Organic-inorganic composite proton exchange membrane for proton exchange membrane fuel cell and preparation method thereof

A proton exchange membrane and inorganic composite technology, applied in solid electrolyte fuel cells, fuel cell components, final product manufacturing, etc., can solve problems such as battery performance attenuation, conductivity drop, loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 1 weight unit of polyphenylsulfone (PPSF) and 1 weight unit of polyvinylpyrrolidone (PVP), dissolve them in 18 weight units of N,N-dimethylformamide (DMF), and stir until completely dissolved;

[0027] Weigh 1 weight unit of phosphotungstic acid, dissolve it in 9 weight units of N,N-dimethylformamide (DMF), and stir until completely dissolved;

[0028] Mix the above two solutions together and stir evenly. After degassing the polymer solution, cast it on a clean and flat solid surface (such as a glass plate) and dry the volatile solvent at 50°C to form a film.

[0029] The obtained organic-inorganic composite proton exchange membrane has high mechanical properties and good flexibility. The mechanical performance test adopts the national standard GB13022-91 for measurement, the instrument used is CMT6202, the tensile strength is 35MPa, and the elongation at break reaches 40%.

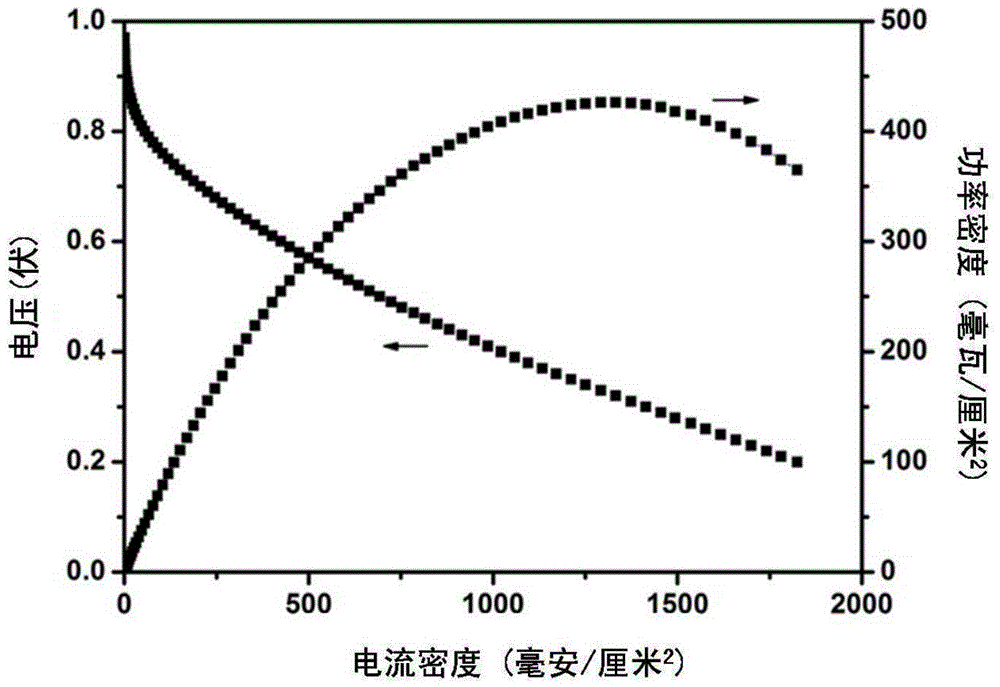

[0030] The obtained organic-inorganic composite proton exchange membrane has good proton...

Embodiment 2

[0032] Weigh 1 weight unit of polysulfone (PSF) and 1.5 weight units of polyvinylpyrrolidone (PVP), dissolve them in 10 weight units of N,N-dimethylacetamide (DMAc), and stir until completely dissolved;

[0033] Weigh 1.5 weight units of phosphotungstic acid, dissolve it in 8.5 weight units of N,N-dimethylformamide (DMF), and stir until completely dissolved;

[0034] The above two polymer solutions were mixed together and stirred evenly, the polymer solution was degassed, and then the volatile solvent was dried at 60° C. by casting method to form a film.

[0035] The obtained organic-inorganic composite proton exchange membrane has high mechanical properties and good flexibility. The mechanical performance test is measured by the national standard GB13022-91, the instrument used is CMT6202, the tensile strength is 32MPa, and the elongation at break reaches 50%.

[0036] The obtained organic-inorganic composite proton exchange membrane has good proton conductivity, and the con...

Embodiment 3

[0038] Weigh 1 weight unit of polyethersulfone (PES) and 2 weight units of polyvinylpyrrolidone (PVP), dissolve them in 11 weight units of N-methylpyrrolidone (NMP), stir until completely dissolved; mix the above two The polymer solutions were mixed together and stirred evenly,

[0039] Weigh 2 weight units of phosphotungstic acid, dissolve it in 8 weight units of N,N-dimethylformamide (DMF), and stir until completely dissolved;

[0040] The above two polymer solutions were mixed together and stirred evenly, the polymer solution was degassed, and the volatile solvent was dried at 70° C. by casting method to form a film.

[0041] The obtained organic-inorganic composite proton exchange membrane has high mechanical properties and good flexibility. The mechanical performance test is measured by the national standard GB13022-91, the instrument used is CMT6202, the tensile strength is 28MPa, and the elongation at break reaches 58%.

[0042]The obtained organic-inorganic composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com