Manufacturing method of antireflection film on outer surface of infrared optical window and optical lens

An infrared optical window and optical lens technology, applied in optics, optical components, instruments, etc., can solve the problem of corrosiveness of the film layer, and achieve the effect of strong corrosion resistance and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

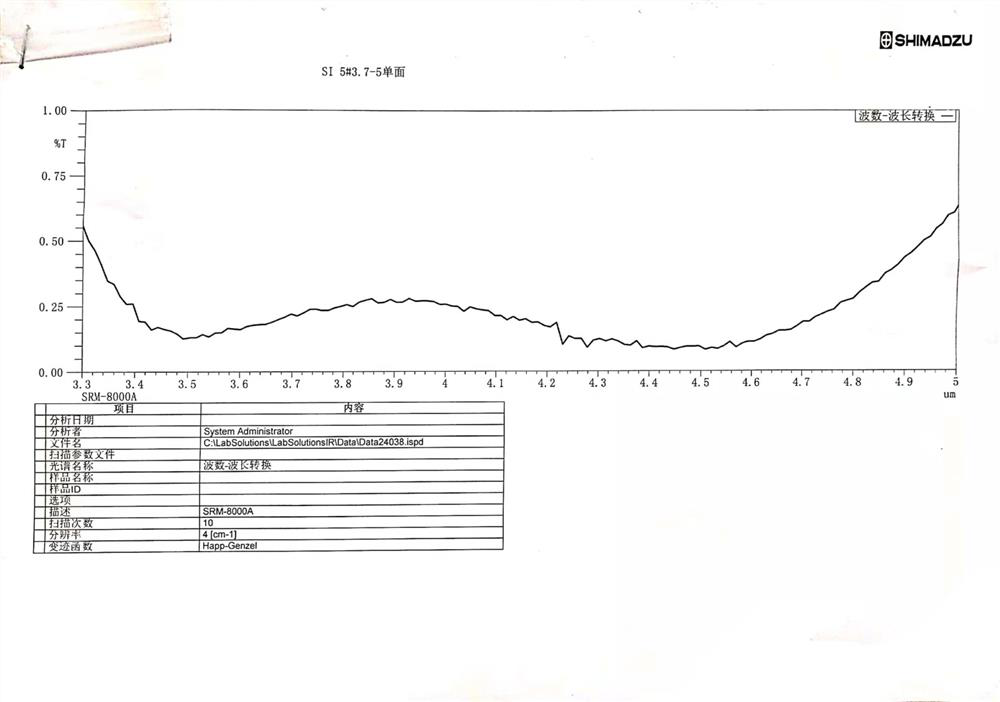

Image

Examples

Embodiment 1

[0020] The preparation method of the anti-reflection film on the outer surface of the infrared optical window and the optical lens specifically includes the following steps:

[0021] (1) Soak the anti-reflection coating substrate in gasoline and alcohol solution in turn for 4 hours. After soaking, wipe the parts with a mixture of alcohol and ether until the surface is clean; turn on the power of the coating machine, start the mechanical pump, and turn on the Pre-valve, close the pre-valve after pumping out the exhaust gas in the coating machine;

[0022] (2) Open the low valve and put the anti-reflection film substrate into the vacuum chamber of the coating machine to draw a low vacuum to 3.0E-3pa;

[0023] (3) Then apply a high vacuum to the anti-reflection film substrate. When it reaches 100Hz, close the low valve and open the pre-valve and high valve in turn, and restore the vacuum to 6.0E-3Pa;

[0024] (4) Heat the anti-reflection film substrate in the vacuum chamber, the...

Embodiment 2

[0029] The preparation method of the anti-reflection film on the outer surface of the infrared optical window and the optical lens specifically includes the following steps:

[0030] (1) Soak the anti-reflection coating substrate in gasoline and alcohol solution in turn for 6 hours. After soaking, wipe the parts with a mixture of alcohol and ether until the surface is clean; turn on the power of the coating machine, start the mechanical pump, and turn on the Pre-valve, close the pre-valve after pumping out the exhaust gas in the coating machine;

[0031] (2) Open the low valve and put the anti-reflection film substrate into the vacuum chamber of the coating machine to draw a low vacuum to 4.0E-3pa;

[0032] (3) Then apply a high vacuum to the anti-reflection film substrate. When it reaches 100Hz, close the low valve and open the pre-valve and high valve in turn, and restore the vacuum to 6.5E-3Pa;

[0033] (4) Heat the anti-reflection film substrate in the vacuum chamber, the...

Embodiment 3

[0038] The preparation method of the anti-reflection film on the outer surface of the infrared optical window and the optical lens specifically includes the following steps:

[0039] (1) Soak the anti-reflection coating substrate in gasoline and alcohol solution in turn for 5 hours. After soaking, wipe the parts with a mixture of alcohol and ether until the surface is clean; turn on the power of the coating machine, start the mechanical pump, and turn on Pre-valve, close the pre-valve after pumping out the exhaust gas in the coating machine;

[0040] (2) Open the low valve and put the anti-reflection film substrate into the vacuum chamber of the coating machine to draw a low vacuum to 4.0E-3pa;

[0041] (3) Then apply a high vacuum to the anti-reflection film substrate. When it reaches 100Hz, close the low valve and open the pre-valve and high valve in turn, and restore the vacuum to 6.5E-3Pa;

[0042] (4) Heat the anti-reflection film substrate in the vacuum chamber, the hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com