Wide-temperature-domain high-damping environment-friendly damping material for electronic product and preparation method thereof

A technology for electronic products and damping materials, applied in the field of wide temperature range high damping environmental protection damping materials and their preparation, can solve the problems of inability to meet the requirements of complex and harsh environments, inability to meet environmental protection requirements, low damping and vibration reduction factors, etc., and achieve environmental protection. The effect of good performance, large resistance and high damping factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

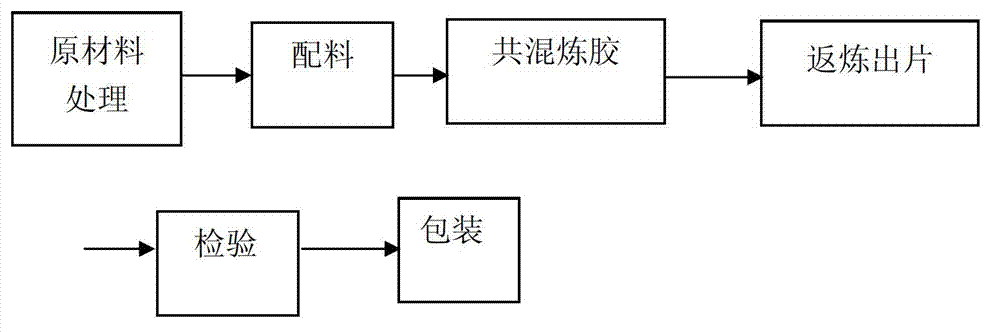

[0034] Such as figure 1 Shown is the flow chart of the preparation process of the damping material of the present invention. The preparation method of the wide temperature range high damping environmental protection damping material for electronic products of the present invention includes the following steps:

[0035] Step (1), raw material treatment: In a fume hood or on a well-ventilated platform, crush the massive brominated p-tertoctylphenol formaldehyde resin, and after sieving, the diameter of the resin particles is required to be no more than 10mm; Wear-resistant carbon black is placed in an oven for drying, the drying temperature is 100-120°C, and the drying time is 4h±10min.

[0036] Step (2), batching: batching is carried out according to the formula, and a balance is used to accurately weigh various raw materials when batching.

[0037] Step (3), blending and mixing rubber: First, add the butyl rubber, brominated p-teroctyl formaldehyde resin, anti-aging agent, di...

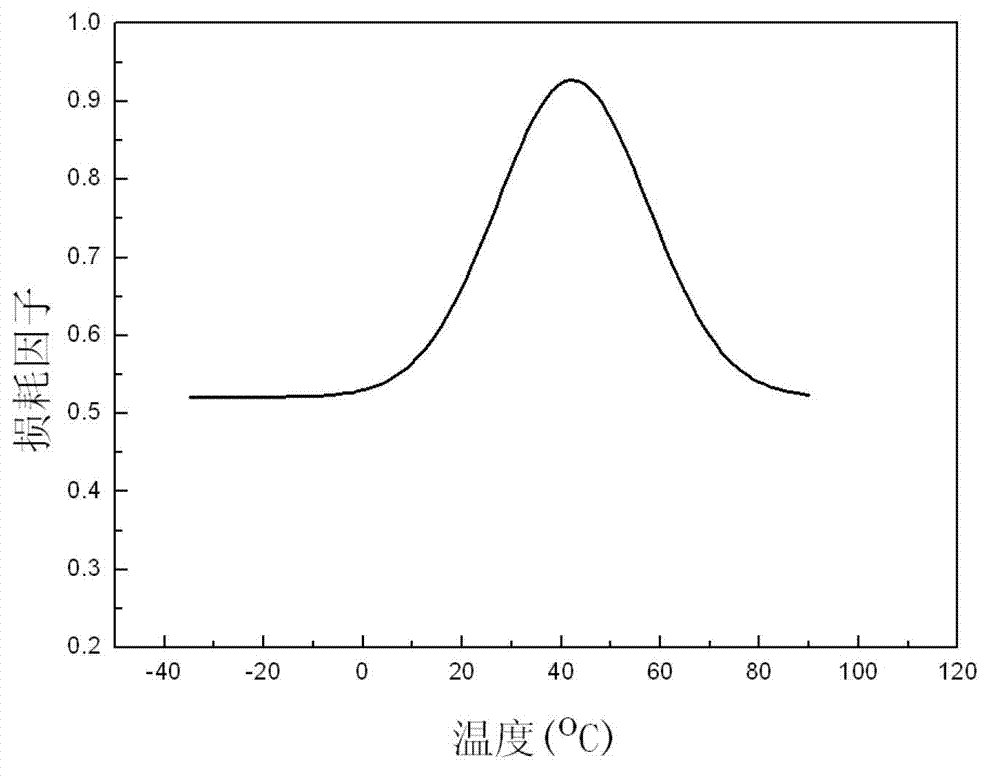

Embodiment 1

[0042] (1) Formula components and content (mass percentage%):

[0043] 46% of butyl rubber component, 4.6% of di-octyl sebacate, 18.3% of olfactory p-tetyl phenolic thiol, 0.5% of anti-aging agent Sp-L, 13.8% of high wear-resistant carbon black N330, Zinc oxide 2.3%, stearic acid 0.7%, small organic molecule AO60 13.8%.

