Ether-linkage-containing polyester type polyurethane damping material and preparation method thereof

A polyester polyurethane and damping material technology, which is applied in the field of organic polymer synthesis, can solve the problems of restricting the use of damping materials and high damping temperature range, and achieves the effects of less by-products, good oil resistance and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

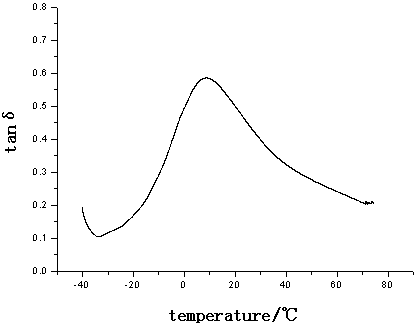

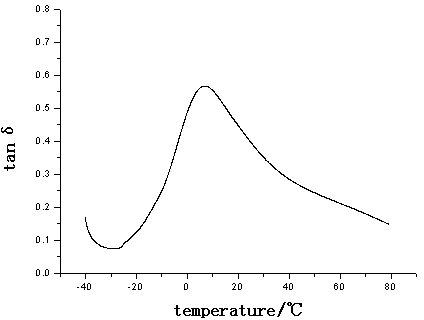

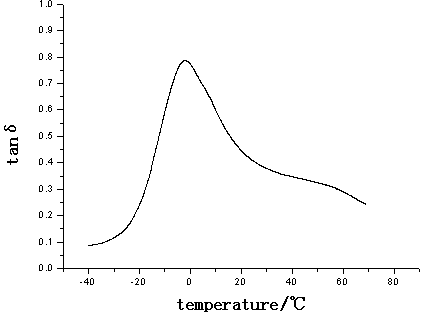

Image

Examples

Embodiment 1

[0032] a. Synthesis of ether bond-containing polyester diol: the feeding method is a three-step method, and propoxy neopentyl glycol is added in three times.

[0033] (1) Add 136g of propoxy neopentyl glycol and 119g of succinic acid into a four-necked flask equipped with a stirrer, a thermometer, and nitrogen, pass through nitrogen, condensate, and raise the temperature. React for 4 hours. The purpose of feeding condensed water is that the product water is distilled out, and guarantees that reactant still remains in the four-necked flask and continues to react.

[0034] (2) Cool the reaction solution to 150°C, add 62g of propoxyneopentyl glycol, and react at 200±5°C for 6 hours.

[0035] (3) Cool the reaction liquid to 150°C, add 55g propoxy neopentyl glycol and 0.075g tetraisopropyl titanate, react at 200°C±5°C for 8 hours, take samples regularly to monitor the acid value and hydroxyl value of the reaction liquid, wait for When the acid value drops below 0.7mgKOH / g, vacuum...

Embodiment 2

[0041] a. Synthesis of ether bond-containing polyester diol: the feeding method is a two-step method, and propoxy neopentyl glycol is added in two times.

[0042] (1) Add 207.5 g of propoxyneopentyl glycol and 120.2 g of 3,3-dimethylglutaric acid into a four-necked flask equipped with a stirrer, a thermometer and nitrogen gas, and protect it with nitrogen gas at 200 ℃±5℃ for 8 hours.

[0043] (2) Cool down the reaction liquid, add 48.7g propoxy neopentyl glycol and 0.085g tetraisobutyl titanate, react at 220°C±5°C for 8 hours, take samples regularly to monitor the acid value and hydroxyl value of the reaction liquid, wait for the acid value When it drops below 0.7mgKOH / g, vacuumize for 1 hour at a vacuum degree of 0.095 MPa, and the measured acid value and hydroxyl value are 0.3mgKOH / g and 61.9mgKOH / g respectively, and an ether bond-containing polyester bismuth with a number average molecular weight of 1800 is obtained. Alcohol is polydimethylglutarate propoxy neopentyl glyco...

Embodiment 3

[0049] a. Synthesis of ether bond-containing polyester diol: the feeding method is a three-step method, and propoxy neopentyl glycol is added in three times.

[0050] (1) Add 149g of propoxyneopentyl glycol and 124.8g of adipic acid into a four-necked flask equipped with a stirrer, a thermometer and nitrogen, and protect it with nitrogen. After distilling off water, react at 160°C±5°C for 4 hours.

[0051] (2) Cool down the temperature of the reaction solution, add 72g of propoxy neopentyl glycol, and react at 200±5°C for 6 hours.

[0052] (3) Cool down the temperature of the reaction solution, add 45g propoxy neopentyl glycol and 0.019g tetraisobutyl titanate, react at 230°C±5°C for 7 hours, when the acid value drops below 0.7mgKOH / g, in a vacuum of 0.095 Vacuumize under MPa for 1 hour, then measure the acid value and hydroxyl value, which are 0.4 mgKOH / g and 49.9 mgKOH / g respectively, and obtain the ether bond-containing polyester diol with a number average molecular weight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Damping temperature range | aaaaa | aaaaa |

| Damping temperature range | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com