Hydrotalcite and its production method

A manufacturing method and technology of hydrotalcite, applied in the direction of hydrotalcite, chemical instruments and methods, aluminum compounds, etc., can solve problems such as insufficient quality of synthetic products, and achieve the effect of improving transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

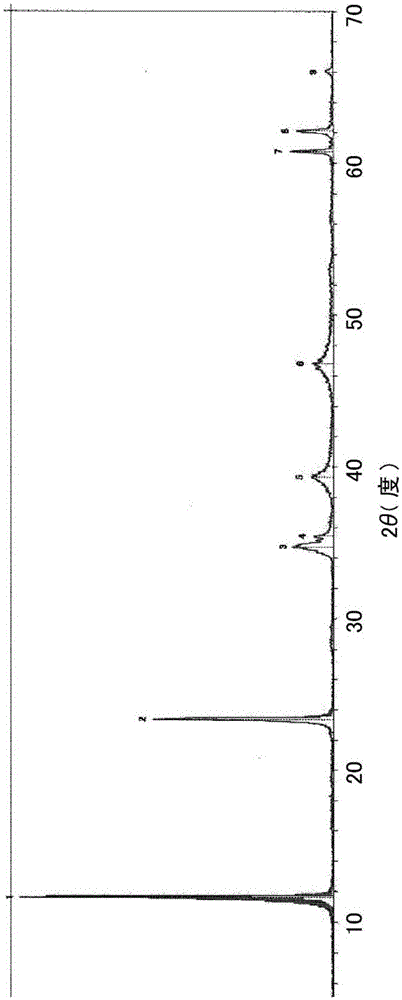

[0131] (Example 1) Production of Hydrotalcite

[0132] In a 5 L container, 447.3 g of magnesium hydroxide (D50=4.0 μm) and 299.2 g of aluminum hydroxide (D50=8.0 μm) were added, water was added to make the total amount 3 L, and a slurry was prepared by stirring for 10 minutes. D50 of this slurry was 10 micrometers, and D90 was 75 micrometers. This slurry was supplied to a wet pulverization device equipped with a cooling unit (DynoMill MULTILAB, manufactured by SHINMARU ENTERPRISES CORPORATION, filled with zirconia beads), and the temperature of the slurry was controlled not to exceed 40°C during pulverization, and wet pulverization treatment was performed for 18 minutes (residence time). As a result, D50 of the slurry was 1.0 μm, D90 was 3.5 μm, and the viscosity of the slurry was 5000 mPa·s. Thereafter, sodium bicarbonate was added to 2 L of the pulverized slurry so as to make it 1 / 2 mole relative to 1 mole of magnesium hydroxide, and the whole was adjusted to 8 L with water...

Embodiment 2

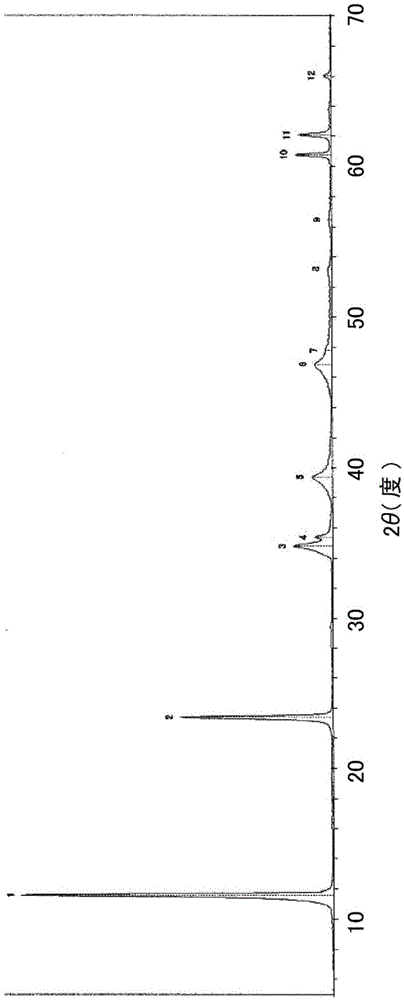

[0133] (Example 2) Manufacture of Hydrotalcite

[0134]In a 5 L container, 447.3 g of magnesium hydroxide (D50=4.0 μm) and 299.2 g of aluminum hydroxide (D50=8.0 μm) were added, water was added to make the total amount 3 L, and a slurry was prepared by stirring for 10 minutes. D50 of this slurry was 10 micrometers, and D90 was 75 micrometers. This slurry was supplied to a wet pulverization device equipped with a cooling unit (DynoMill MULTILAB, manufactured by SHINMARU ENTERPRISES CORPORATION, filled with zirconia beads), and the temperature of the slurry was controlled not to exceed 50°C during pulverization, and wet pulverization treatment was performed for 18 minutes (residence time). As a result, D50 of the slurry was 1.0 μm, D90 was 3.5 μm, and the viscosity of the slurry was 4800 mPa·s. Thereafter, sodium bicarbonate was added to 2 L of the pulverized slurry so as to make it 1 / 2 mole relative to 1 mole of magnesium hydroxide, and the whole was adjusted to 8 L with water...

Embodiment 3

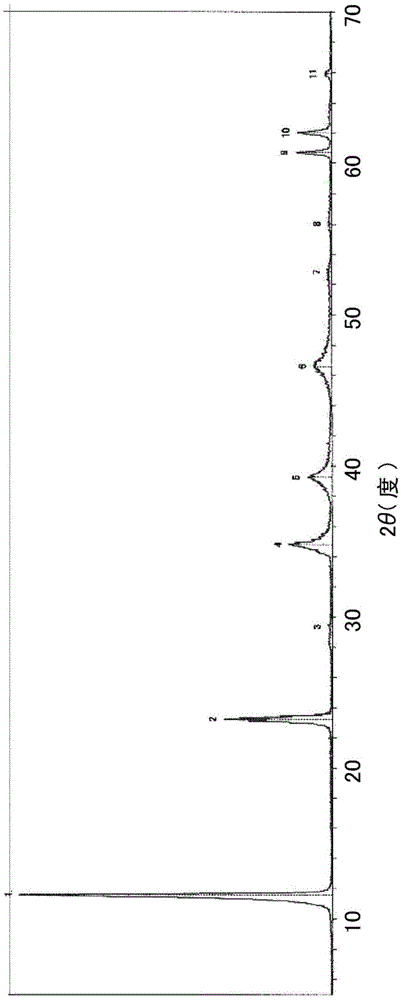

[0142] (Example 3) Production of Hydrotalcite

[0143] In a 5 L container, 447.3 g of magnesium hydroxide (D50=4.0 μm) and 299.2 g of aluminum hydroxide (D50=8.0 μm) were added, water was added to make the total amount 3 L, and a slurry was prepared by stirring for 10 minutes. D50 of this slurry was 10 micrometers, and D90 was 75 micrometers. This slurry was supplied to a wet pulverization device equipped with a cooling unit (DynoMill MULTILAB, manufactured by SHINMARU ENTERPRISES CORPORATION, filled with zirconia beads), and the temperature of the slurry was controlled not to exceed 40°C during pulverization, and wet pulverization treatment was performed for 18 minutes (residence time). As a result, D50 of the slurry was 1.0 μm, D90 was 3.5 μm, and the viscosity of the slurry was 5000 mPa·s. Thereafter, sodium carbonate was added to 2 L of the pulverized slurry so as to make it 1 / 2 mole relative to 1 mole of magnesium hydroxide, and the whole was adjusted to 8 L with water, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com