[0044] (2), preparation process:

[0045]On the 16-inch open mill, add the above-mentioned butyl rubber, brominated p-teroctyl formaldehyde resin, anti-aging agent Sp-L, diisooctyl sebacate, zinc oxide, stearic acid and organic small oil in sequence. Molecule AO60 is compounded to obtain masterbatch, and the roller temperature is 55°C during compounding. Then add dried high wear-resistant carbon black N330 to the masterbatch on a 10-inch open mill and mix with a roller temperature of 55°C.

[0046] The mixed rubber material is parked at room temperature for 12 hours, and then re-mixed and rolled out on a 10-inch open rubber mixer. The temperature of the ro...

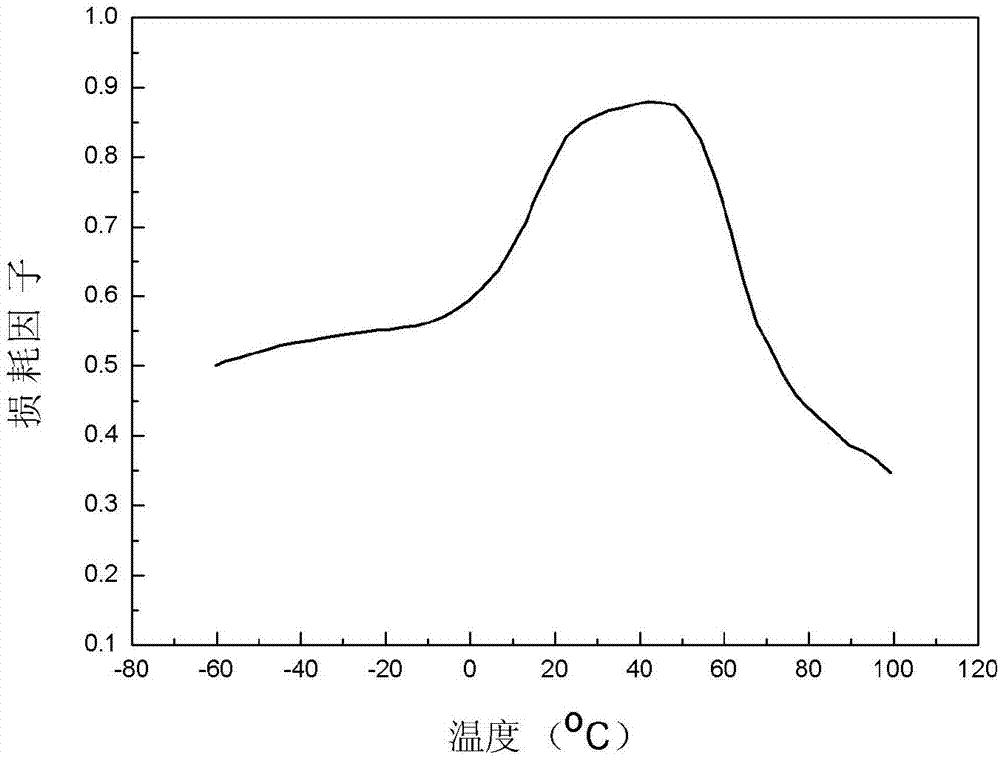

Embodiment 2

[0051] (1), formula components and content (mass percentage%):

[0052] 44% butyl rubber component, 4.4% di-octyl sebacate, 17.6% olfactory p-tert-octyl phenolic sulfatide, 0.4% anti-aging agent Sp-L, 17.5% high wear-resistant carbon black N660, Zinc oxide 2.2%, stearic acid 0.7%, small organic molecule AO60 13.2%.

[0053] (2), preparation process:

[0054] On the 16-inch open mill, add the above-mentioned butyl rubber, brominated p-teroctyl formaldehyde resin, anti-aging agent Sp-L, diisooctyl sebacate, zinc oxide, stearic acid and organic small oil in sequence. Molecule AO60 is compounded to obtain a masterbatch, and the roller temperature is 50°C during compounding. Then add the dried high wear-resistant carbon black N660 to the masterbatch on a 10-inch open mill for mixing, and the roller temperature is 55°C.

[0055] The mixed rubber material is parked at room temperature for 12 hours, and then re-mixed and rolled out on a 10-inch open rubber mixer. The temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com