A kind of micron plate zirconium silicate powder and preparation method thereof

A zirconium silicate, micron-scale technology, which is applied in chemical instruments and methods, nanotechnology, silicon compounds, etc., can solve unfavorable industrial production, complex preparation process, and microscopic morphology of zirconium silicate powder does not present micron-scale plates status and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of micron-scale plate-shaped zirconium silicate powder, comprising the steps of:

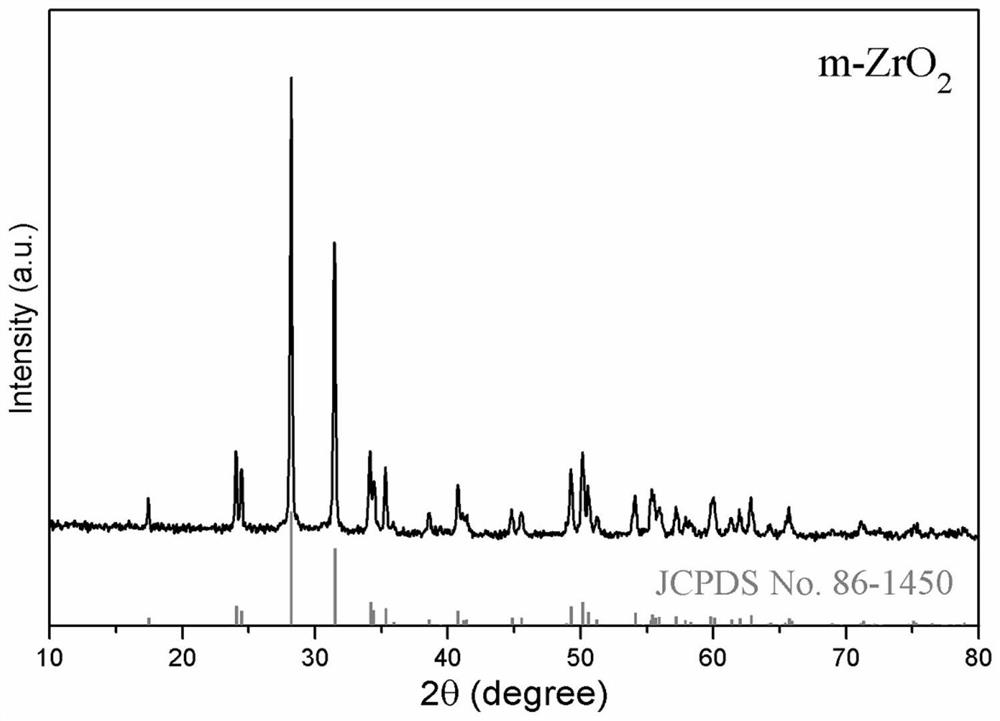

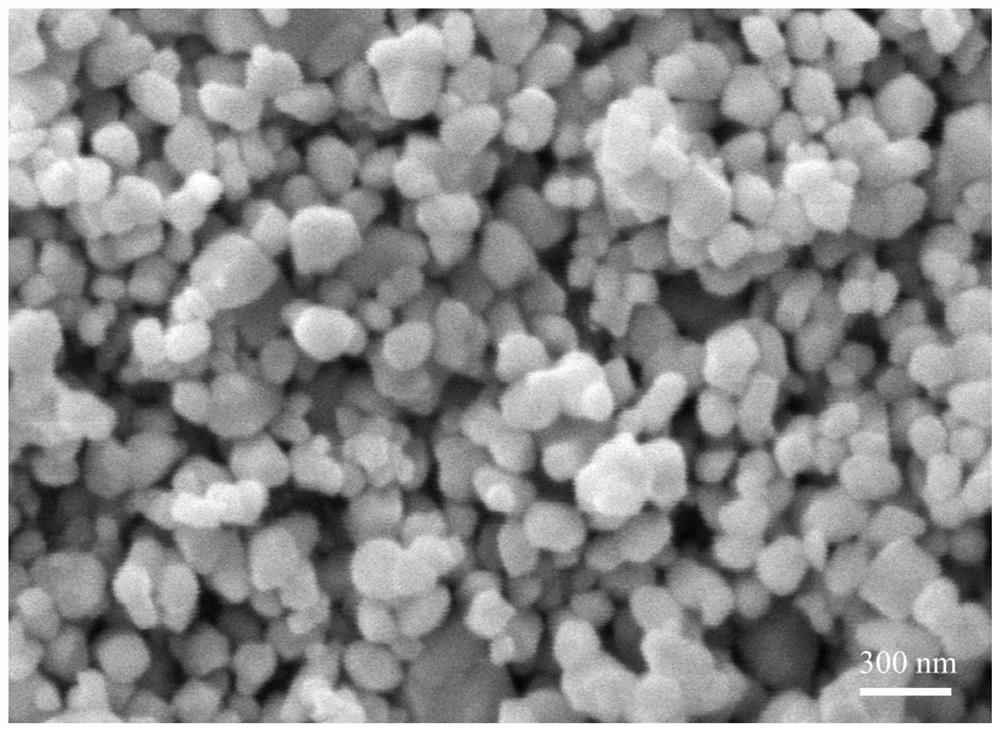

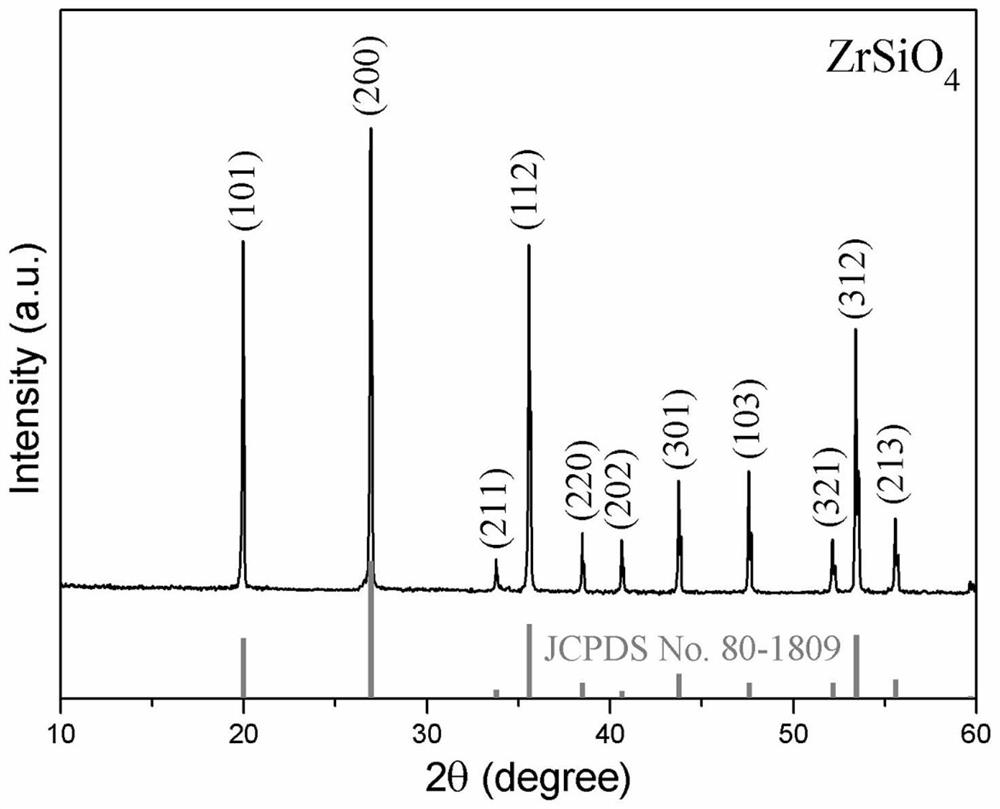

[0035] (1) Take nano-scale monoclinic zirconia ( figure 1 Show its XRD pattern, figure 2 Show its microscopic appearance) 1mol, polycrystalline silicon dioxide 1.05mol, sodium chloride 1mol, dilanthanum trioxide 0.005mol, adopt dry type blender to mix 2 hours, obtain reactant; From figure 1 As can be seen from the shown XRD pattern, the zirconia used is a monoclinic phase; figure 2 It can be seen from the micrograph shown that the zirconia used is nano-spherical particles with a particle size ranging from 100 to 500nm;

[0036] (2) Put the reactant in a crucible, cover and seal it, place it in a muffle furnace and keep it warm at 850°C for 0.5h to obtain a calcined product;

[0037] (3) The calcined product was soaked and washed four times in deionized water at 40° C., then washed twice with ethanol, and dried at 120° C. for 6 hours to obtain micron-sized plate-l...

Embodiment 2

[0045] A preparation method of micron-scale plate-shaped zirconium silicate powder, comprising the steps of:

