Continuous manufacturing method for antiskid surface

A production method and anti-slip technology, applied to the device for coating liquid on the surface, special surface, pre-treated surface, etc., can solve the problems of affecting the service life, low production efficiency, easy whitening of the surface, etc., to improve work efficiency, The effect of high production efficiency and short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

[0028] The continuous production method of anti-slip surface of the present invention is realized through the following steps:

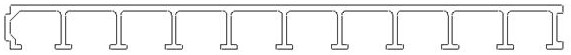

[0029] S1 Pre-treatment: first take a base material 2 to be processed, such as figure 2 As shown, the base material 2 is a pedestrian bridge deck base material, and the surface of the base material 2 is first sanded with a grinder to remove the release agent and other attachments on the surface of the base material 2.

[0030] S2 Waiting for processing: place the ground substrate 2 on a dedicated coating device.

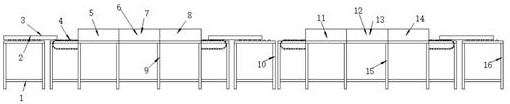

[0031] Such as figure 1 The schematic diagram shown shows that the dedicated coating equipment includes

[0032] The sand adding unit, the sand adding unit includes a sand adding frame 1, on the upper end surface of the sand adding f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com