Sensor for measuring content of hydrogen in metal melt and measuring method

A metal melt and sensor technology, applied in the field of hydrogen measurement sensing, can solve the problems of reducing the response speed, easily blocking the gas chamber, affecting the measurement accuracy, etc., and achieves the effect of simplified and simple method, more intuitive method, and fast measurement speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

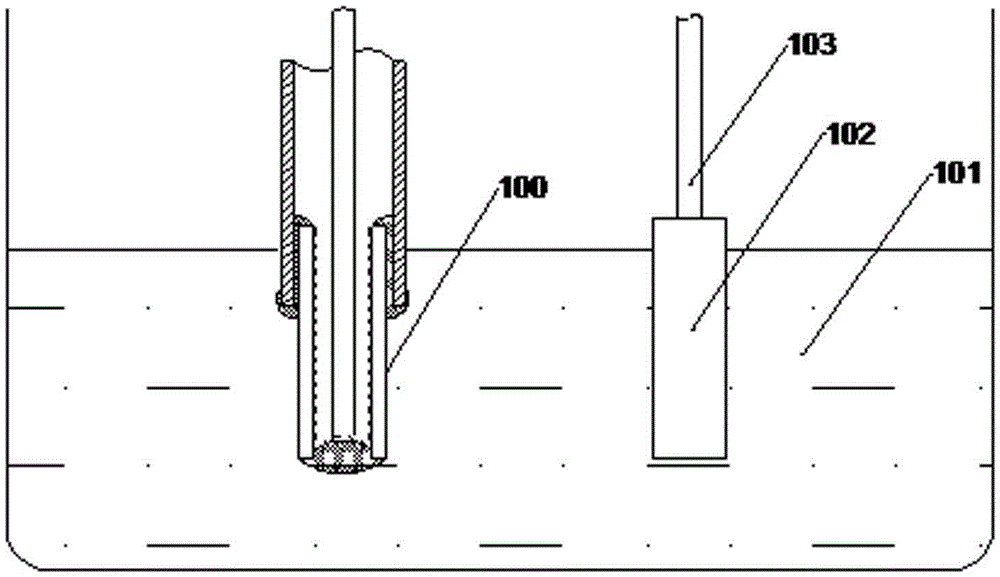

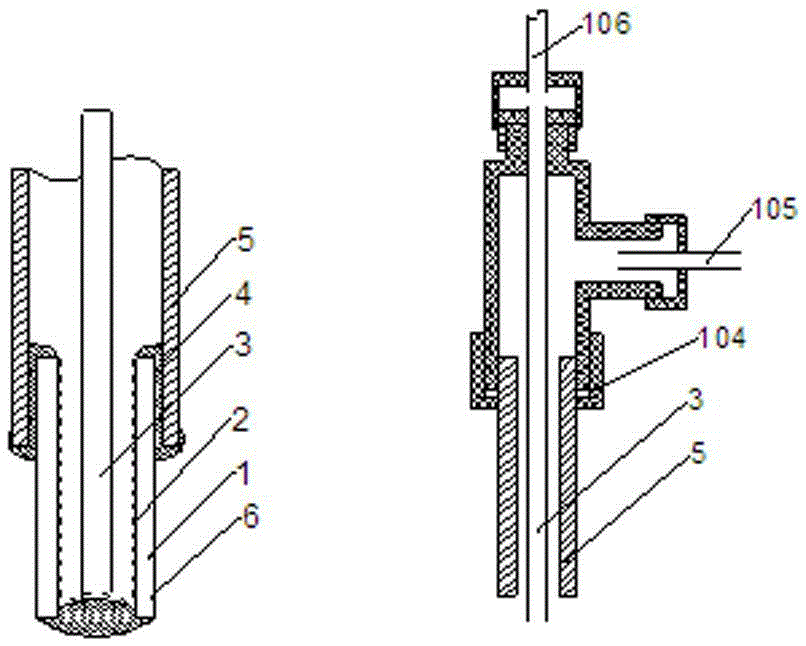

[0067] Sensors for measuring the hydrogen content in aluminum melts, e.g. figure 1 and figure 2 shown, including CaZr 0.9 In 0.1 o 3-α Solid proton conductor element 1, reference porous electrode 2, quasi-test electrode 6, reference substance Ar-H 2 , stainless steel air guide tube 3, corundum through tube 5, alumina-based insulating ceramic binder 4 and polytetrafluoroethylene tee fixture 104; wherein the solid proton conductor element 1 is a tube structure, the material is perovskite, and one end is made of Alumina-based ceramic adhesive 4 is sealed, and the through pipe 5 and the solid proton conductor element 1 are connected through the insulating ceramic adhesive 4 to form an inner space. The surface of the solid proton conductor element 1 located in the space is the inner surface, exposed The outer surface is the outer surface; the reference porous electrode 2 is coated on the inner surface of the solid proton conductor element 1 and the alumina-based ceramic binde...

Embodiment 2

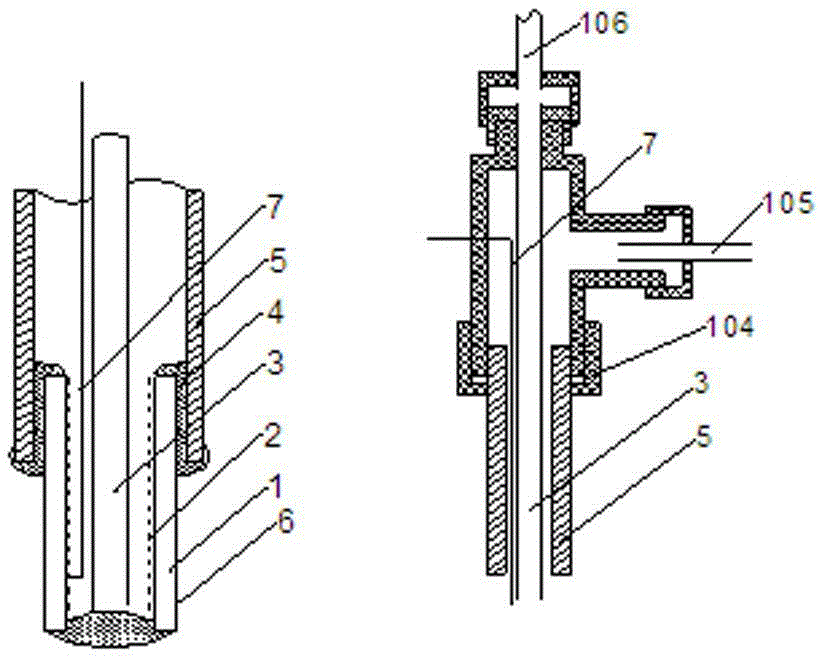

