Control device for pot-entering temperature of strip steel in hot-galvanizing annealing furnace

A technology of temperature control device and annealing furnace, which is applied in the direction of hot-dip galvanizing process, coating, metal material coating process, etc., can solve the problems of zinc liquid temperature drop and zinc liquid temperature rise, etc., to improve galvanizing efficiency and galvanizing efficiency. The effect of zinc quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

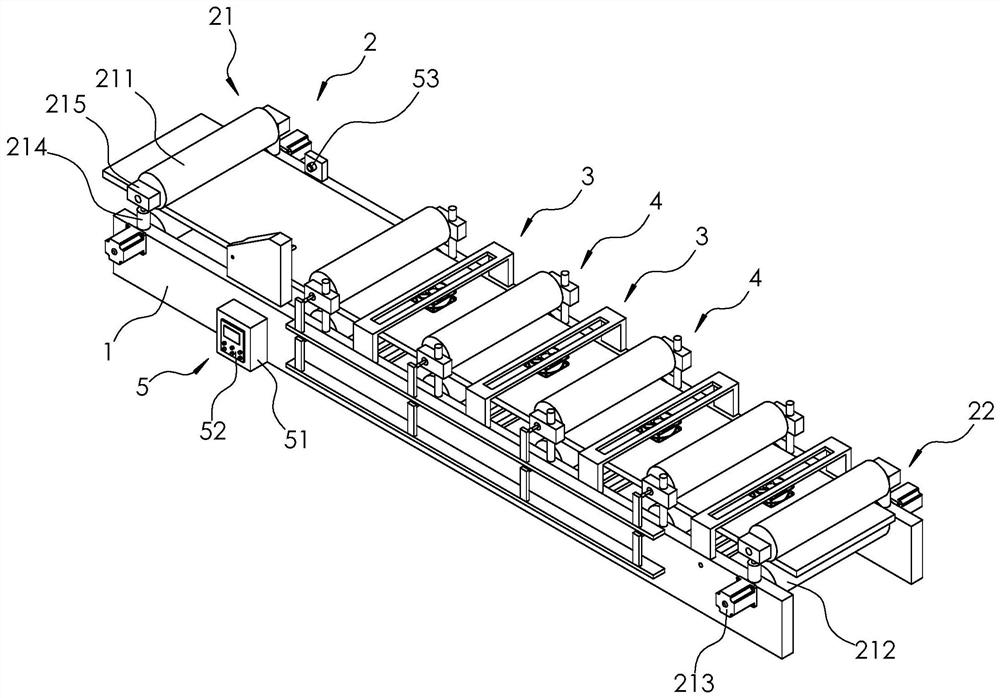

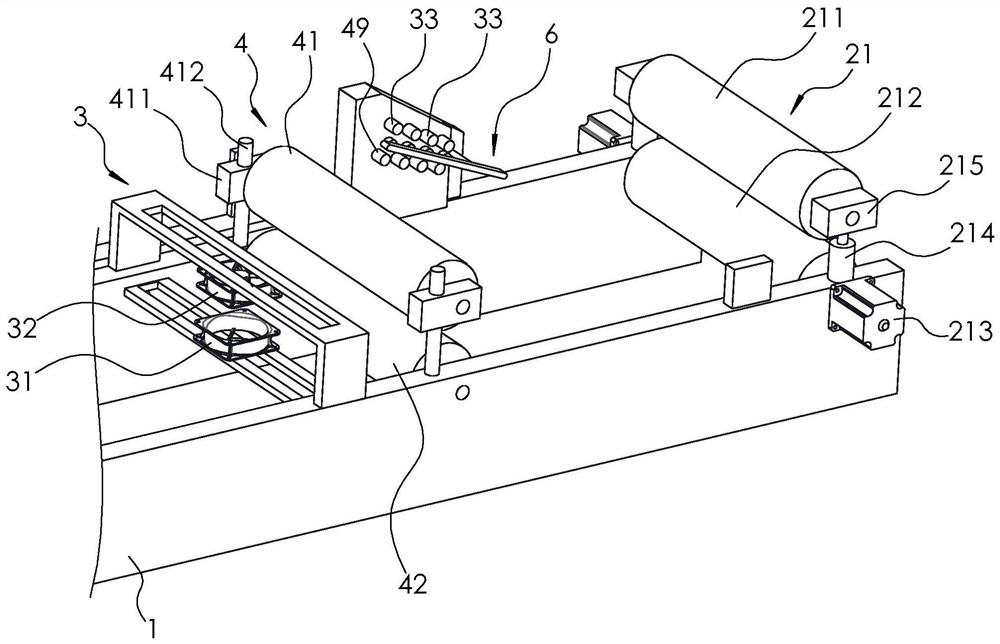

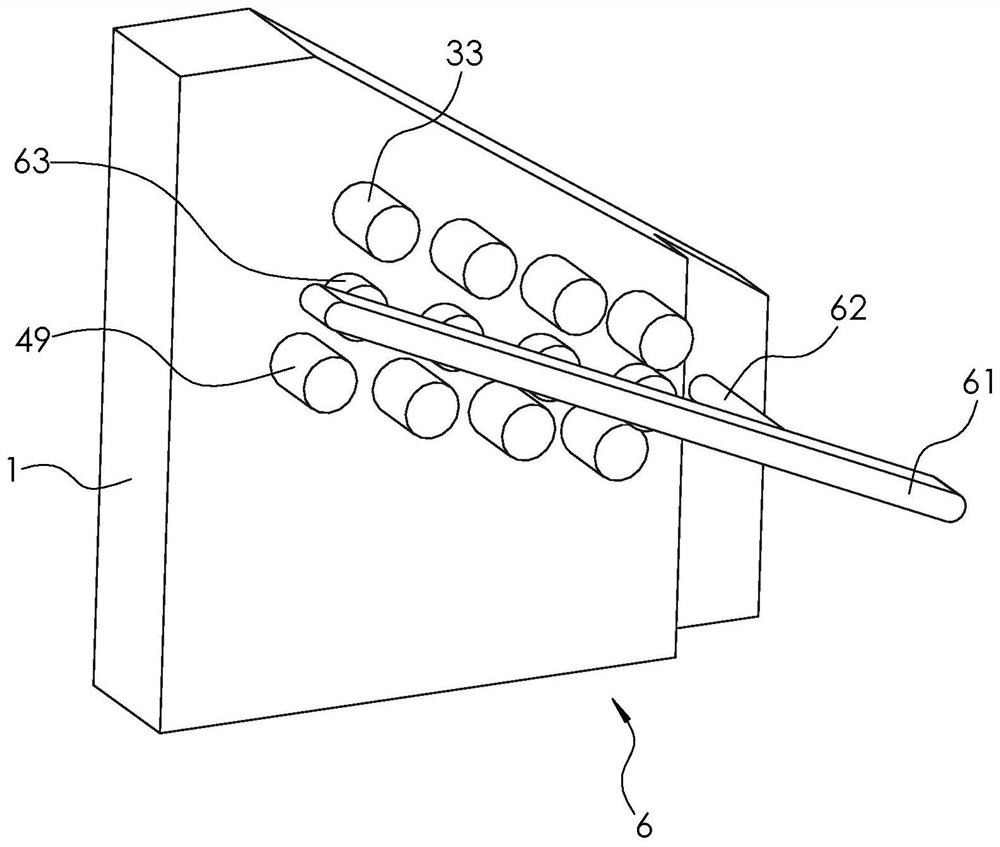

[0042] The following is attached Figure 1-4 The application is described in further detail.

[0043] The embodiment of the present application discloses a device for controlling the temperature of steel strip entering the pot of a hot-dip galvanizing annealing furnace. Such as figure 1 and figure 2 As shown, a hot-dip galvanizing annealing furnace strip steel into the boiler temperature control device, including a bracket 1, the bracket 1 is provided with a conveying mechanism 2, a blowing mechanism 3, a heating mechanism 4, a power supply mechanism 5 and a conductive mechanism 6, and a conveying mechanism 2 It is used to transport the strip steel; the conductive mechanism 6 can make the power supply mechanism 5 supply power to the blowing mechanism 3 or the heating mechanism 4 according to the thickness of the strip steel; the blowing mechanism 3 is used to blow and cool the strip steel; the heating mechanism 4 is used for The strip steel is heated to increase the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com