Damping composition containing hydrophilic dispersing type PVC resin and preparation method of damping composition

A PVC resin, dispersed technology, applied in the field of damping materials, can solve the problems of being unable to be used as damping materials, difficult to clean, poor mechanical strength of foaming materials, etc., to achieve convenient storage, transportation and construction spraying, large steric hindrance effect, The effect of increased internal friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

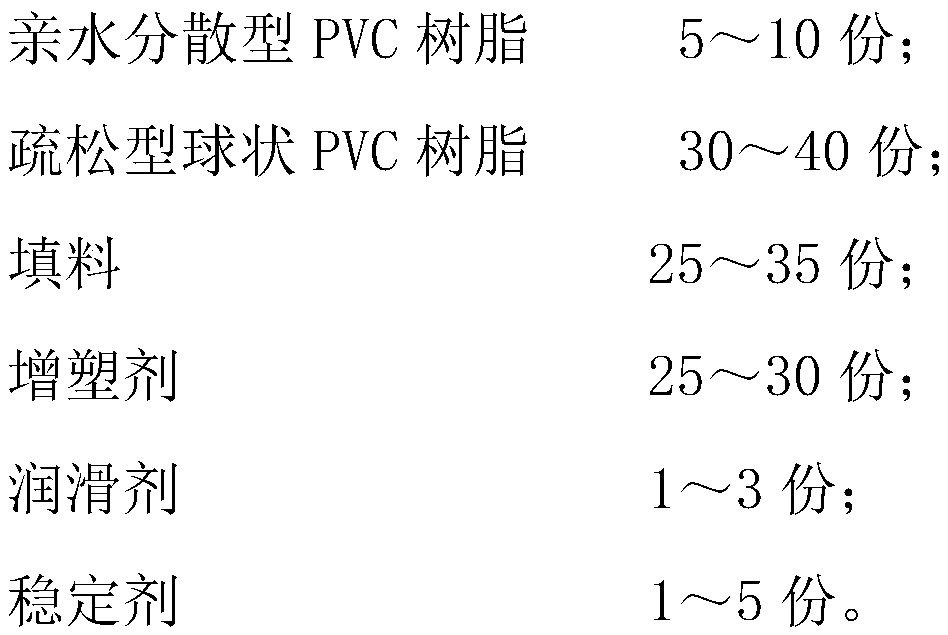

[0038] The present invention also discloses a preparation method of a damping composition containing hydrophilic dispersed PVC resin, the preparation method comprising the following steps:

[0039] 1) At normal temperature, put the hydrophilic dispersed PVC resin, loose spherical PVC resin, filler, and stabilizer in parts by weight into a high-speed disperser for 3 to 5 minutes;

[0040] 2) At room temperature, add plasticizers and lubricants in parts by weight to the high-speed disperser in step 1) to disperse until a uniform paste coating is obtained, vacuumize and stir for 4-10 minutes, and place Aging 18-32 hours.

[0041] 3) Take out the paint prepared in step 2), spray it on the electrophoresis plate, and plasticize it at 120-160° C. for 25-40 minutes to make a 3mm thick sheet.

Embodiment 1

[0043] A method for preparing a hydrophilic dispersed PVC-based damping composition material, comprising the following steps:

[0044] 1) Take each component by the following parts by weight:

[0045]

[0046] Described hydrophilic dispersion type PVC resin obtains by polyvinylbenzene sulfonate sodium, polybutyl acrylate and polyvinyl chloride copolymerization, shown in its structural formula (I):

[0047]

[0048] Wherein: the degree of polymerization of the loose spherical PVC resin is 500, the filler is calcium carbonate, the plasticizer is dioctyl phthalate, the lubricant is liquid paraffin, and the stabilizer is a calcium-zinc stabilizer, specifically ricinoleic acid Calcium and zinc laurate are mixed in a mass ratio of 1:1.

[0049] 2) At normal temperature, put the hydrophilic dispersed PVC resin in parts by weight, loose spherical PVC resin, filler, and stabilizer into a high-speed disperser and disperse for 3 minutes;

[0050] 3) At normal temperature, put the...

Embodiment 2

[0053] A method for preparing a hydrophilic dispersed PVC-based damping composition material, comprising the following steps:

[0054] 1) Take each component by the following parts by weight:

[0055]

[0056] Described hydrophilic dispersion type PVC resin obtains by polyvinylbenzene sulfonate sodium, polyhexyl acrylate and polyvinyl chloride copolymerization, shown in its structural formula (I):

[0057]

[0058] Wherein: the degree of polymerization of the loose spherical PVC resin is 1250, the filler is mica powder, the plasticizer is dioctyl terephthalate, the lubricant is naphthenic oil, and the stabilizer is a lead salt composite stabilizer, specifically For lead stearate.

[0059] 2) At normal temperature, put the hydrophilic dispersed PVC resin in parts by weight, loose spherical PVC resin, filler, and stabilizer into a high-speed disperser and disperse for 3 minutes;

[0060] 3) At normal temperature, put the plasticizer and lubricant in parts by weight into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com