A proton exchange film for direct carbinol fuel battery and its making method

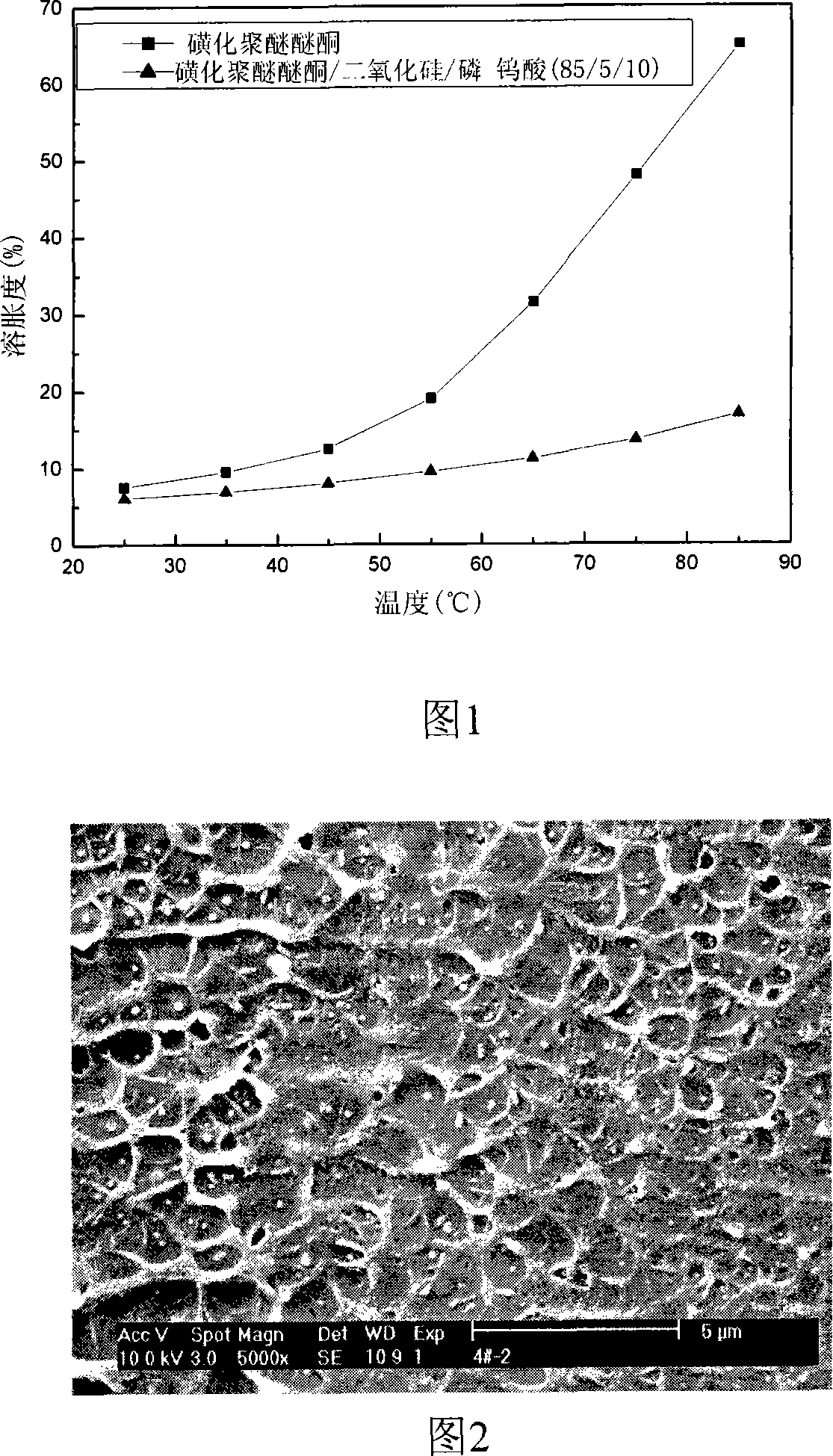

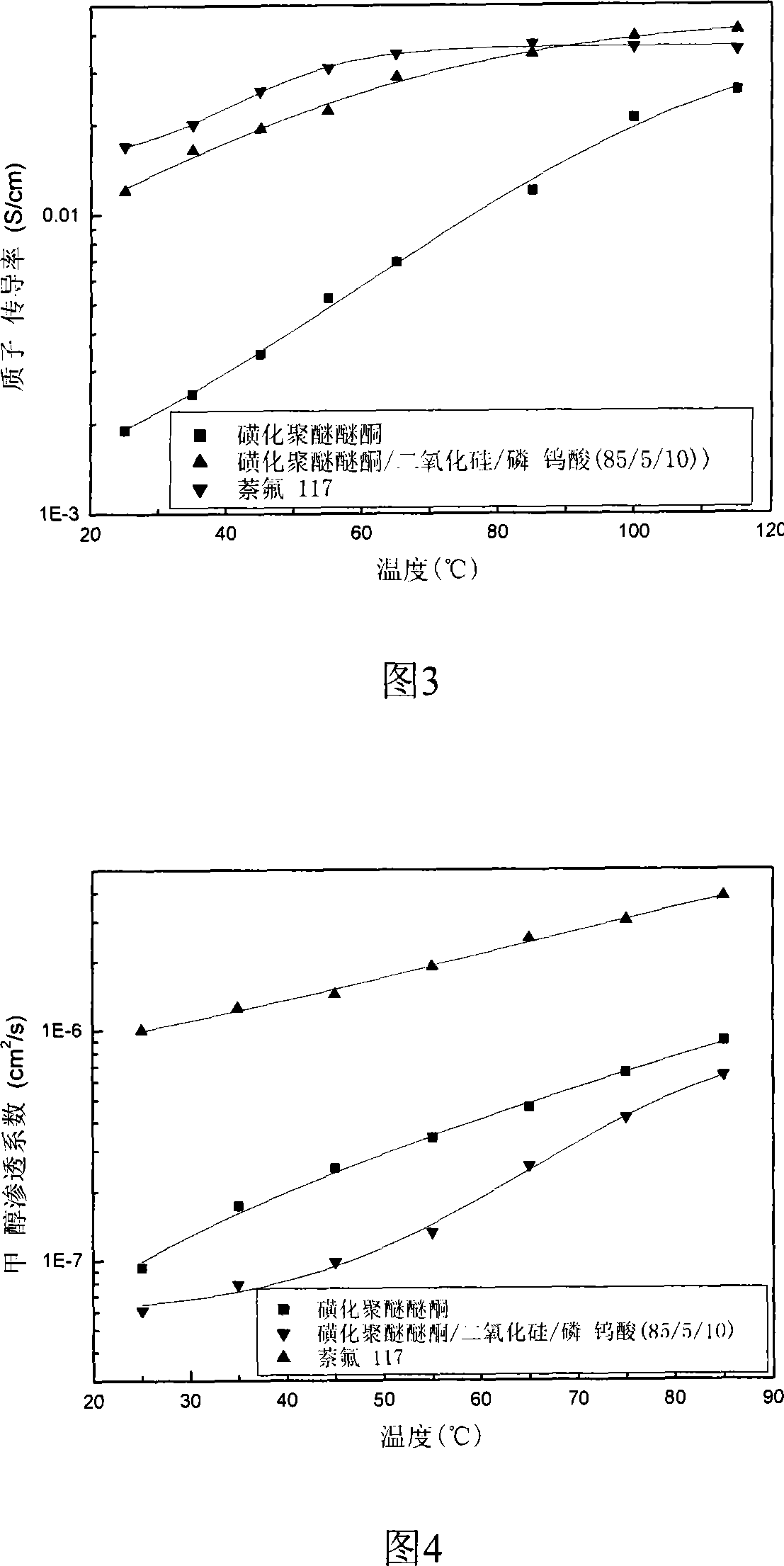

A technology of methanol fuel cell and proton exchange membrane, which is applied in the direction of fuel cell, fuel cell parts, solid electrolyte fuel cell, etc., and can solve the problem that the composite SPEEK proton exchange membrane preparation process and comprehensive performance are not perfect enough to reach DMFC Use requirements, membrane proton conduction performance decline and other issues, to achieve the effect of reducing methanol permeability, improving proton conduction performance, increasing power density and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Dissolve 3 grams of polyether ether ketone (PEEK) pellets in 180 grams of concentrated sulfuric acid with a concentration of 98% by weight, stir vigorously at 30°C, and after sulfonation continues for 48 hours, pour the reaction solution into ice Dilute it in water so that the volume of ice water is 5 times that of the reaction solution, filter the diluted reaction solution to get the precipitate, wash the precipitate repeatedly with distilled water until the aqueous solution is neutral, and then dry it in vacuum at 60°C for 24 hours to obtain the sulfonated polymer. Ether ether ketone (SPEEK);