[0080] The sensor that measures the hydrogen content in the aluminum melt is the same as embodiment 1, such as image 3 As shown, the difference is that the sensor structure also includes a reference electrode wire 7, the material is metal platinum, which is inserted into the quartz through tube 5 through the copper three-way fixture 104, connected with the gold reference porous electrode 2, and connected externally to the Measuring circuit; the material of the air guide tube is corundum; the material of the solid proton conductor element 1 is CaZr 0.9 sc 0.1 o 3-α ; Tee clamp 104 is made of copper; the material of the through pipe is quartz; the reference porous electrode is made of porous gold.

[0081] The method of using the sensor to measure the hydrogen content in the metal melt is carried out according to the following process steps: ① Insert the sensor and the graphite corrosion-resistant electrode into the aluminum melt at 750°C, and ensure that the solid proton con...

Embodiment 3

[0083] The sensor that measures the hydrogen content in the aluminum melt is the same as embodiment 1, such as Figure 4 As shown, the difference is that: the solid proton conductor element 1 used in the sensor structure is a sheet structure; the material of the through pipe 5 is stainless steel; As the gas outlet, the vertical distance between the gas outlet and the uppermost end of the solid proton conductor is 2~5mm; the material of the gas guide tube is nickel-chromium alloy; the reference gas is He-H 2 , the molar hydrogen content is 1.00%.

[0084] The method for measuring the hydrogen content in the molten metal with the sensor is carried out according to the following process steps: ① insert the sensor and the graphite corrosion-resistant electrode into the molten aluminum at 750°C, and ensure that the solid-state proton conductor element is completely submerged in the molten metal , the electrode to be tested is in direct contact with the metal melt, and the contact ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| activity coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com