A kind of modified hydrogenated nitrile rubber material and its preparation method and application

A hydrogenated nitrile rubber and modified technology, applied in the rubber field, can solve the problems of low temperature resistance and oil resistance, mechanical properties are difficult to combine, reduce oil resistance and mechanical properties, etc. Wide, damping performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The present embodiment provides a kind of preparation method of HNBR / PNB block copolymer, as follows:

[0038] (1) get acrylonitrile content 33wt%, the hydrogenated nitrile butadiene rubber of degree of hydrogenation 92% is dissolved in chlorobenzene, is configured into the hydrogenated nitrile butadiene glue that mass concentration is 10%;

[0039] (2) Get 200g glue solution mass concentration and be 10% hydrogenated nitrile butadiene rubber (conversion is 20g) be placed in the 500ml three-necked flask, weigh 2g norbornene monomer (mass fraction 10%) and add in the hydrogenated nitrile butadiene glue solution , then add Grubbs I catalyst to the mixed glue, stir, and react at 50°C for 8h;

[0040] The mole amount of the Grubbs I generation catalyst is 0.025% of the sum of the double bond moles in the reactants.

[0041] (3) Slowly add the product into ethanol, wash the precipitate, put it in a vacuum oven and dry it to constant weight to obtain the product.

[0042] The...

Embodiment 2~8

[0044] Compared with Example 1, the difference is that the addition amount of norbornene monomer is different, which are respectively 20%, 30%, 40%, 50%, 60%, 80%, and 100% of the mass of hydrogenated nitrile rubber.

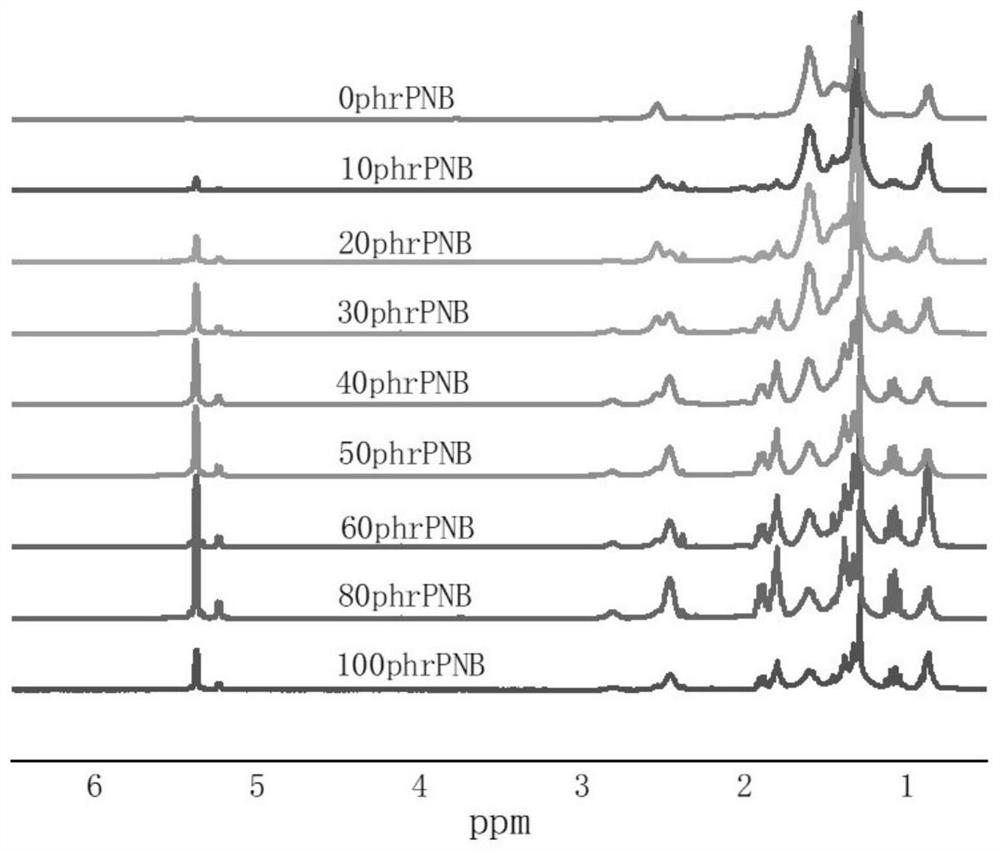

[0045] figure 1 It is the nuclear magnetic spectrum of gained HNBR / PNB block copolymer.

