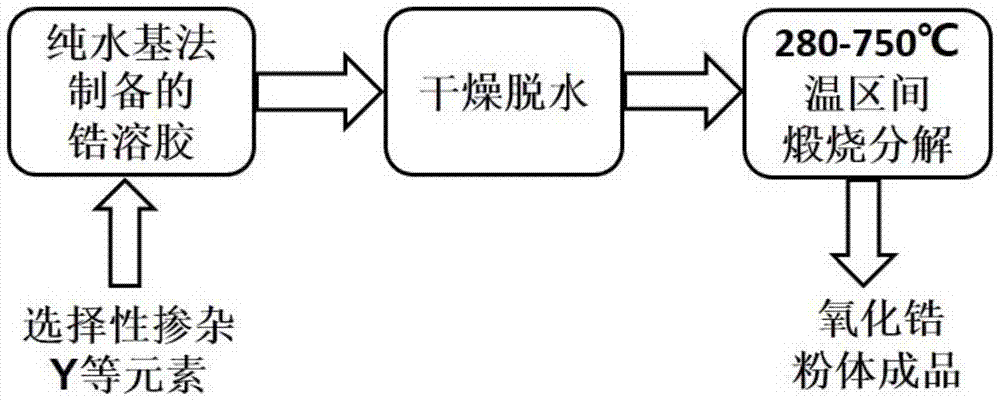

A method of preparing zirconium dioxide nanopowder by calcining zirconium sol at low temperature

A technology of nanopowder and zirconia, applied in zirconia, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

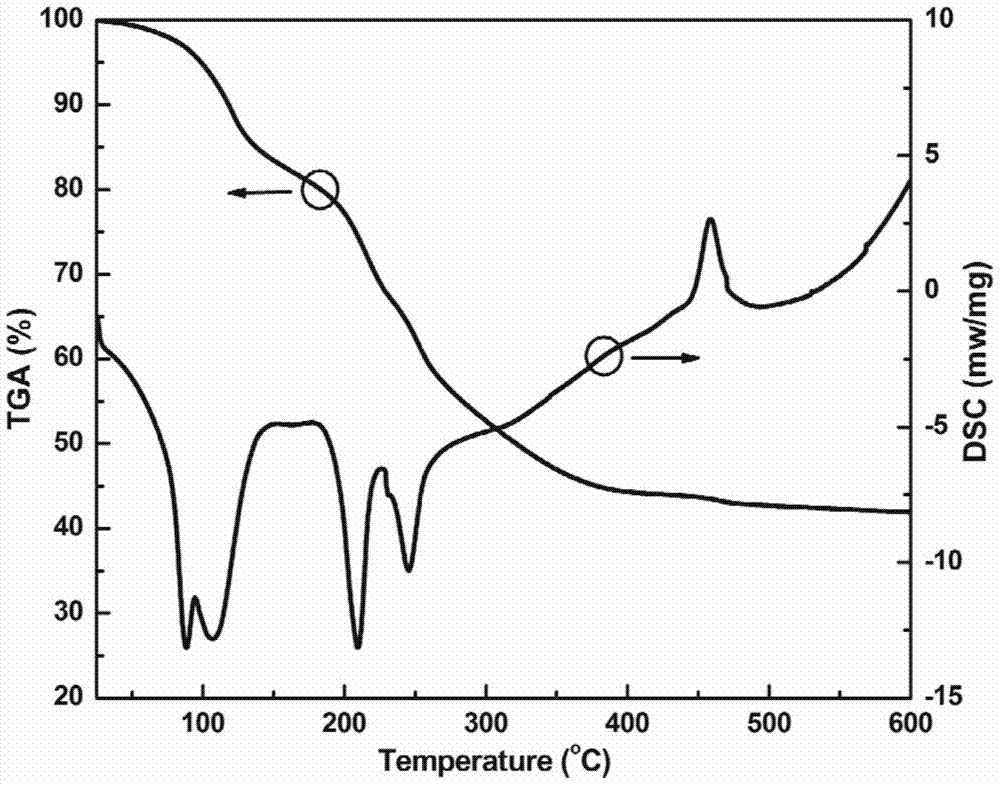

Method used

Image

Examples

Embodiment 1

[0028] Dissolve zirconium oxychloride octahydrate in deionized water to form a clear solution with a concentration of 0.12mol / L, then add 1mol / L ammonia water to form a suspension, and measure the pH value to 7.8; the suspension is centrifuged to obtain Zr(OH ) 4 Hydrate precipitated, washed the precipitate with water to remove chloride ions; then quantitatively added 2mol / L nitric acid and 10mol / L hydrogen peroxide mixture to the precipitate for degumming reaction; vigorously stirred for 1 day to obtain a clear zirconium sol precursor, measured The clear sol has a pH value of 0.8.

