High-temperature resistant high-performance damping adhesive and preparation method thereof

A kind of bonding adhesive, high-performance technology, applied in the direction of adhesive, adhesive type, ester copolymer adhesive, etc., can solve the problems of poor damping performance, poor damping effect, increase follow-up operations, etc., and achieve shear High peel strength, easy promotion and utilization, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

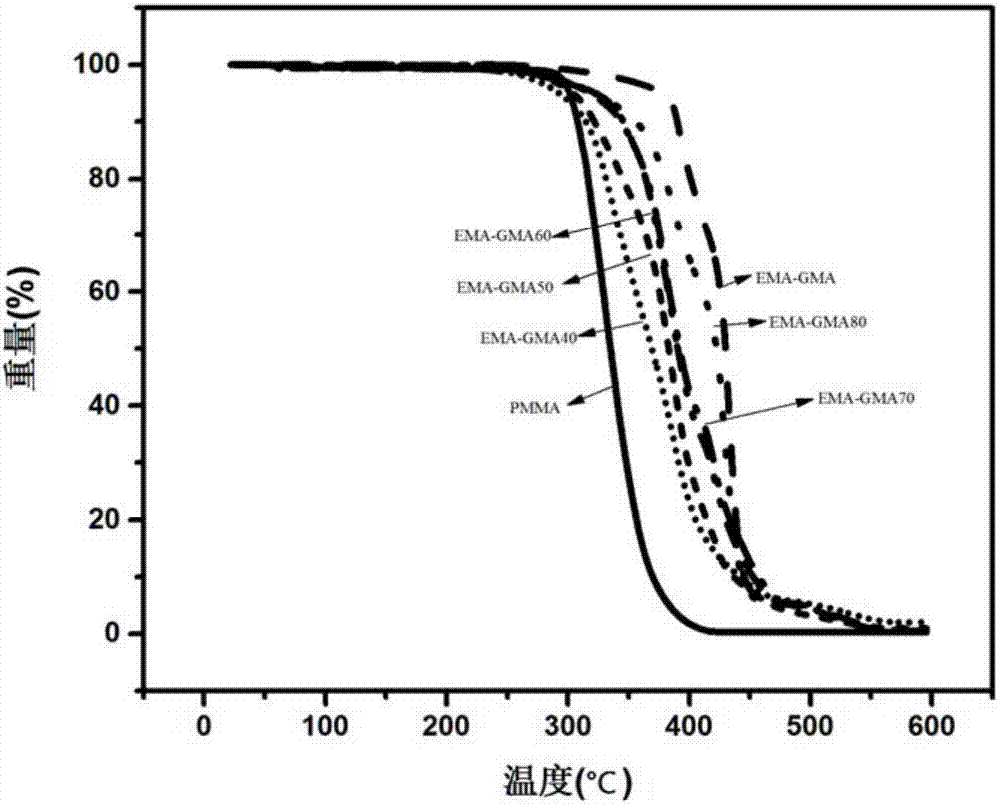

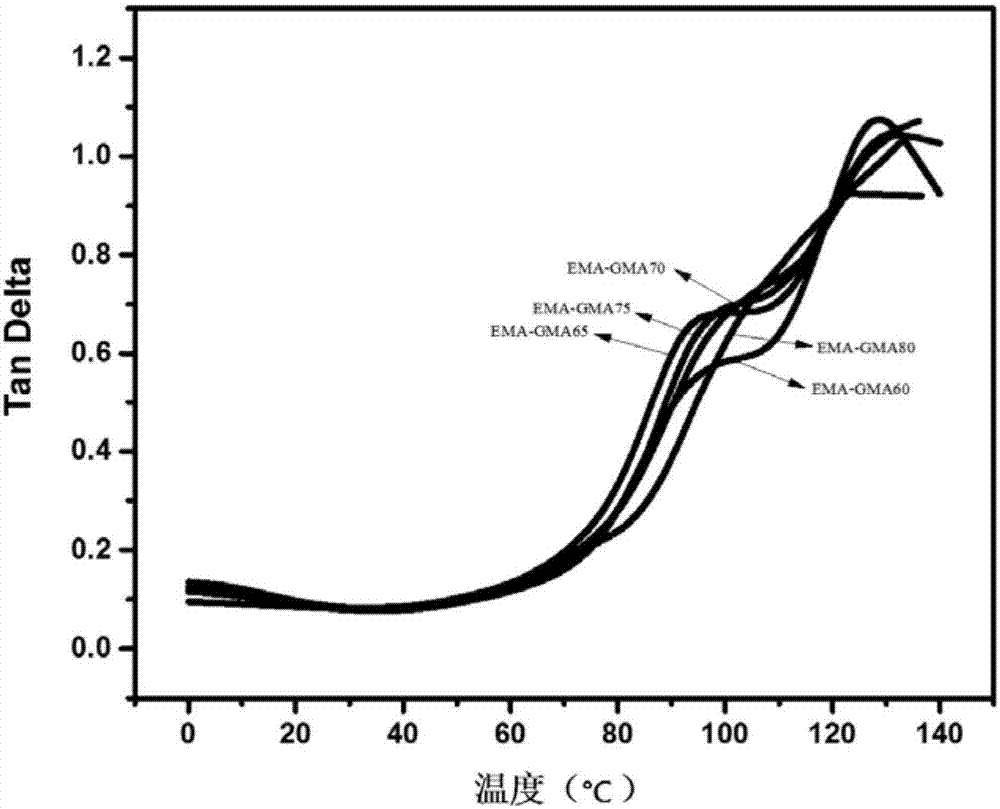

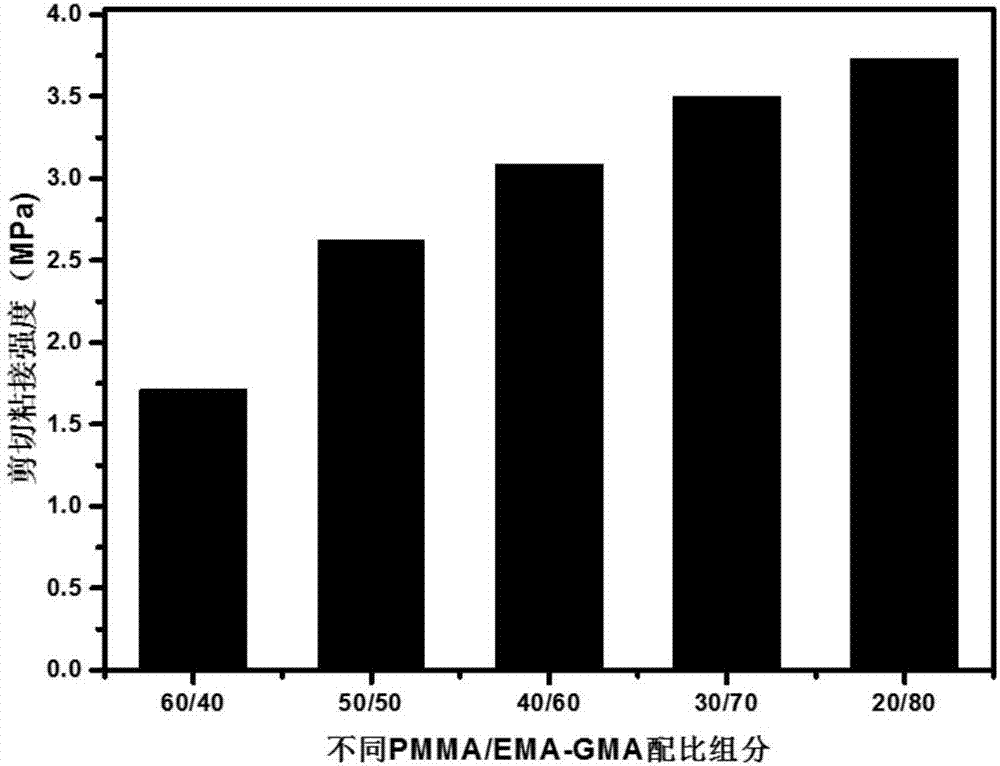

[0025] 40 parts of polymethyl methacrylate with a number average molecular weight of 100,000 and 60 parts of ethylene-methyl acrylate-glycidyl methacrylate random terpolymer with a methacrylic acid content of 24% were mixed at 200°C The damping adhesive colloid blend can be obtained by melting and mixing uniformly through an internal mixer, and the obtained damping adhesive colloid blend is pressed at 200° C. under a pressure of 10 MPa to form a 0.3 mm damping adhesive colloid diaphragm.

[0026] The above diaphragm is sandwiched between two steel plates and pressed at 200°C and 1 MPa pressure to form a constrained damping steel plate. After testing: Tanδ>0.3 at 75-140°C, the maximum damping factor reaches 1.1, the decomposition temperature is 318°C, and the shear peel strength is 3.1MPa.

Embodiment 2

