A kind of compatibilizer and its synthesis method as well as the tpu shoe base material containing this compatibilizer and its synthesis method

A technology of compatibilizer and shoe material, which is applied in the field of compatibilizer and its synthesis, as well as the TPU shoe material base material containing the compatibilizer and its synthesis, which can solve the problems of poor shoe material elasticity, poor anti-slip performance, weather resistance, Poor aging resistance and other problems, to achieve the effect of improving wear resistance and anti-slip performance, improving TPU shoe material, and good aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

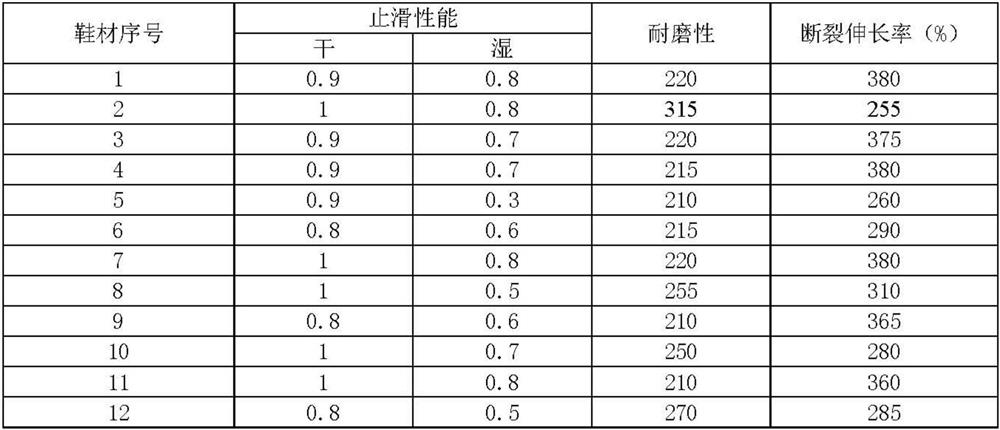

Examples

Embodiment Construction

[0019] In order to clearly illustrate the technical features of the present solution, the present application will be described in detail below through specific implementation modes.

[0020] The compatibilizer obtained in this application has its own independent use, that is, it is used for TPU shoe materials, so this application is characterized based on the synthesis of TPU shoe materials, but it should be noted that the use of this method is not because the compatibilizer is not a separate product , but because the TPU shoe material is used as an end product, the effect of the compatibilizer on its physical and chemical properties is its ultimate goal.

[0021] The test procedure of this application is carried out according to the following steps:

[0022] 1 Synthesis of compatibilizer

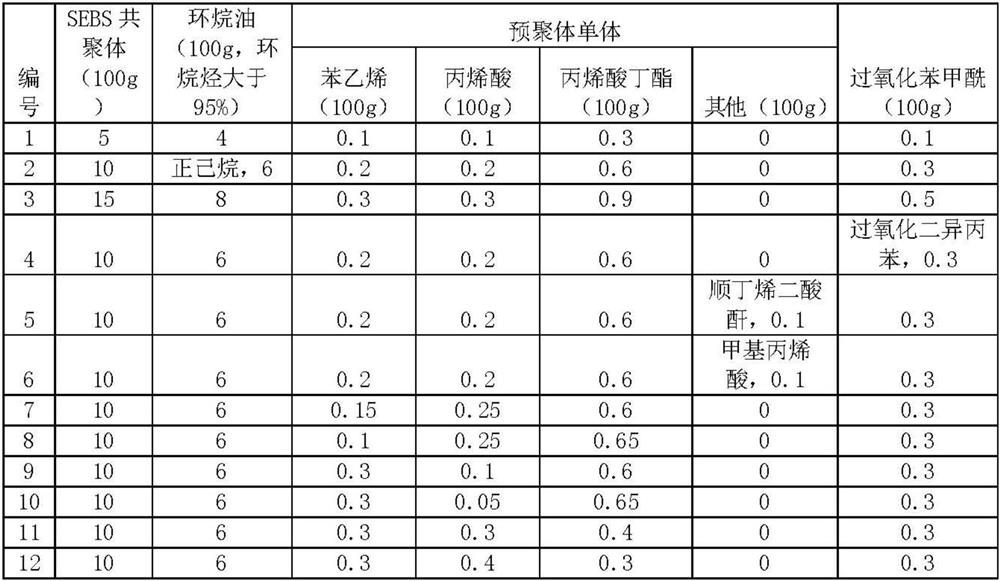

[0023] S1. Blending raw material 1, the components of raw material 1 are shown in Table 1;

[0024] S2. Put the blended raw material 1 into a twin-screw extruder, and perform water ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com