Anti-corrosion photo album and production process thereof

A production process and anti-corrosion technology, applied in anti-corrosion coatings, atlases, coatings, etc., can solve problems such as photo damage, poor anti-corrosion performance, and easy corrosion damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

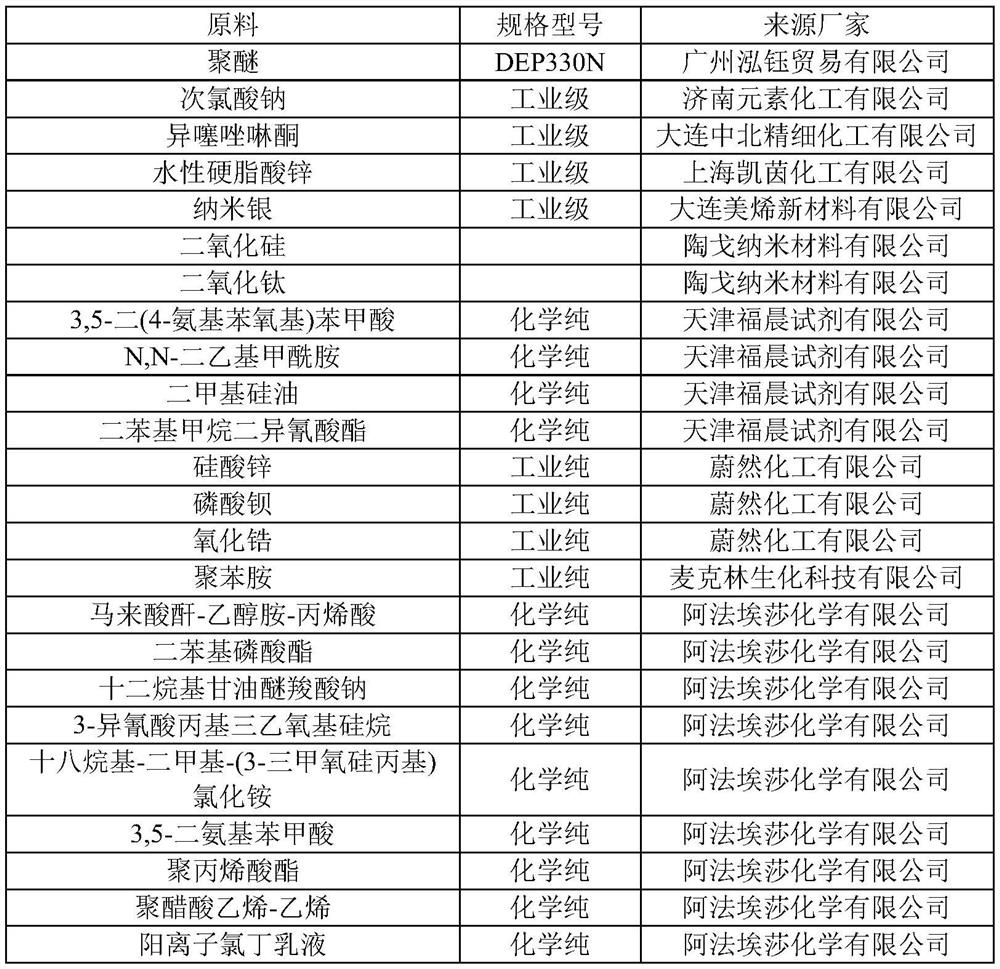

[0060] The anti-corrosion photo album of this embodiment comprises a photo album cover and a photo album inner page. The photo album cover and the photo album inner page are made of hard cardboard. The surface of the photo album cover and the photo album inner page is coated with an anti-corrosion layer. Raw materials: 30g of binder, 15g of filler, 3g of coupling agent, and 0.5g of defoamer.

[0061] Wherein, the binder is composed of cyanoacrylate and chitosan in a mass ratio of 2:3.5. The filler is composed of zinc silicate, titanium dioxide, barium phosphate, zirconia and silicon dioxide in a mass ratio of 1:2:1:1:1. The coupling agent is composed of 3-isocyanatopropyltriethoxysilane and octadecyl-dimethyl-(3-trimethoxysilylpropyl)ammonium chloride in a mass ratio of 2:0.8. The defoamer is composed of simethicone and polyether in a mass ratio of 4:2.5.

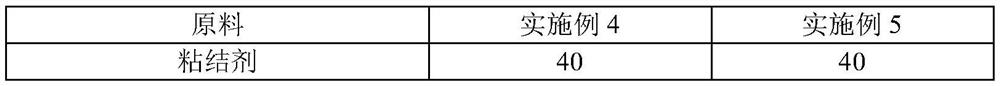

[0062] The addition (g) of raw material among the embodiment 2-3 is as shown in table 2, and all the other are identica...

Embodiment 4

[0072] The anti-corrosion photo album of this embodiment comprises a photo album cover and a photo album inner page. The photo album cover and the photo album inner page are made of hard cardboard. The surface of the photo album cover and the photo album inner page is coated with an anti-corrosion layer. Raw materials: 30g of binder, 15g of filler, 3g of coupling agent, and 0.5g of defoamer.

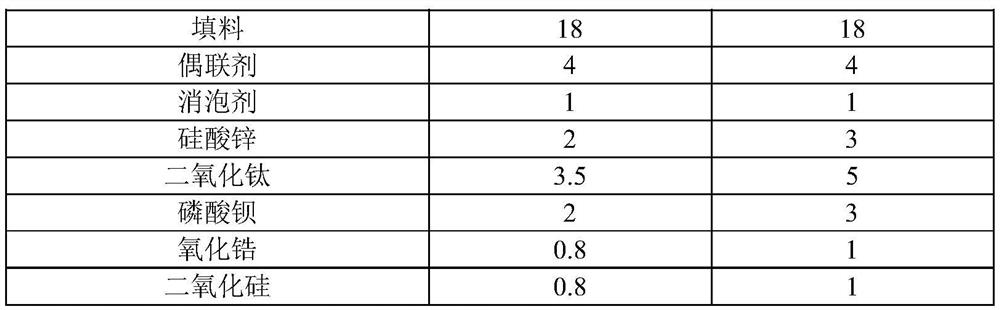

[0073] Wherein, the binder is composed of cyanoacrylate and chitosan in a mass ratio of 2:3.5. The fillers are zinc silicate, titanium dioxide, barium phosphate, zirconia and silicon dioxide. The coupling agent is composed of 3-isocyanatopropyltriethoxysilane and octadecyl-dimethyl-(3-trimethoxysilylpropyl)ammonium chloride in a mass ratio of 2:0.8. The defoamer is composed of simethicone and polyether in a mass ratio of 4:2.5. Titanium dioxide is nano titanium dioxide. Nano-silica is fumed nano-silica.

Embodiment 5

[0074] The addition (g) of zinc silicate, titanium dioxide, barium phosphate, zirconium oxide, silicon dioxide in the raw material of embodiment 5 is as shown in table 3, and all the other are identical with embodiment 4.

[0075] The addition amount of zinc silicate, titanium dioxide, barium phosphate, zirconium oxide, silicon dioxide in the raw material of table 3 embodiment 4-5

[0076]

[0077]

[0078] The production process of the anti-corrosion photo album of embodiment 4-5 is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com