[0046] Calculate the chain segment ratio of hydrogenated nitrile butadiene rubber and polynorbornene in the chain segment of gained HNBR / PNB block copolymer according to nuclear magnetic spectrum, as shown in table 1:

[0047] Table 1

[0048] Hydrogenated nitrile rubber segment content (%) Polynorbornene segment content (%) Example 1 (10%) 87 13 Example 2 (20%) 75 25 Example 3 (30%) 68 32 Example 4 (40%) 50 50 Example 5 (50%) 44 56 Example 6 (60%) 42 58 Example 7 (80%) 35 65 Example 8 (100%) 44 56

[0049] As can be seen from Table 1, along with the addition ratio of norbornene monomer increases, p...

Embodiment 9~14

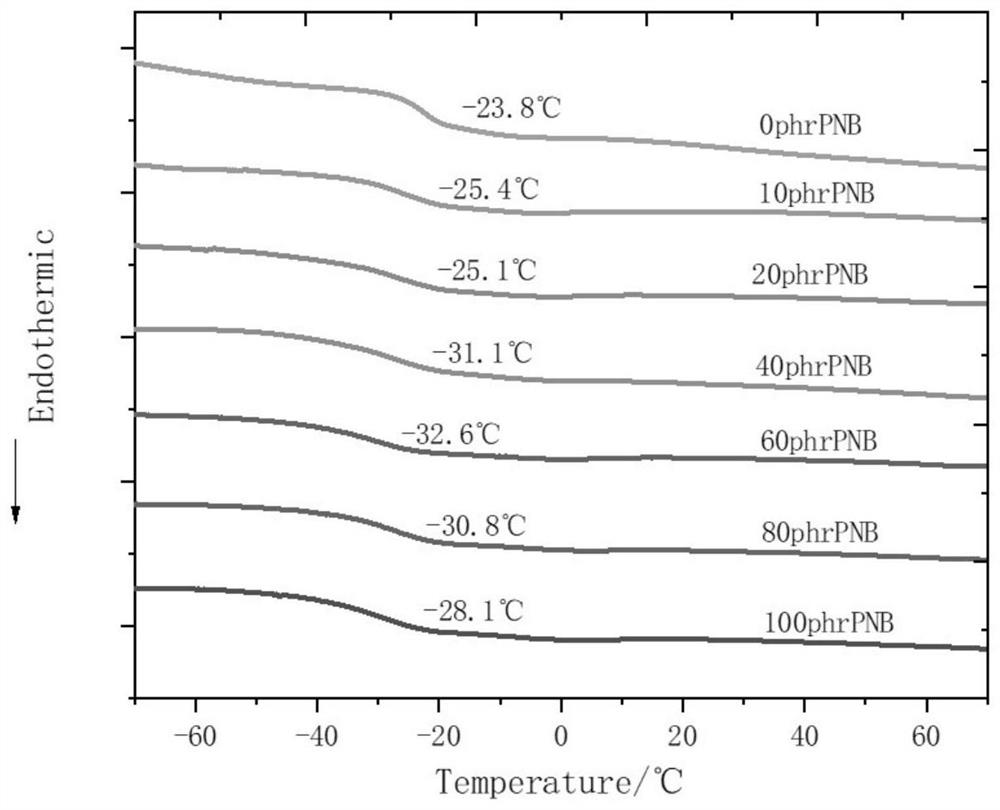

[0051] This embodiment provides a method for preparing a modified hydrogenated nitrile rubber material resistant to low temperature and high damping, including:

[0052] Get respectively with embodiment 1 (10%), embodiment 2 (20%), embodiment 4 (40%), embodiment 6 (60%), embodiment 7 (80%), embodiment 8 (100%) Each 100 parts of the HNBR / PNB block copolymer obtained in the above-mentioned method is respectively configured with 60 parts of naphthenic oil, 40 parts of carbon black N330, 5 parts of zinc oxide, 1 part of stearic acid, 1 part of antioxidant 445, and 1.5 parts of sulfur. Add 0.6 parts of accelerator NS into the internal mixer for mixing; use a flat vulcanizer to vulcanize the mixed rubber at 160 ° C and 10 MPa for 10 to 25 minutes to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| Damping temperature range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com