A kind of high frequency, wide temperature and low loss soft ferrite material and preparation method thereof

A soft magnetic ferrite, low loss technology, applied in the magnetic direction of inorganic materials, can solve problems such as unsatisfactory use requirements and increased core loss, and achieve the effects of grain refinement, loss reduction, and eddy current loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

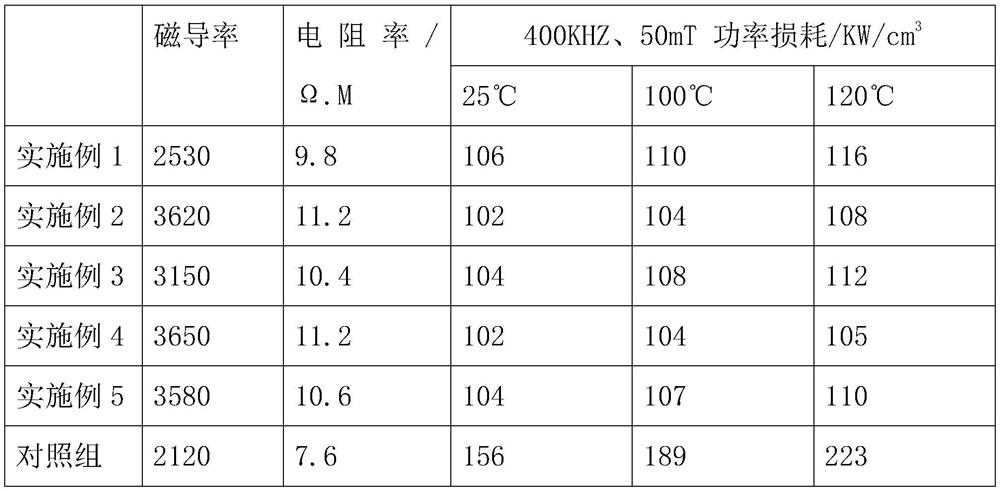

Examples

Embodiment 1

[0029] The invention provides a high-frequency, wide-temperature, low-loss soft ferrite material, which includes a main material component and an auxiliary material component. The main material components include 52.4 mol% of ferric oxide, 9.3 mol% of zinc oxide, and the rest are oxidized manganese;

[0030] The auxiliary ingredients include calcium carbonate, cobalt trioxide, niobium pentoxide, titanium dioxide, zirconium dioxide, silicon dioxide, copper oxide, tantalum pentoxide and diboron trioxide.

[0031]In a preferred embodiment, based on the total weight of the main ingredients, the auxiliary ingredients include the following contents: calcium carbonate 0.02wt%, cobalt trioxide 0.3wt%, niobium pentoxide 0.03wt%, titanium dioxide 0.05wt% %, zirconium dioxide 0.001wt%, silicon dioxide 0.001wt%, copper oxide 0.05wt%, tantalum pentoxide 0.06wt%, diboron trioxide 0.05wt%.

[0032] The invention also provides a preparation method of a high-frequency, wide-temperature and lo...

Embodiment 2

[0045] Different from embodiment 1, the molar percentage content of the main ingredient is ferric oxide 53mol%, zinc oxide 9.5mol%, and the rest are manganese oxide;

[0046] Based on the total weight of the main ingredients, the auxiliary ingredients include the following percentages: calcium carbonate 0.04wt%, cobalt trioxide 0.35wt%, niobium pentoxide 0.04wt%, titanium dioxide 0.1wt%, zirconium dioxide 0.008 wt %, silicon dioxide 0.0045 wt %, copper oxide 0.1 wt %, tantalum pentoxide 0.08 wt %, diboron trioxide 0.1 wt %.

[0047] In a preferred embodiment, the obtained high-frequency, wide-temperature and low-loss soft ferrite material has a magnetic permeability of 3620 at room temperature. Magnetic loss is 108KW / cm 3 .

Embodiment 3

[0049] What is different from embodiment 1-2 is that the molar percentage content of the main ingredients is ferric oxide 53.5mol%, zinc oxide 9.7mol%, and the rest are manganese oxide;

[0050] Based on the total weight of the main ingredients, the following percentages of auxiliary ingredients: calcium carbonate 0.06wt%, cobalt trioxide 0.4wt%, niobium pentoxide 0.05wt%, titanium dioxide 0.15wt%, zirconium dioxide 0.015wt%, Silicon dioxide 0.008wt%, copper oxide 0.15wt%, tantalum pentoxide 0.1wt%, diboron trioxide 0.15wt%.

[0051] In a preferred embodiment, the obtained high-frequency, wide-temperature and low-loss soft ferrite material has a magnetic permeability of 3150 at room temperature. Magnetic loss is 112KW / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| magnetic loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com