[0028] 35 parts of polymethyl methacrylate with a number average molecular weight of 80,000 and 65 parts of ethylene-methyl acrylate-glycidyl methacrylate random terpolymer with a methacrylic acid content of 13% were mixed at 200°C The damping adhesive colloid blend can be obtained by melting and mixing uniformly through an internal mixer, and the obtained damping adhesive colloid blend is pressed at 200° C. under a pressure of 10 MPa to form a 0.3 mm damping adhesive colloid diaphragm.

[0029] The above diaphragm is sandwiched between two steel plates and pressed at 200°C and 1 MPa pressure to form a constrained damping steel plate. After testing: Tanδ>0.3 at 78-140°C, the maximum damping factor reaches 1, the decomposition temperature is 321°C, and the shear peel strength is 3.6MPa.

Embodiment 3

[0031] 30 parts of polymethyl methacrylate with a number average molecular weight of 100,000 and 70 parts of ethylene-methyl acrylate-glycidyl methacrylate random terpolymer with a methacrylic acid content of 24% were mixed at 200°C The damping adhesive colloid blend can be obtained by melting and mixing uniformly through an internal mixer, and the obtained damping adhesive colloid blend is pressed at 200° C. under a pressure of 10 MPa to form a 0.3 mm damping adhesive colloid diaphragm.

[0032] The above diaphragm is sandwiched between two steel plates and pressed at 200°C and 1 MPa pressure to form a constrained damping steel plate. After testing: Tanδ>0.3 at 80-140°C, the maximum damping factor reaches 1, the decomposition temperature is 322°C, and the shear peel strength is 3.5MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| Damping temperature range | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com