Flame-retardant high-damping rubber and preparation method of damping shock pad of flame-retardant high-damping rubber

A high damping and rubber technology, applied in the field of damping materials, can solve the problems of low tensile strength, no flame retardancy, small maximum loss factor, etc., and achieve high damping factor, good aging resistance and wide temperature range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

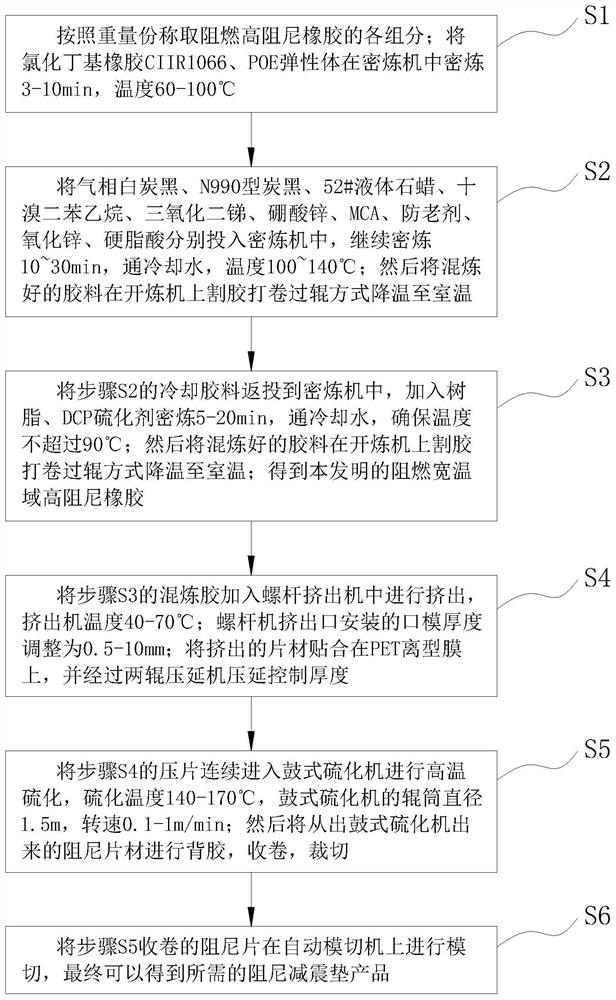

[0023] see figure 1 , the present embodiment provides a technical solution: a preparation method of a flame-retardant high-damping rubber and its damping and shock absorbing pad, and the composition content and parts by weight of the flame-retardant high-damping rubber are as follows:

[0024] Chlorinated butyl rubber CIIR1066-100 parts, POE elastomer-10 parts, white carbon black-5 parts, N990 carbon black-30 parts, 52# liquid paraffin-2 parts, decabromodiphenylethane-40 parts, Antimony trioxide-20 parts, zinc borate-20 parts, MCA-2 parts, anti-aging agent 1076-2 parts, anti-aging agent 2246-1 parts, zinc oxide-5 parts, stearic acid-2 parts, 201 resin-50 parts Parts, DCP vulcanizing agent-1.3 parts.

[0025] The preparation method of above-mentioned damping rubber and damping shock absorbing pad thereof is as follows:

[0026] S1: Mix chlorinated butyl rubber CIIR1066 and POE elastomer in an internal mixer for 5 minutes at a temperature of 80°C;

[0027] S2: Put fumed white...

Embodiment 2

[0035] see figure 1 , the present embodiment provides a technical solution: a preparation method of a flame-retardant high-damping rubber and its damping and shock absorbing pad, and the composition content and parts by weight of the flame-retardant high-damping rubber are as follows:

[0036] Chlorinated butyl rubber CIIR1066-100 parts, POE elastomer-5 parts, white carbon black-3 parts, N990 carbon black-30 parts, 52# liquid paraffin-8 parts, decabromodiphenylethane-30 parts, Antimony trioxide-15 parts, zinc borate-15 parts, MCA-10 parts, anti-aging agent 1076-2 parts, anti-aging agent 2246-1 parts, zinc oxide 5-parts, stearic acid-2 parts, 201 resin-80 parts Parts, DCP vulcanizing agent-1.3 parts.

[0037] The preparation method of above-mentioned damping rubber and damping shock absorbing pad thereof is as follows:

[0038] Step S1: Mix chlorinated butyl rubber CIIR1066 and POE elastomer in an internal mixer for 5 minutes at a temperature of 80°C;

[0039] Step S2: Put f...

Embodiment 3

[0045] see figure 1 , the present embodiment provides a technical solution: a preparation method of a flame-retardant high-damping rubber and its damping and shock absorbing pad, and the composition content and parts by weight of the flame-retardant high-damping rubber are as follows:

[0046] Chlorinated butyl rubber CIIR1066-100 parts, POE elastomer-5 parts, white carbon black-5 parts, N990 carbon black-30 parts, 52# liquid paraffin-2 parts, decabromodiphenylethane-30 parts, Antimony trioxide-15 parts, zinc borate-15 parts, MCA-10 parts, anti-aging agent 1076-1 parts, anti-aging agent 2246-2 parts, zinc oxide-5 parts, stearic acid-2 parts, 206 resin-50 parts Parts, DCP vulcanizing agent-1.3 parts.

[0047] The preparation method of above-mentioned damping rubber and damping shock absorbing pad thereof is as follows:

[0048] Step S1: Mix chlorinated butyl rubber CIIR1066 and POE elastomer in an internal mixer for 5 minutes at a temperature of 80°C;

[0049] Step S2: Put f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com