[0046] (1) Take 3 mol of nano-scale monoclinic zirconia, 3.3 mol of polycrystalline silicon dioxide, 3 mol of sodium chloride, 3 mol of sodium fluoride, 3 mol of potassium chloride, 0.12 mol of strontium oxide, and ball mill and mix for 2 hours to obtain the reactant;

[0047] (2) Put the reactant in a closed sagger, place it in a muffle furnace and keep it warm at 1150° C. for 4 hours to obtain a calcined product;

[0048] (3) The calcined product was soaked and washed twice with deionized water at 100° C., then washed twice with ethanol, and dried at 300° C. for 2 hours to obtain micron-sized plate-like zirconium silicate powder.

[0049] Image 6 The micrograph of the zirconium silicate powder prepared in Example 2 is shown, and it can be seen that the zirconium silicate powder has good crystallization and a plate-like appearance.

[0050] Add 15wt% of the micron...

Embodiment 3

[0054] A preparation method of micron-scale plate-shaped zirconium silicate powder, comprising the steps of:

[0055] (1) Take 2 mol of nano-scale monoclinic zirconia, 2.1 mol of polycrystalline silicon dioxide, 2 mol of potassium chloride, 0.02 mol of dilanthanum trioxide, 0.04 mol of strontium oxide, and ball mill and mix for 2 hours to obtain a reactant;

[0056] (2) Put the reactant in a sealed sagger, place it in a muffle furnace and keep it warm at 950° C. for 2 hours to obtain a calcined product;

[0057] (3) Soak and wash the calcined product in deionized water at 80°C for 4 times, soak and wash in alcohol water once, then wash with ethanol twice, and dry at 80°C for 8 hours to obtain micron-sized flakes. Zirconium silicate powder.

[0058] Add 15wt% micron-sized plate-like zirconium silicate powder prepared in Example 3 to the transparent raw glaze slurry, stir it evenly, spray it on the yellow ceramic green body and dry it at 300°C for 0.5h, Then sintered at 1050°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com