Photochromic multifunctional rubber outsole and preparation method thereof

A photochromic and multi-functional technology, applied in the field of footwear products, can solve the problems of wear resistance and poor rubber resilience, and achieve the effects of low cost, high production efficiency and favorable mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] According to the dosage of the formula in Table 1, the cis-butadiene rubber and the solution-polymerized styrene-butadiene rubber are weighed as the first group, the silica is weighed as the second group, and the remaining materials are weighed as the third group.

[0052] Pour the first group of rubber raw materials into the internal mixer, start the internal mixer, and mix for 8 minutes. When the temperature of the internal mixer rises to 100 °C, mix for 2-3 minutes, and pour the white carbon black into the internal mixer. , Mixing for 8 minutes, when the temperature of the internal mixer rises to 130 ° C, pour the third group of ingredients and mix for 15 minutes, and finally pour out the mixed rubber.

[0053] Pour the mixed rubber into the mill, and roll it continuously for 5-8 times to form a 2mm thick sheet.

[0054] The rubber sheets of the outer layer, the middle layer and the inner layer are respectively produced according to the above steps.

[0055] Cut the...

Embodiment 2-6

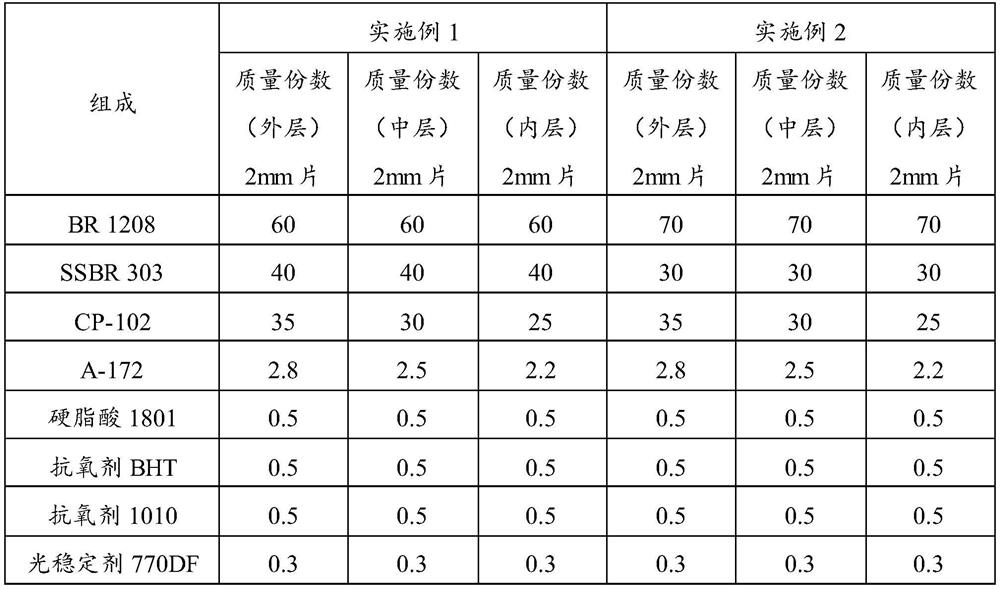

[0058] According to the dosages of the formulas in Table 1, Table 2 and Table 3, and prepared according to the steps of Example 1, a multifunctional and photochromic rubber outsole was obtained respectively.

[0059] Table 1 The formula composition of the rubber outsole material of Example 1-2 of the present invention

[0060]

[0061]

[0062] The formula composition of the rubber outsole material of table 2 embodiment 3-4 of the present invention

[0063]

[0064] The formula composition of the rubber outsole material of table 3 embodiment 5-6 of the present invention

[0065]

[0066]

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com