Sandwich type acoustic window structure of ship dome

A technology of deflector and sound-transmitting window, which is applied in ship construction, ship parts, ships, etc., can solve the problems of poor flow noise performance, reduce vibration, improve stability, and reduce signal interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

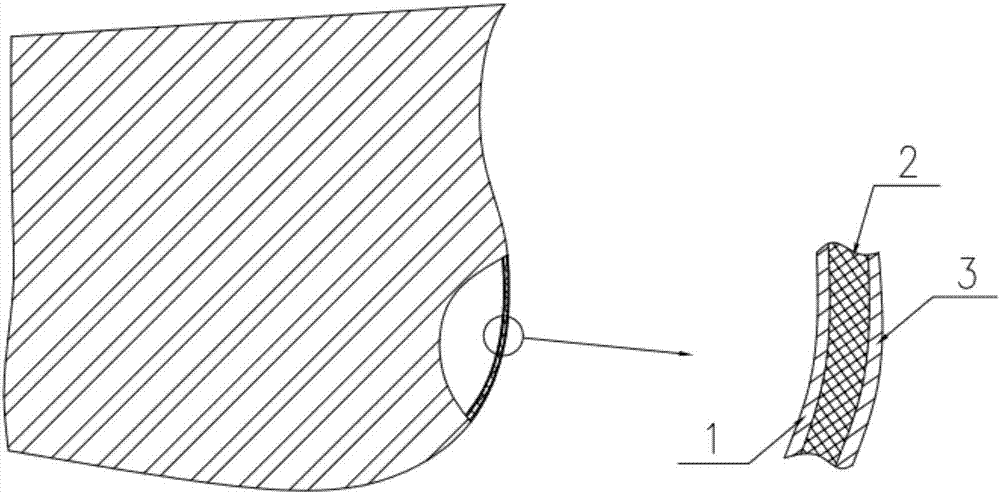

[0017] A sandwich sound-permeable window structure for a ship's windshield, the sandwich-type sound-permeable window structure for a ship's windshield includes an inner constraining surface layer 1, an outer constraining surface layer 3, and a core layer 2, and the core layer 2 is tightly Bonded between the inner constraining surface layer 1 and the outer constraining surface layer 3; the inner constraining surface layer 1 and the outer constraining surface layer 3 are both made of fiber-reinforced resin-based composite materials, and the core layer 2 is made of viscoelastic material become.

[0018] Wherein, the inner constraining surface layer 1 and the outer constraining surface layer 3 are made of carbon fiber reinforced composite material; the core layer 2 is made of polyurethane viscoelastic material. The thickness of the outer constraining surface layer 3 is 0.2mm; the thickness of the inner constraining surface layer 1 is 0.2mm, the thickness of the core layer 2 is 25m...

Embodiment 2

[0022] This embodiment is a further improvement on the inner constraining surface layer 1 and the outer constraining surface layer 3 described in Embodiment 1, specifically: the sandwich type sound-permeable window structure of the marine fairing in this embodiment The three-layer structure design is that both the inner constraining surface layer 1 and the outer constraining surface layer 3 are made of FRP, the core layer 2 is made of polyurethane viscoelastic material, and the installation positions and dimensions of other components are the same as those in Embodiment 1.

[0023] This design can effectively reduce the self-noise generated by the surface of the shroud due to turbulent pulsation excitation, and the self-noise can be reduced by up to 90%; it greatly reduces the signal interference of the flow noise to the sonar antenna, and improves the stability of the signal reception of the sonar antenna sex.

[0024] In addition, the sandwich-type sound-permeable window str...

Embodiment 3

[0026] This embodiment is a further improvement on the inner constraining surface layer 1 and the outer constraining surface layer 3 described in Embodiment 1, specifically: the sandwich type sound-permeable window structure of the marine fairing in this embodiment The three-layer structure design is that both the inner constraining surface layer 1 and the outer constraining surface layer 3 are made of titanium alloy, the core layer 2 is made of polyurethane viscoelastic material, and the installation positions and dimensions of other components are the same as those in Example 1.

[0027] This design can effectively reduce the self-noise generated by the surface of the shroud due to turbulent pulsation excitation, and the self-noise can be reduced by up to 92%; it greatly reduces the signal interference of the flow noise to the sonar antenna, and improves the stability of the signal reception of the sonar antenna sex.

[0028] In addition, the sandwich-type sound-transmitting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com