A method for preparing α-phenylethyl alcohol using zirconia-silica/graphene hybrid material as a catalyst

A technology of silica and hybrid materials, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the influence of zirconia grain dispersion uniformity, is not suitable for large-scale industrial applications, increases Catalyst energy consumption and other issues to achieve the effect of improving operational safety, reducing reaction energy consumption, and less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

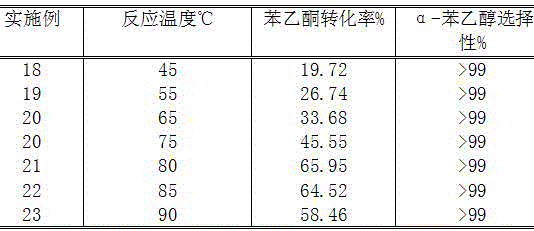

[0027] Example 1-6: Preparation of α-phenylethyl alcohol with different zirconia-silicon ratio zirconia-silicon dioxide / graphene hybrid materials as catalysts

[0028] 1. Preparation methods of zirconia-silicon dioxide / graphene hybrid materials with different zirconium-silicon ratios:

[0029] 1) Preparation of graphene oxide suspension: disperse graphene oxide in 10 ml of ethanol according to Table 1, and obtain a brown-yellow graphene oxide suspension after ultrasonication for 1-3 h;

[0030]2) Preparation of zirconia / silica-graphene wet gel: Mix 3.9 ml zirconyl nitrate, 10 ml ethanol and 15 ml acetic acid, and add to the graphene oxide suspension obtained in step 1), mix well and mark It is solution A; according to the different proportions in Table 1, take tetraethyl orthosilicate (TEOS), mix well with 1.5 ml of water, 1 ml of hydrochloric acid, and 10 ml of ethanol, and mark it as solution B. Add solution B dropwise to solution A, and let stand for 15 min to obtain zirco...

Embodiment 7-10

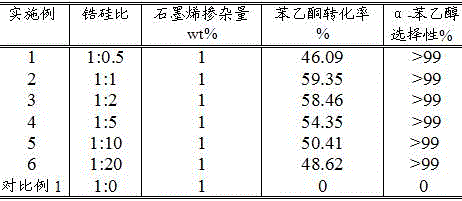

[0043] Example 7-10: The reaction results of preparing α-phenylethyl alcohol with different graphene doping amounts of zirconia-silicon dioxide / graphene hybrid materials as catalysts

[0044] Preparation of zirconia-silicon dioxide / graphene hybrid material with different graphene doping amounts: other conditions are as in Example 1, the difference is that step 1) is doped by different graphene in Table 2 Measure graphite oxide, step 2) Solution B is obtained by mixing 8 ml tetraethyl orthosilicate (TEOS), 1.5 ml water, 1 ml hydrochloric acid and 10 ml ethanol.

[0045] Catalytic reaction conditions: Other conditions are as the catalytic reaction conditions of embodiment 1-6, difference is that embodiment 7-10 adopts 0.2wt%, 0.5wt%, 1wt% and 2wt%ZrO successively 2 -SiO 2 / GO hybrid material as catalyst, the results are shown in Table 2.

Embodiment 11-17

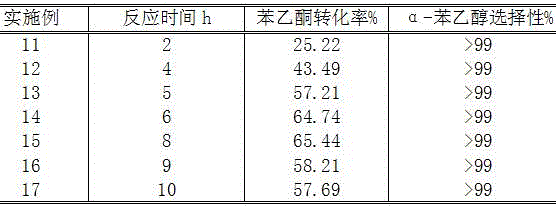

[0053] Embodiment 11-17: the catalytic reaction result of different reaction time

[0054] Other conditions are as the catalytic reaction condition of embodiment 1-6, and difference is that embodiment 11-17 all adopts Zr:Si=1:2, 1wt%ZrO 2 -SiO 2 The / GO hybrid material was used as a catalyst, and different reaction times were used, ranging from 2 to 10 h. The results are shown in Table 3.

[0055] Table 3 Examples 11-17 catalytic reaction results

[0056]

[0057] As can be seen from Table 3, as the reaction time increases, the conversion of acetophenone of the present invention is first improved, and when the reaction exceeds 8 hours, the conversion rate of acetophenone decreases.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com