Flexible microgyrorotor and electromagnetic drive and dynamic tune

A technology of dynamic tuning and flexible rotor, applied in the field of micro gyroscope, which can solve the problems of complex overall structure, large size and increased weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

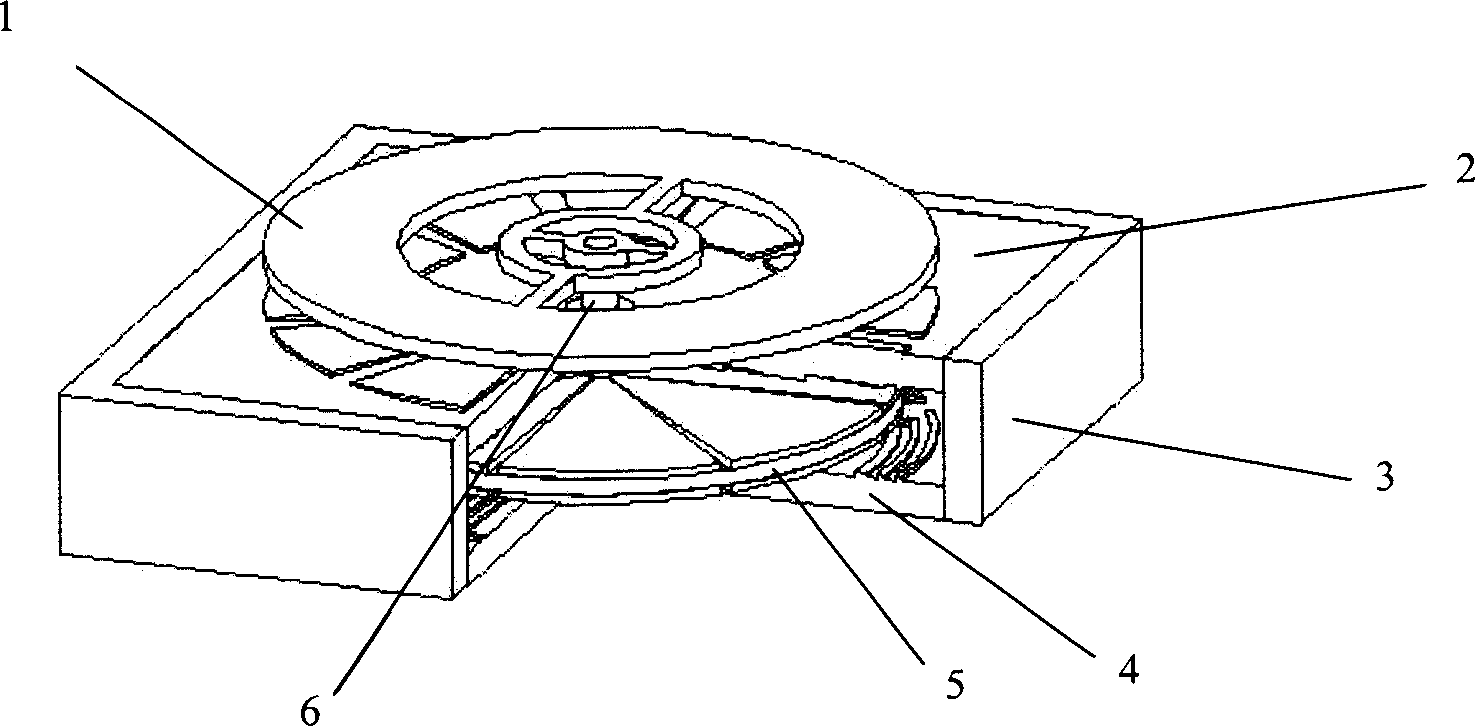

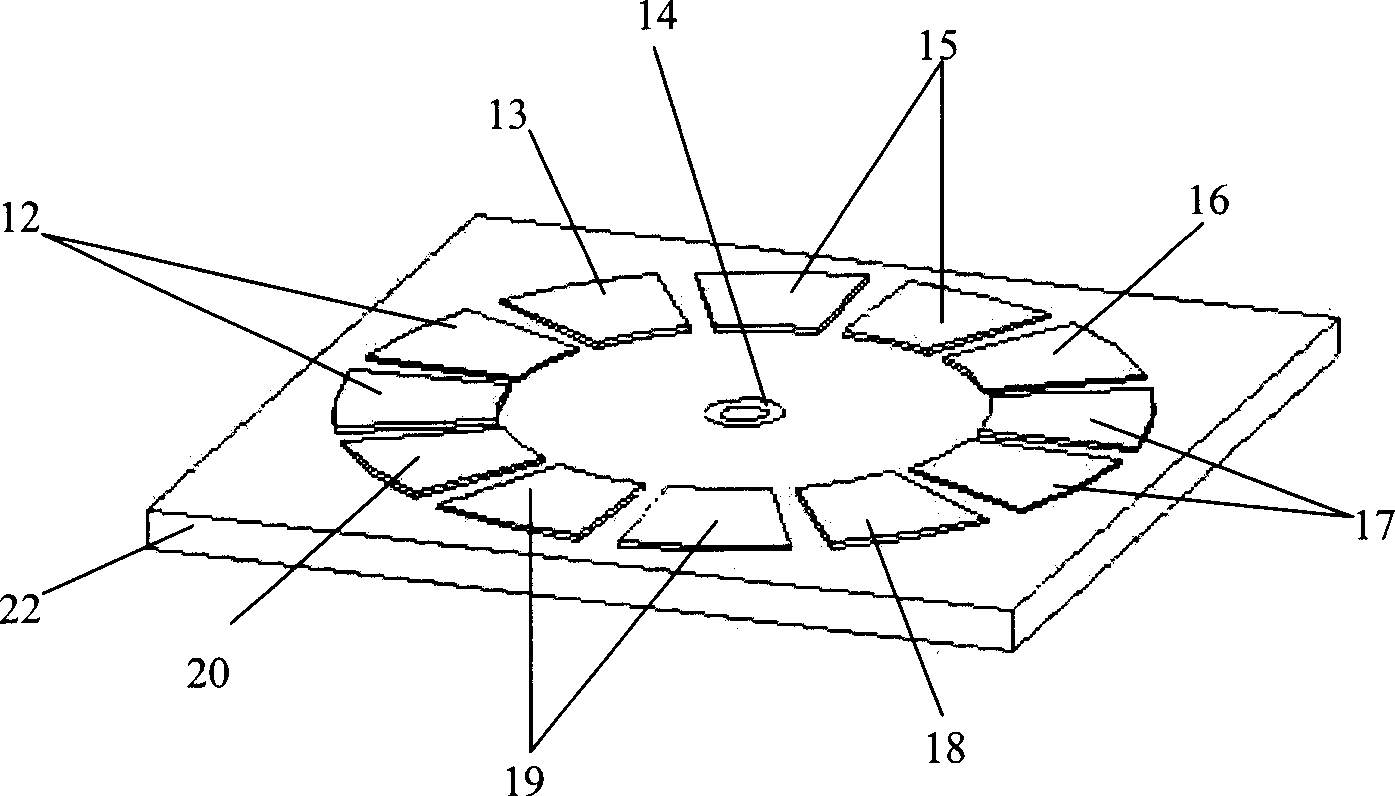

[0020] like figure 1 , image 3 , Figure 4 , Figure 5 As shown, the present invention includes: gyro rotor 1, upper stator 2, housing 3, lower stator 4, drive rotor 5, shaft 6, jewel bearing 14, jewel bearing 23. The connection relationship is as follows: the upper stator 2 and the lower stator 4 are arranged on the upper and lower parts of the