[0038] (2) Dissolve 3 grams of SPEEK in 27 grams of anhydrous N,N-dimethylacetamide (DMAc) to form a 10 wt.% solution. Then add 0.26 g of N, N'-carbonyldiimidazole (CDI), the added CDI and SPEEK on -SO 3 The molar ratio of H was 1:4, and the reaction was stirred at 60°C for 2 hours. Then add 0.35 g of aminopropyltriethoxysilane (AS), the molar ratio of the added AS to CDI...

Embodiment 2

[0045] (1) Dissolve 6 grams of polyether ether ketone pellets in 300 grams of concentrated sulfuric acid with a concentration of 98% by weight, stir vigorously at 60° C., and continue sulfonation for 12 hours, then pour the reactants into ice water to dilute, Make the volume of ice water 6 times that of the reaction solution, filter the diluted reaction solution to take the precipitate, wash the precipitate repeatedly with distilled water until the aqueous solution is neutral, and then dry it in vacuum at 60°C for 24 hours to obtain sulfonated polyether ether ketone ( SPEEK);

[0046] (2) Dissolve 6 grams of SPEEK in 44 grams of anhydrous N,N-dimethylpyrrolidone (NMP) to form a 12 wt.% solution. Then add 0.57 g of N, N'-carbonyldiimidazole (CDI), make CDI and SPEEK on -SO 3 The molar ratio of H was 1:3.5, and the reaction was stirred at 60°C for 1 hour. Then add 0.91 g of γ-(2,3-cyclopropoxy)propyltrimethoxysilane (GPTS), the molar ratio of GPTS to CDI is 1:1, and stir and r...

Embodiment 3

[0052] (1) Dissolve 4 grams of polyether ether ketone pellets in 160 grams of concentrated sulfuric acid with a concentration of 98% by weight, stir vigorously at 50°C, and continue sulfonation for 18 hours, then pour the reactants into ice water to dilute, Make the volume of ice water 8 times that of the reaction solution, filter the diluted reaction solution to get the precipitate, wash the precipitate repeatedly with distilled water until the aqueous solution is neutral, and then dry it in vacuum at 60°C for 24 hours to obtain sulfonated polyether ether ketone ( SPEEK);

[0053] (2) Dissolve 4g of SPEEK in 22.7g of anhydrous N,N-dimethylformamide (DMF) to form a 15wt.% solution. Then add 0.54 g of N, N'-carbonyldiimidazole (CDI), CDI and SPEEK on -SO 3 The molar ratio of H was 1:2.5, and the reaction was stirred at 60°C for 2.5 hours. Then add 0.74 g of γ-aminopropyltriethoxysilane, the molar ratio of γ-aminopropyltriethoxysilane to CDI is 1:1, and stir and react at 60°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Proton conductivity | aaaaa | aaaaa |

| Methanol permeability coefficient | aaaaa | aaaaa |

| Proton conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com