A method of acid -resistant alkali -resistant rubber shoe soles and preparation methods

A rubber sole, acid and alkali resistance technology, applied in shoe soles, footwear, clothing and other directions, can solve the problems of mechanical strength, physical performance decline, product cost increase, loss of work ability, etc., to speed up the vulcanization reaction rate, improve moisture resistance Slippery performance, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

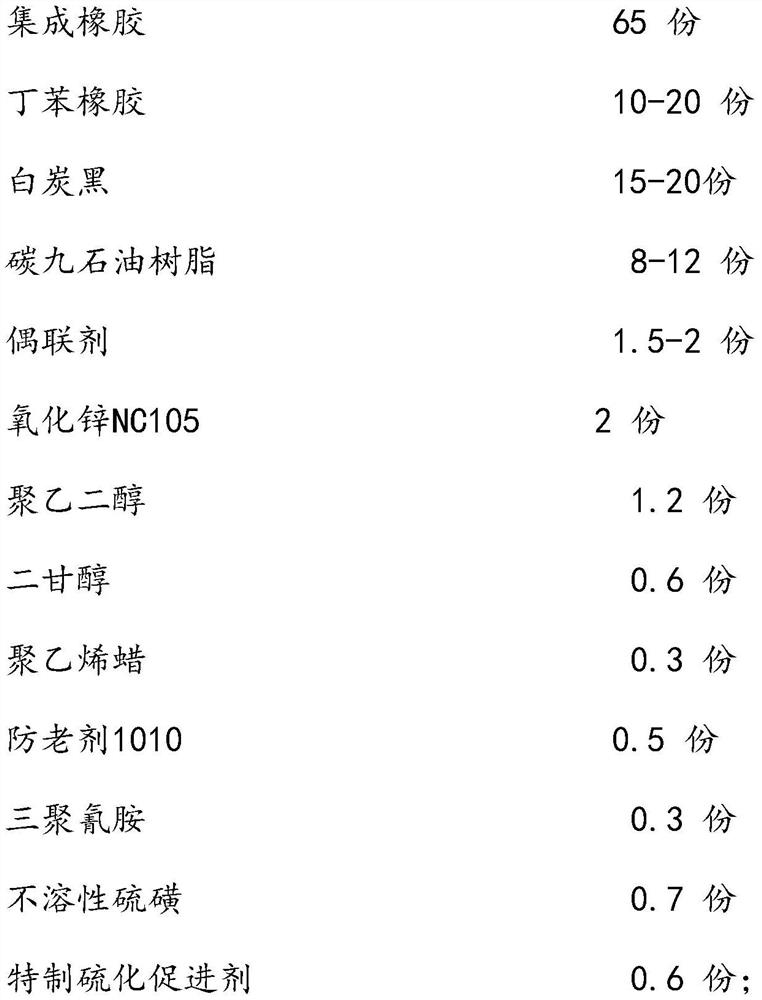

[0032] In the present embodiment, a kind of acid and alkali resistant rubber sole is prepared from the raw materials of the following components by weight:

[0033]

[0034]

[0035] Integrated rubber is a pilot product of PetroChina Lanzhou Petrochemical Company. The mass fraction of styrene is 25%, the mass fraction of isoprene is 40%, and the mass fraction of butadiene is 35%. Among them, 1,2-structure butadiene in butadiene Diene mass fraction is 78%;

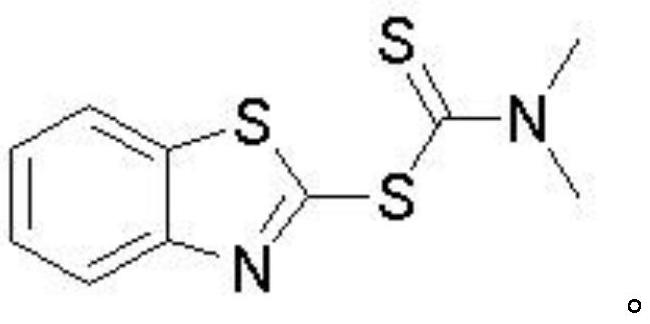

[0036] Put the rubber materials of the component materials except insoluble sulfur, vulcanization accelerator TMTD, and vulcanization accelerator NS into the banbury mixer, deglue at 118°C, leave at room temperature for 24 hours, and then mix on the double-roller open mill. Add accurately weighed insoluble sulfur and a special vulcanization accelerator. After mixing evenly, the sheet is uniformly released. Finally, the material is cut into the shape of a shoe sole and put into a rubber shoe mold for vulcanization. The...

Embodiment 2

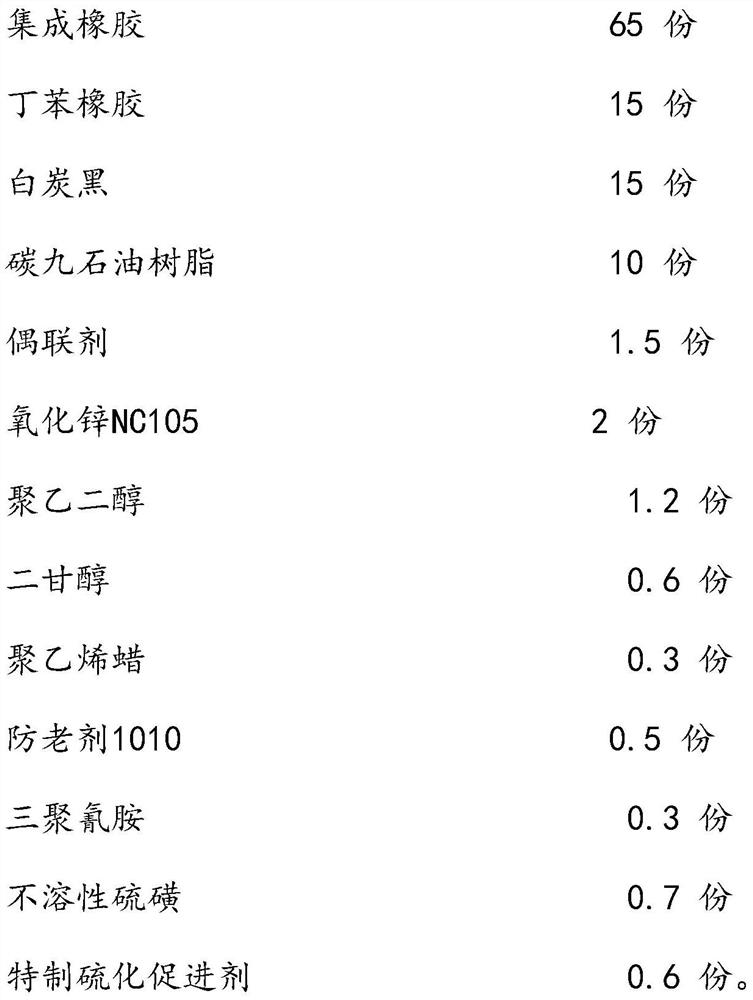

[0038] In the present embodiment, the preparation method of a kind of acid and alkali resistant rubber sole is basically the same as the preparation method in Example 1, the difference is:

[0039] 150,210 parts of styrene-butadiene rubber and 1108 parts of C9 petroleum resin PR in embodiment 2.

Embodiment 3

[0041] In the present embodiment, the preparation method of a kind of acid and alkali resistant rubber sole is basically the same as the preparation method in Example 1, the difference is:

[0042] In Example 3, 150,220 parts of styrene-butadiene rubber, 20 parts of white carbon black, 11,012 parts of C9 petroleum resin, and 692 parts of coupling agent Si.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com