housing 3, the jewel bearing 14 is arranged at the center hole of the upper stator 2, the jewel bearing 23 is arranged at the center hole of the lower stator 4, and the shaft 6 Set on the jewel bearing 14 and the jewel bearing 23, the drive rotor 5 is set on the shaft 6, and the drive rotor 5 is located between the upper stator 2 and the lower stator 4, the gyro rotor 1 is set on the shaft 6, and is located between the upper stator 1 superior.

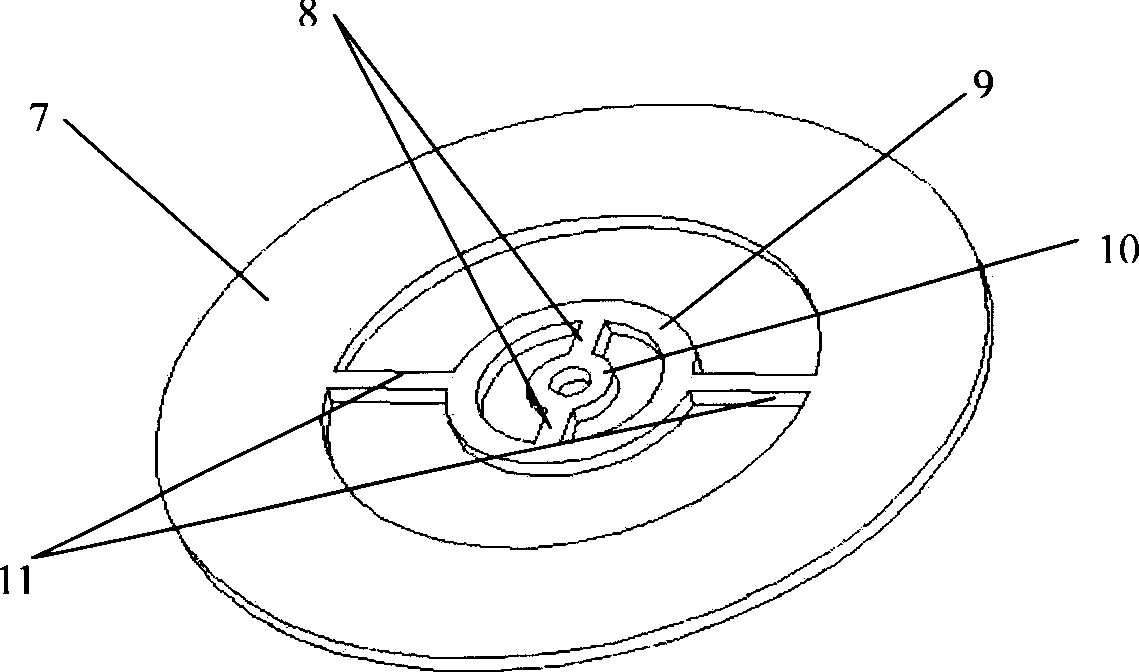

[0021] like figure 2 As shown, the gyro rotor 1 of the present invention includes: an outer ring 7 , an outer connecting beam 11 , an inner ring 9 , an inner connecting beam 8 , and a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com