A kind of preparation method of zirconia-silicon dioxide composite adsorption material

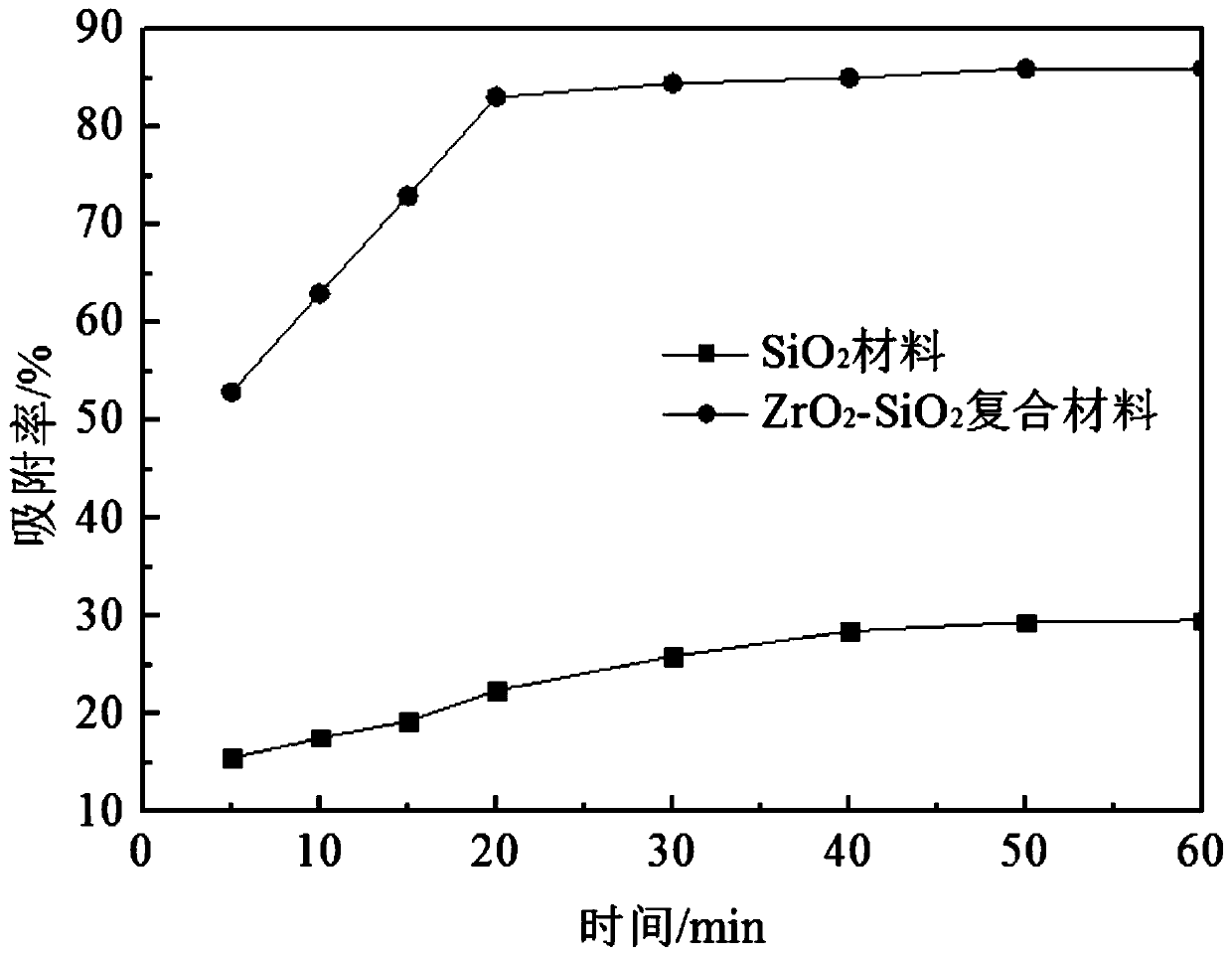

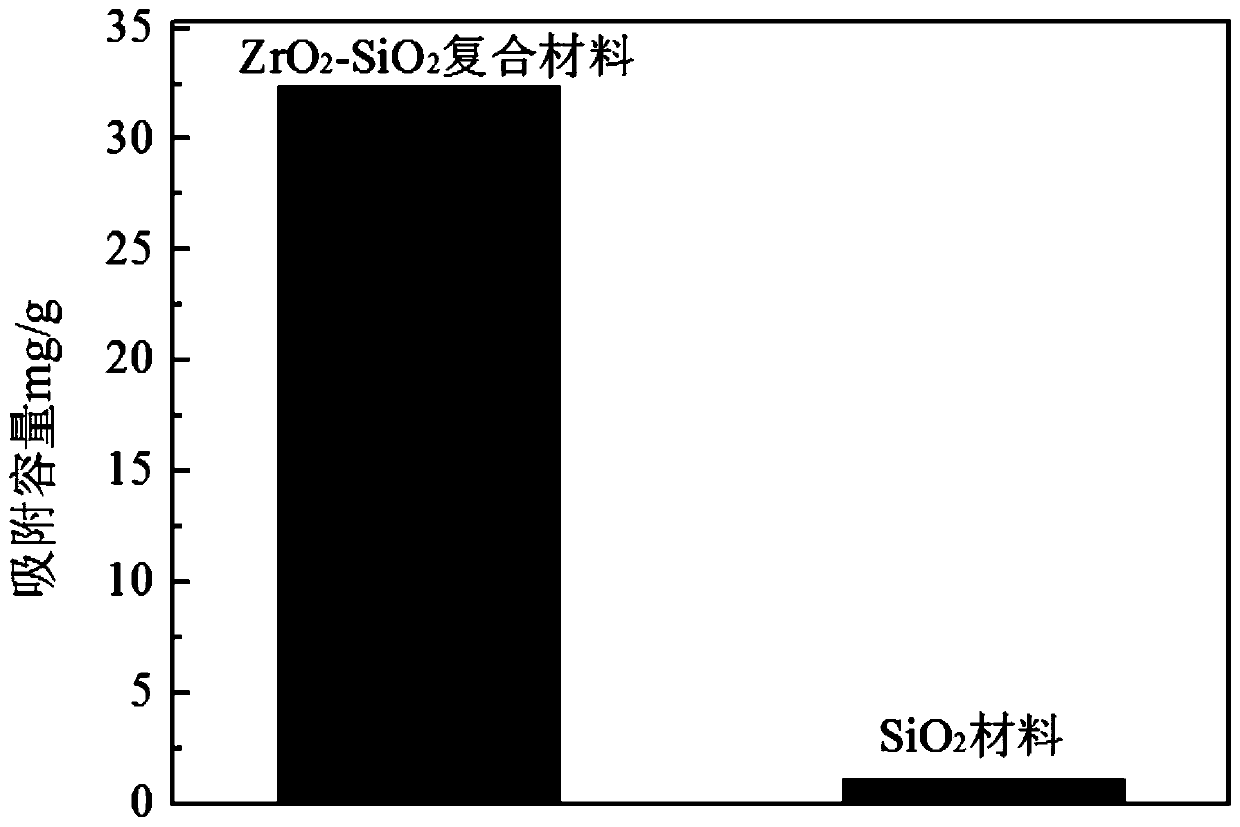

A composite adsorption material, silica technology, applied in chemical instruments and methods, silicon compounds, adsorbed water/sewage treatment, etc., can solve the problems of slow adsorption rate, low adsorption rate, etc., to improve the adsorption rate and improve the adsorption rate. , the effect of the simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A kind of preparation method of zirconium dioxide-silicon dioxide composite adsorption material of the present invention comprises the following steps:

[0026] Step 1, prepare SiO 2 sol

[0027] Take an appropriate amount of tetraethyl orthosilicate and anhydrous ethanol and fully mix it into a homogeneous solution, place it in an ice-water mixture, stir the homogeneous solution while slowly adding water and HCl or HNO 3 The mixture is stirred and refluxed at a temperature of 50-75°C for 2-5h and then cooled to room temperature to obtain SiO 2 Sol, ready for use, in which tetraethyl orthosilicate (TEOS), absolute ethanol (EtOH), water, HCl or HNO 3 The molar ratio is 1.0: 3.0-9.0:3.0-8.0:0.04-0.12, HCl or HNO 3 The concentration is 1.0-2.0mol / L;

[0028] Step 2, prepare ZrO 2 sol

[0029] Take the oxalic acid solution and the zirconium nitrate pentahydrate solution with a molar ratio of 1:4-5, add the oxalic acid solution dropwise to the zirconium nitrate pentahy...

Embodiment 1

[0034] (1) Preparation of SiO 2 sol

[0035] Thoroughly mix ethyl orthosilicate and absolute ethanol to form a homogeneous solution, put it in the ice-water mixture, add water and HCl with a concentration of 1.0mol / L while stirring, and stir and reflux at a temperature of 50°C for 5 hours Cool to room temperature to get SiO 2 Sol; wherein the molar ratio of ethyl orthosilicate, absolute ethanol, water, and HCl is 1:3:3:0.04.

