Super-absorption high-resilience foaming material as well as preparation method and application thereof

A foamed material and high-resilience technology, applied in the field of foamed materials, can solve the problems of not meeting the requirements of high-resilience performance, insignificant shock absorption effect, and decreased mechanical properties of foamed materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

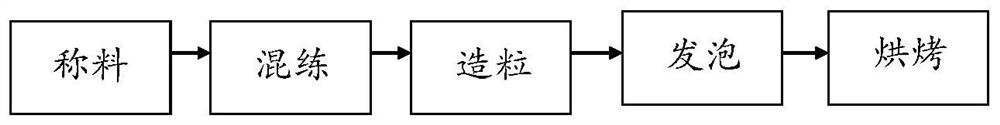

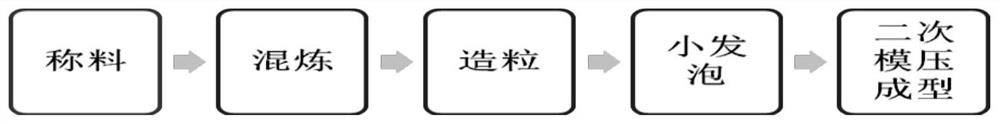

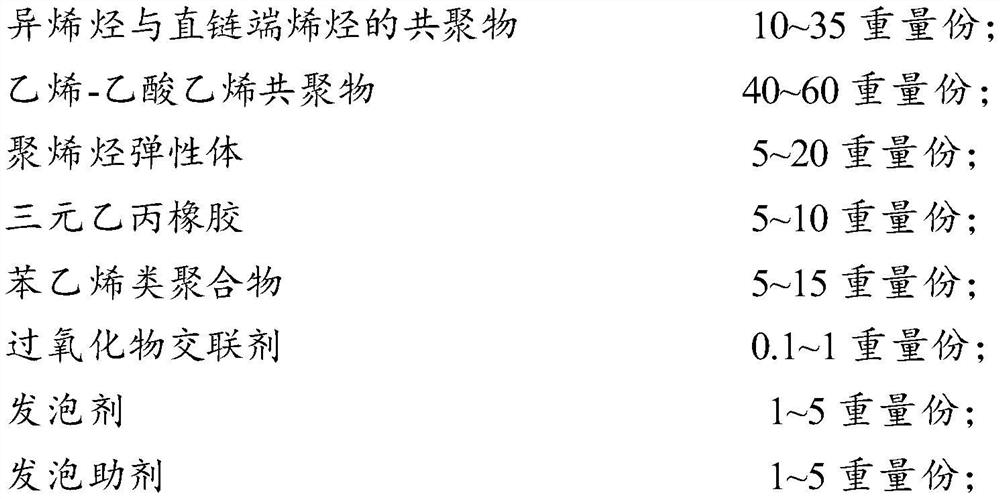

[0063] The present invention also provides a method for preparing the above-mentioned superabsorbent high-impact rebounding foaming material, which includes: a copolymer of isoolefin and linear terminal olefin, ethylene-vinyl acetate copolymer, polyolefin elastomer, terpolymer After the propylene rubber, styrene polymer, peroxide crosslinking agent, foaming agent and foaming aid are mixed, granulated and foamed, a superabsorbent and high-impact rebound foaming material is obtained.

[0064] Among them, the present invention has no special limitation on the sources of all raw materials, which can be commercially available. The copolymer of isoolefin and straight-chain terminal olefin, ethylene-vinyl acetate copolymer, polyolefin elastomer, EPDM rubber, styrene polymer, peroxide crosslinking agent, foaming agent and foaming agent The contents and types of auxiliary agents are the same as those described above, and will not be repeated here.

[0065]Copolymers of isoolefins and ...

Embodiment 1~11 and comparative example 1~7

[0074] Weighing: According to the type and dosage of the formulas in Table 1 and Table 2, DCP and foaming agent are weighed as the first group of materials; stearic acid, zinc stearate and zinc oxide are weighed as the second group of materials; The remaining materials are weighed for the third group of materials.

[0075] Mixing: first pour the third group of materials into the internal mixer, and turn on the machine, wait for the temperature to rise to 80 ° C ~ 85 ° C; pour in the second group of materials; wait for the temperature to rise to 90 ° C ~ 95 ° C Add the third group of materials; when the temperature rises to 100°C-110°C, pour out the mixed materials.

[0076] Material making: Pour the mixed material into the material making machine, and adjust the temperature of the first, second, third, and fourth zones to 75°C, 80°C, 85°C, and 90°C respectively. And the screw speed is adjusted to 40-50 rpm, and the cutting speed is adjusted to 15-20 rpm.

[0077] Foaming: Po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com