1-3 composite piezoelectric fiber/polymer composite damping material and preparation method thereof

A composite damping material, piezoelectric fiber technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, material selection for piezoelectric devices or electrostrictive devices, device material selection, etc. , adapt to the problems of poor surface performance, etc., to achieve the effect of improving the damping factor and the damping effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

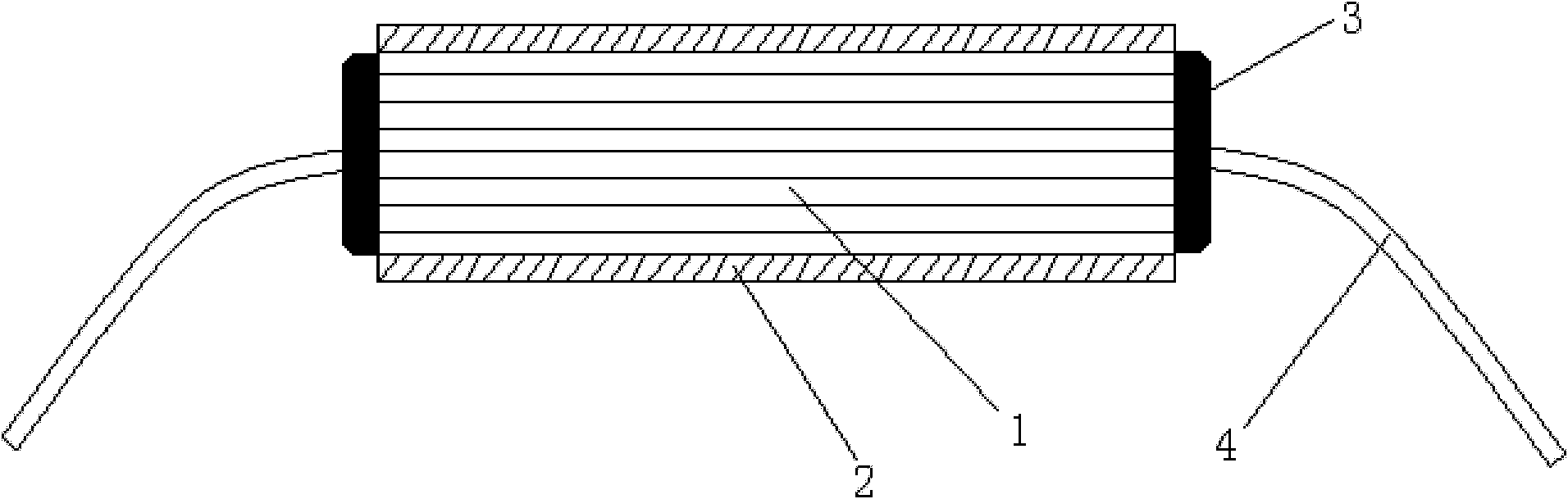

[0046] Such as figure 1 The shown 1-3 composite piezoelectric fiber / polymer composite damping material includes several PZT piezoelectric fibers 1 that are polarized along the length direction and a polymer layer 2 that is coated on the piezoelectric fiber. Both ends of the PZT piezoelectric fiber 1 are bonded with organic conductive silver paste 3 , and electrodes 4 are led out through organic conductive silver paste 3 . Wherein, each polarized PZT piezoelectric fiber is directly polarized by applying voltage at both ends or is obtained by segmentally applying voltage to the PZT piezoelectric fiber; the thickness of the polymer layer 2 is the same as that of the piezoelectric fiber 1 diameter is equivalent.

[0047] A damping system comprising such as figure 1 Shown 1-3 composite piezoelectric fiber / polymer composite damping material and the external resistance that is connected with the lead-out electrode 4 of described composite damping material; The resistance value of...

Embodiment 2

[0052] Preparation of 1-3 composite piezoelectric fiber / polymer composite damping strips and damping system: 1) The PZT-5H2 piezoelectric fiber with a diameter of 0.8mm and a length of 30mm is polarized along the length direction, and the polarization along the length direction It is obtained by directly polarizing the two ends of the PZT piezoelectric fiber with a voltage, where the polarization electric field is 500V / mm, and the piezoelectric coefficient d 33 It is 370pC / N.

[0053] 2) Arrange the 8 polarized piezoelectric fibers tightly in a row, then bond the electrodes at both ends of the piezoelectric fibers together with organic conductive silver paste, and lead out the electrodes with wires;

[0054] Choose 8 polarized piezoelectric fibers closely arranged in 30×10×2mm 3 In the mould, the electrodes at both ends are bonded together with organic conductive silver paste, and the electrodes are drawn out with wires. Pouring with epoxy resin, wrapping piezoelectric fiber...

Embodiment 3

[0058] Preparation of 1-3 composite piezoelectric fiber / polymer composite damping strips and damping system: 1) The PZT-5H2 piezoelectric fiber with a diameter of 0.1mm and a length of 150mm is polarized along the length direction, and the polarization along the length direction It is obtained by directly polarizing the two ends of the PZT piezoelectric fiber with a voltage, where the polarization electric field is 500V / mm, and the piezoelectric coefficient d 33 It is 370pC / N.

[0059] 2) Arrange 15 polarized piezoelectric fibers closely in a row, then bond the electrodes at both ends of the piezoelectric fibers together with organic conductive silver paste, and lead out the electrodes with wires;

[0060] Choose 15 polarized piezoelectric fibers closely arranged in 150×2×0.3mm 3 In the mould, the electrodes at both ends are bonded together with organic conductive silver paste, and the electrodes are drawn out with wires. Pouring with epoxy resin, wrapping the piezoelectric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com