[0036] (2) Preparation of ZrO 2 sol

[0037] Take zirconium nitrate pentahydrate solution and oxalic acid with a molar ratio of 4.5:1, add 0.2mol / L oxalic acid solution dropwise into 0.6mol / L zirconium nitrate pentahydrate solution, stir rapidly and heat to 50°C, keep the temperature and Add glycerol dropwise, stir and reflux for 4h and cool to room temperature to obtain clear and transparent ZrO 2 Sol, wherein the volume of glycerol is 30% of the sum of the volumes of zirconium nitrate pentahydrate solution and oxalic acid solution.

[0038] (3) Pre...

Embodiment 2

[0042] (1) Preparation of SiO 2 sol

[0043] Thoroughly mix tetraethyl orthosilicate and absolute ethanol to form a homogeneous solution, place it in ice-water mixture, add water and HCl with a concentration of 1.5mol / L while stirring, and stir and reflux at a temperature of 65°C for 3 hours Cool to get SiO 2 Sol; wherein the molar ratio of ethyl orthosilicate, absolute ethanol, water, and HCl is 1:8.3:7.6:0.1.

[0044] (2) Preparation of ZrO 2 sol

[0045] Take zirconium nitrate pentahydrate solution and oxalic acid with a molar ratio of 4:1, add 0.15mol / L oxalic acid solution dropwise into 0.4mol / L zirconium nitrate pentahydrate solution, stir rapidly and heat to 60°C, keep the temperature and Add glycerol dropwise, stir and reflux for 3h and cool to room temperature to obtain clear and transparent ZrO 2 Sol, wherein the volume of glycerol is 20% of the sum of the volumes of zirconium nitrate pentahydrate solution and oxalic acid solution.

[0046] (3) Preparation of Z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com