Chromium free refractory material for RH vacuum furnace lining

A refractory material and vacuum furnace technology, applied in the field of refractory materials, can solve problems such as high production costs, diffusion of harmful substances, and damage to the environment, and achieve the effect of reducing material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

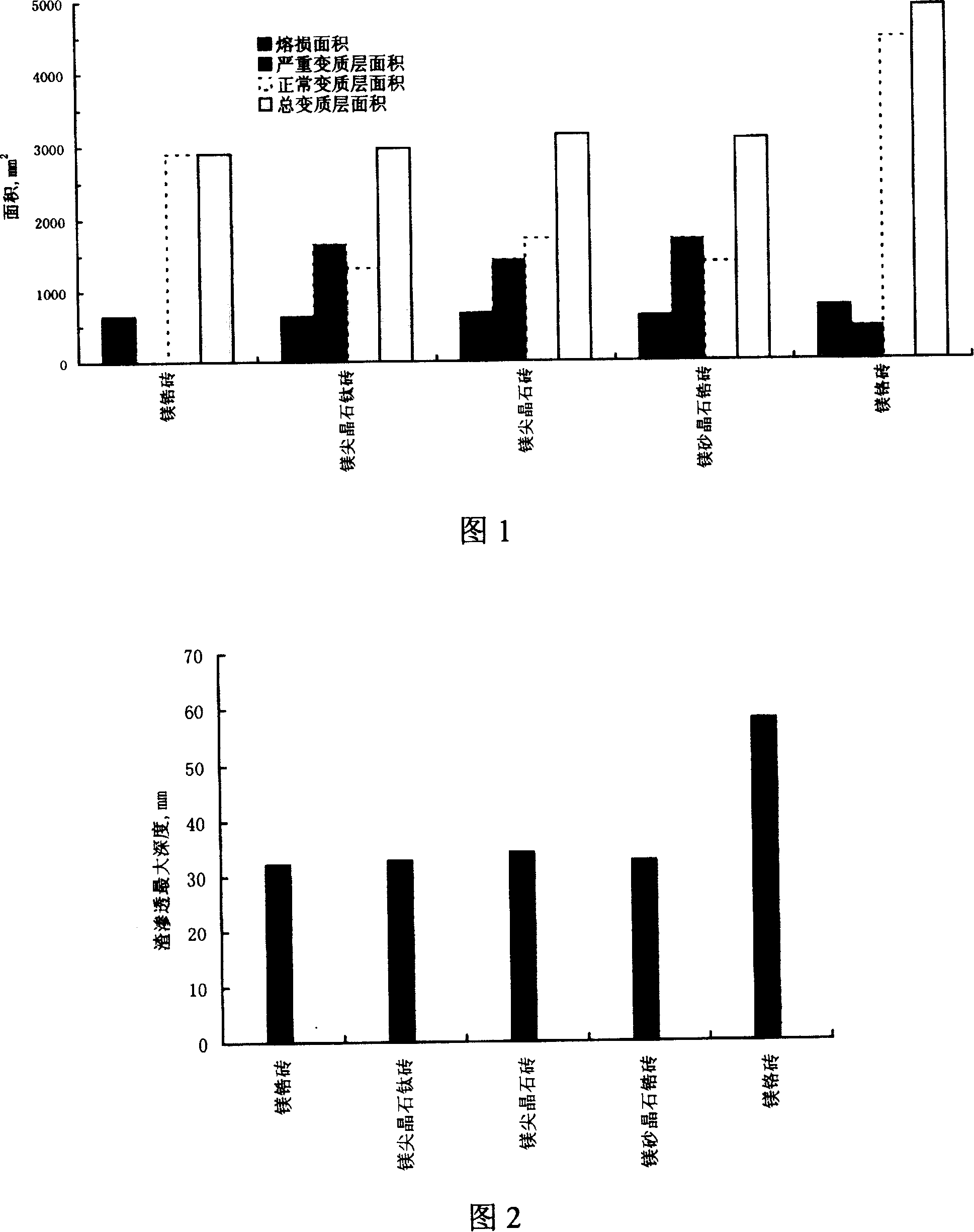

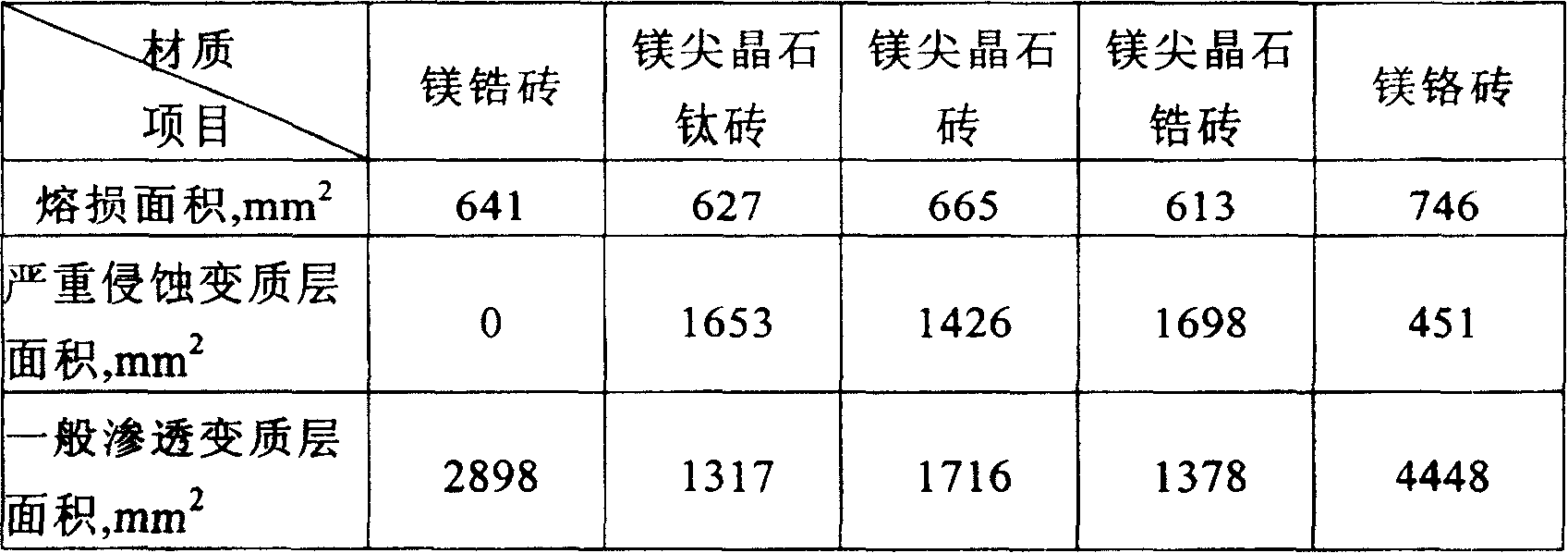

[0038] Examples are shown in Table 4.

[0039] Table 4

[0040] Example

comparative example

1

2

3

4

5

6

1

2

≤10mm

Electrofusion

Magnesia

91%

Electrofusion

Magnesia

88%

synthetic sand

96%

synthetic sand

92.5%

Electrofusion

Magnesia

91%

Magnesium zirconium

synthetic sand

94%

Magnesium zirconium

synthetic sand

96%

Electrofusion

Magnesia

84.5%

≤0.088mm

5%

8%

3%

4%

5%

15.5%

Zirconia

≤0.088mm

4%

4%

4%

4.5%

5%

1%

4%

sodium humate

(additional)

2%

2%

3%

2%

2%

2%

2%

2%

Body density g / cm 3

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com