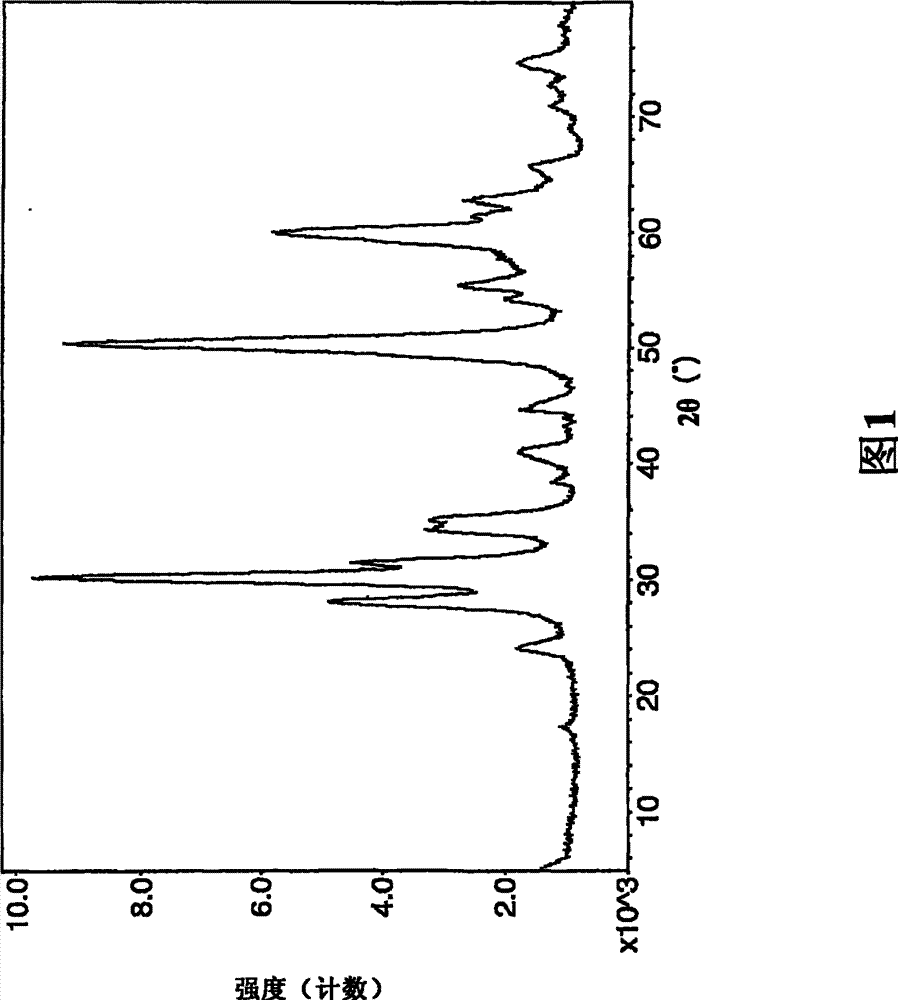

Image

Examples

Embodiment 1

[0162] In a glass vessel, MEEAA (130.55 grams) was dissolved in a zirconium acetate solution (735 grams). The mixture (ie, the aqueous precursor solution) was placed in a large flat glass dish and dried overnight in a forced-air oven at 75°C to 85°C to obtain 322 grams of dry mixed salt (ie, the concentrated precursor).

[0163] A sample (54 grams) of the dry mixed salt was dissolved in 900 grams of DI water. The clear solution was placed in a 2 liter PARR high pressure reaction vessel equipped with a stirrer. The reactor was purged with nitrogen and heated electrically with stirring to a temperature of 185°C. The mixture was maintained at 185°C for 15 minutes, then the oven was switched off and the mixture was stirred for an additional 15 minutes. At this point, remove the container from the heater and cool rapidly in an ice-water bath. This step provides a liquid phase and a solid phase. The liquid was siphoned off and the solid phase was placed in a glass dish and place...

Embodiment 2

[0167] In a glass vessel, MEEAA (130.55 grams) was dissolved in a zirconium acetate solution (735 grams). The mixture was placed in a large flat glass dish and dried overnight in a forced air oven at 75°C to 85°C to obtain 322 grams of dry mixed salt.

[0168] A sample (30 grams) of dry mixed salts was dissolved in 985 grams of DI water. The clear solution was placed in a 2 liter PARR high pressure reaction vessel equipped with a stirrer. The reactor was purged with nitrogen and heated electrically to a temperature of 185° C. within 1 hour with stirring. Turn off the electric stove, remove the container from the heater, and cool rapidly in an ice-water bath. This step provides a liquid phase and a solid phase. The liquid was siphoned off and the solid phase was placed in a glass dish and placed in a preheated forced air drying oven at 75°C to 85°C to obtain a light colored brittle material (ie dried solid).

[0169] A sample of the dried solid (2.0 grams) was dispersed in ...

Embodiment 3

[0172] In a glass container, MEEAA (26.46 grams) was dissolved in a zirconium acetate solution (735 grams). The mixture was placed in a large flat glass dish and dried overnight in a forced air oven at 75°C to 85°C to obtain a dry mixed salt.

[0173] A sample (81 grams) of the dry mixed salt was dissolved in 1,350 grams of DI water. The clear solution was placed in a 2 liter PARR high pressure reaction vessel equipped with a stirrer. The reactor was purged with nitrogen and heated electrically with stirring to a temperature of 185°C. The mixture was maintained at 185°C for 15 minutes. At this point the vessel was removed from the heater and rapidly cooled in an ice-water bath. This step provides a liquid phase and a solid phase. The liquid was siphoned off and the solid phase was placed in a glass dish and placed in a preheated forced air drying oven at 75°C to 85°C to obtain a light colored brittle material (ie dried solid). This procedure was repeated three more times ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com