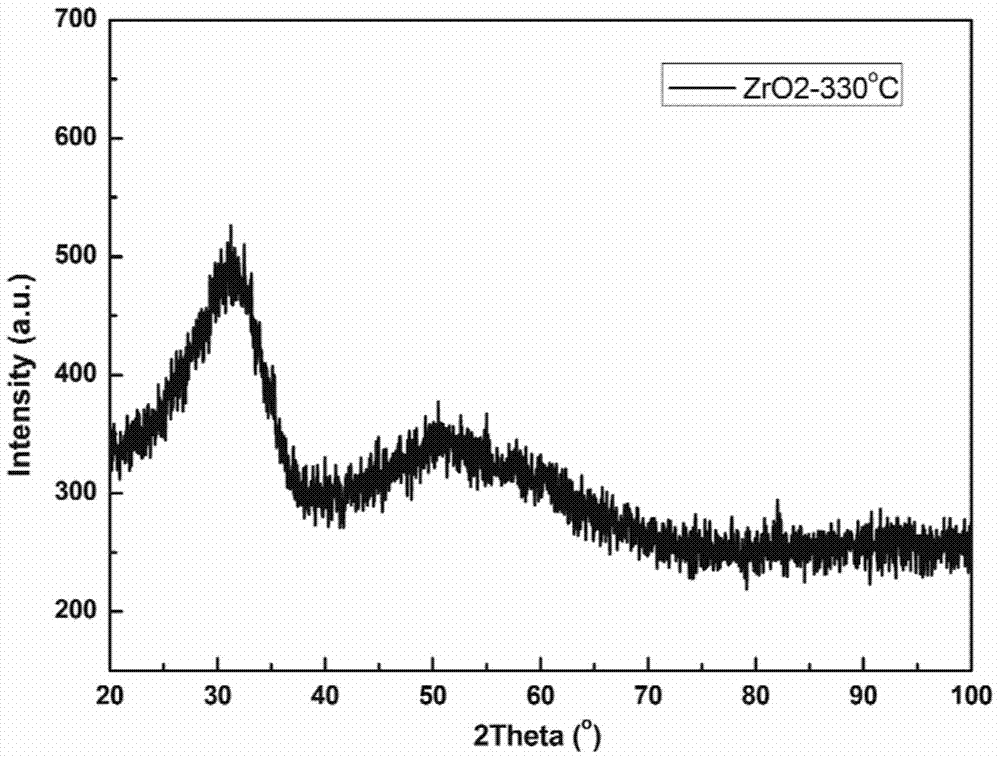

[0029] Filter the clarified zirconium sol precursor to remove possible undissolved precipitated particles; then heat and evaporate water at 70°C to obtain a transparent zirconium xerogel. After the zirconium xerogel is calcined and decomposed at 330° C., the amorphous zirconium dioxide nanopowder is obtained.

[0030] From attached image 3 It can be seen from the X-ray diffraction pattern of t...

Embodiment example 2

[0032] Dissolve zirconium oxychloride octahydrate in deionized water to form a clear solution with a concentration of 0.12mol / L, then add 1mol / L ammonia water to form a suspension, and measure the pH value to 9.0; the suspension is filtered to obtain Zr(OH ) 4 Hydrate precipitated, washed the precipitate with water to remove chloride ions; then quantitatively added 2mol / L nitric acid and 10mol / L hydrogen peroxide mixture to the precipitate for degumming reaction; vigorously stirred for 1 day to obtain a clear zirconium sol precursor, measured The clear sol has a pH of 0.6.

[0033] Filter the clarified zirconium sol precursor to remove possible undissolved precipitated particles; then heat and evaporate water at 75°C to obtain a transparent zirconium xerogel. After the zirconium xerogel is calcined and decomposed at 405°C, the nanometer powder of zirconium dioxide mixed with amorphous amorphous state and tetragonal phase is obtained.

[0034] From attached Figure 4 It can ...

Embodiment example 3

[0036] Dissolve zirconium oxychloride octahydrate in deionized water to form a clear solution with a concentration of 0.12mol / L, then add 1mol / L ammonia water to form a suspension, and measure the pH value to 8.5; the suspension is centrifuged to obtain Zr(OH ) 4 Hydrate precipitated, washed the precipitate with water to remove chloride ions; then quantitatively added 2mol / L nitric acid and 10mol / L hydrogen peroxide mixture to the precipitate for degumming reaction; vigorously stirred for 1 day to obtain a clear zirconium sol precursor, measured The pH value of the clear sol was 0.7.

[0037] Filter the clarified sol precursor to remove possible undissolved precipitated particles; then heat and evaporate water at 80°C to obtain a transparent zirconium xerogel. Finally, the dry gel is calcined and decomposed at 430° C. to obtain a stable tetragonal phase zirconia nanopowder.

[0038] From attached Figure 5 It can be seen from the X-ray diffraction pattern that the powder is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com