High-air-permeability spherical ceramic particle sand for casting mold core and preparation method and application of high-air-permeability spherical ceramic particle sand

A technology of ceramic particles and casting molds, which is applied to casting molding equipment, cores, casting molds, etc., can solve the problems of large binder consumption, small thermal expansion coefficient, low heat resistance, etc., and achieve low batch use cost, Small coefficient of thermal expansion and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

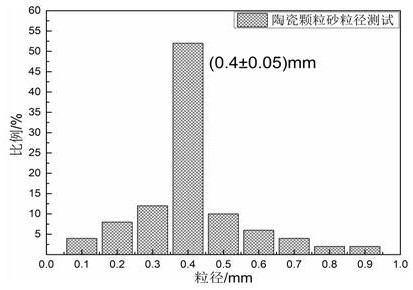

[0062] The present embodiment provides a high-permeability spherical ceramic particle sand for a casting core and a preparation method. The high-permeability spherical ceramic particle sand for a foundry core includes the following components in mass fractions: zirconia 6%, dioxide dioxide 7% silicon, 61% aluminum oxide, 7.5% magnesium oxide, 3% yttrium oxide, 3.5% modifier, 2.5% dispersant, and the balance is bentonite.

[0063] The bentonite consists of sodium bentonite, calcium bentonite and hydrogen bentonite, and the modifier consists of sodium tetraborate decahydrate, p-hydroxyacetophenone, calcium phosphate, sodium benzenesulfonate, diatomite, polyvinyl alcohol and mica powder The dispersant consists of sodium tripolyphosphate, sodium citrate and sodium metasilicate.

[0064] The particle size of zirconia is 2.5mm, the particle size of silica is 2.0mm, the particle size of aluminum oxide is 3.5mm, the particle size of magnesium oxide is 3.5mm, the particle size of yttri...

Embodiment 2

[0073] This embodiment provides a high-permeability spherical ceramic particle sand for a casting core and a preparation method, and the high-permeability spherical ceramic particle sand for a casting core includes the following components in the following mass fractions: zirconia 5.2%, dioxide dioxide Silicon 6.8%, aluminum oxide 60.6%, magnesium oxide 7.2%, yttrium oxide 2.8%, modifier 3.2%, dispersant 2.2%, and the balance is bentonite.

[0074] The bentonite consists of sodium bentonite, calcium bentonite and hydrogen bentonite, and the modifier consists of sodium tetraborate decahydrate, p-hydroxyacetophenone, calcium phosphate, sodium benzenesulfonate, diatomite, polyvinyl alcohol and mica powder The dispersant is composed of sodium tripolyphosphate, sodium citrate and sodium metasilicate.

[0075] The particle size of zirconia is 2.2mm, the particle size of silica is 1.5mm, the particle size of aluminum oxide is 3.0mm, the particle size of magnesium oxide is 3.2mm, the ...

Embodiment 3

[0085] A high-permeability spherical ceramic particle sand for casting cores and a preparation method, the high-permeability spherical ceramic particle sand for casting cores comprises the following components in mass fractions: zirconia 6.8%, silicon dioxide 7.6%, Aluminum oxide 61.6%, magnesium oxide 8.6%, yttrium oxide 3.7%, modifier 3.8%, dispersant 2.9%, and the balance is bentonite.

[0086] The bentonite consists of sodium bentonite, calcium bentonite and hydrogen bentonite, and the modifier consists of sodium tetraborate decahydrate, p-hydroxyacetophenone, calcium phosphate, sodium benzenesulfonate, diatomite, polyvinyl alcohol and mica powder The dispersant is composed of sodium tripolyphosphate, sodium citrate and sodium metasilicate.

[0087] The particle size of zirconia is 2.7mm, the particle size of silica is 2.8mm, the particle size of aluminum oxide is 4.5mm, the particle size of magnesium oxide is 4.8mm, the particle size of yttrium oxide is 3.6mm, and the par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com