Three-layer core-shell structure interpenetrating network emulsion having high adhesion force to metal substrate and synthesis method of emulsion

A core-shell structure, interpenetrating network technology, applied in the coating and other directions, can solve the problems of unreported damping performance, and achieve the effects of good film-forming performance, wide effective damping temperature range, and high damping factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

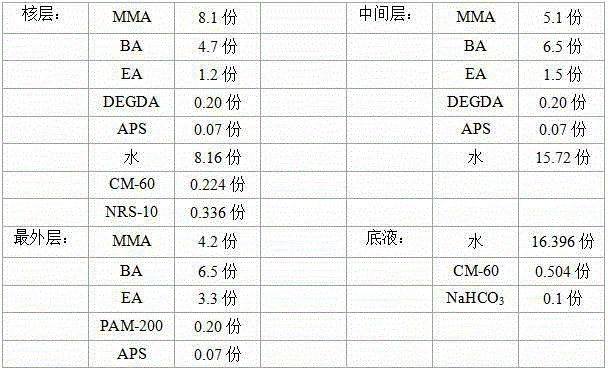

[0020] Embodiment 1: each raw material constitutes as follows by mass parts:

[0021]

[0022] The preparation steps of the three-layer core-shell structure interpenetrating network emulsion of embodiment 1 are as follows:

[0023] (1) Preparation of nuclear pre-emulsion

[0024] According to the above formula, slowly add the core mixed monomer and cross-linking monomer ethylene glycol dimethacrylate (EGDMA) into a container with a certain amount of emulsifier, water and initiator, and stir at a high speed of 900 rpm Pre-emulsification was performed for 30 minutes to prepare a nuclear pre-emulsion.

[0025] Take 15% pre-emulsion from the nuclear pre-emulsion as the seed pre-emulsion.

[0026] (2) Preparation of seed emulsion

[0027] Add 15% nuclear pre-emulsion to a reaction kettle equipped with part of emulsifier and deionized water and protected by inert gas, heat to 82°C to initiate polymerization, and keep warm for half an hour after the blue light appears to prepar...

Embodiment 2

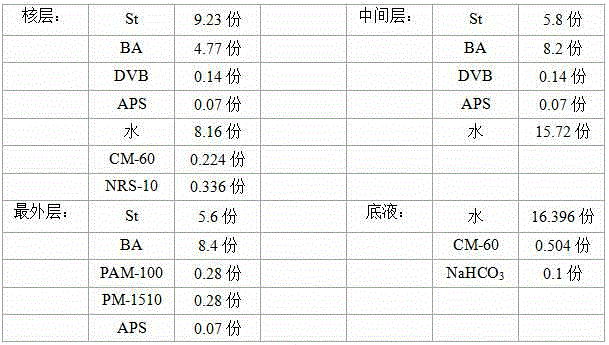

[0037] Embodiment 2: each raw material constitutes as follows by mass parts:

[0038]

[0039] Example 2 Synthesis steps are the same as Example 1.

[0040]The detection of adhesion is carried out according to the national standard "Cross-cut test of paint and varnish film" GB / T 9286-1998, and the damping performance is analyzed by dynamic thermomechanical, and the film-forming performance is analyzed by atomic force microscope. The result is: latex film The adhesion reaches level 1, the damping peak can reach 1.12, the effective damping temperature range (tanσ>0.3) between -40 and 80 °C is about 87 °C, and it has good film-forming properties.

Embodiment 3

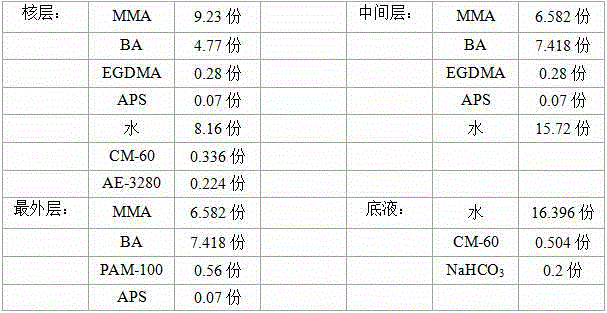

[0041] Embodiment 3: each raw material constitutes as follows by mass parts:

[0042]

[0043] Embodiment 3 synthesis steps are the same as embodiment 1.

[0044] The detection of adhesion is carried out according to the national standard "Cross-cut test of paint and varnish film" GB / T 9286-1998, and the damping performance is analyzed by dynamic thermomechanical, and the film-forming performance is analyzed by atomic force microscope. The result is: latex film The adhesion reaches level 1, the damping peak can reach 0.75, the effective damping temperature range (tanσ>0.3) between -40 and 80 °C is about 60 °C, and it has good film-forming properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective damping temperature range | aaaaa | aaaaa |

| Effective damping temperature range | aaaaa | aaaaa |

| Effective damping temperature range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com