Device for controlling temperature uniformity of strip steel before entering zinc pot and using method of device

A control device and uniformity technology, applied in heat treatment process control, manufacturing tools, coatings, etc., can solve problems such as temperature inhomogeneity, incomplete alloying of the edge of the strip, spots, etc., to improve the quality of galvanizing, Eliminate the effects of incomplete alloying and uniform temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

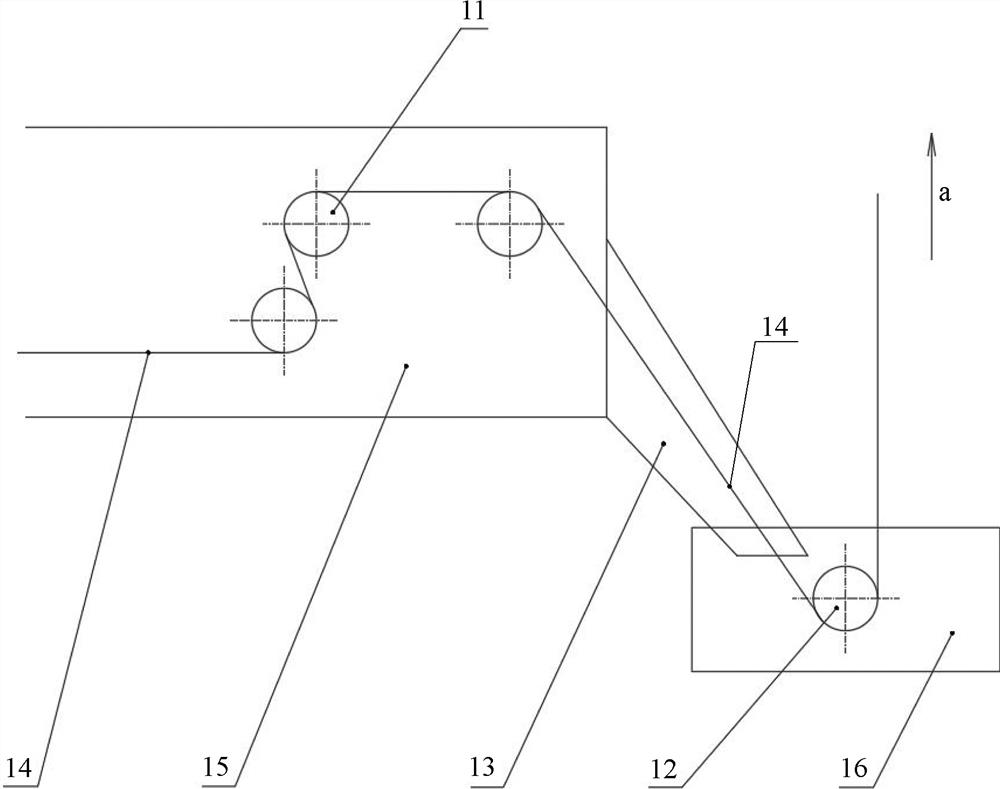

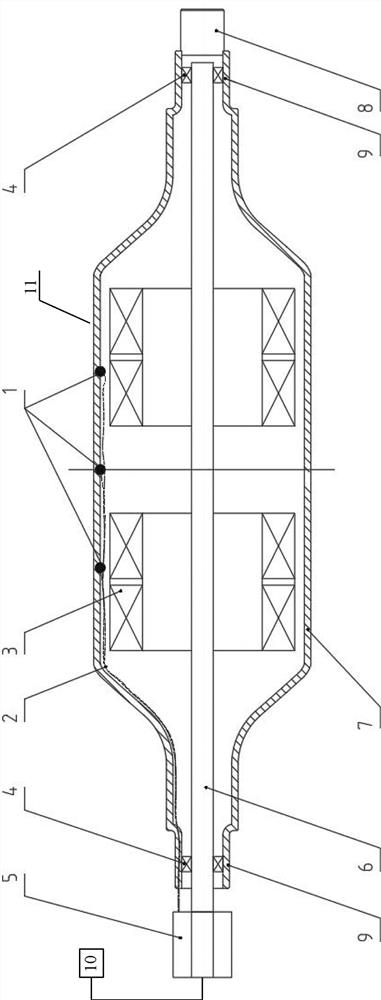

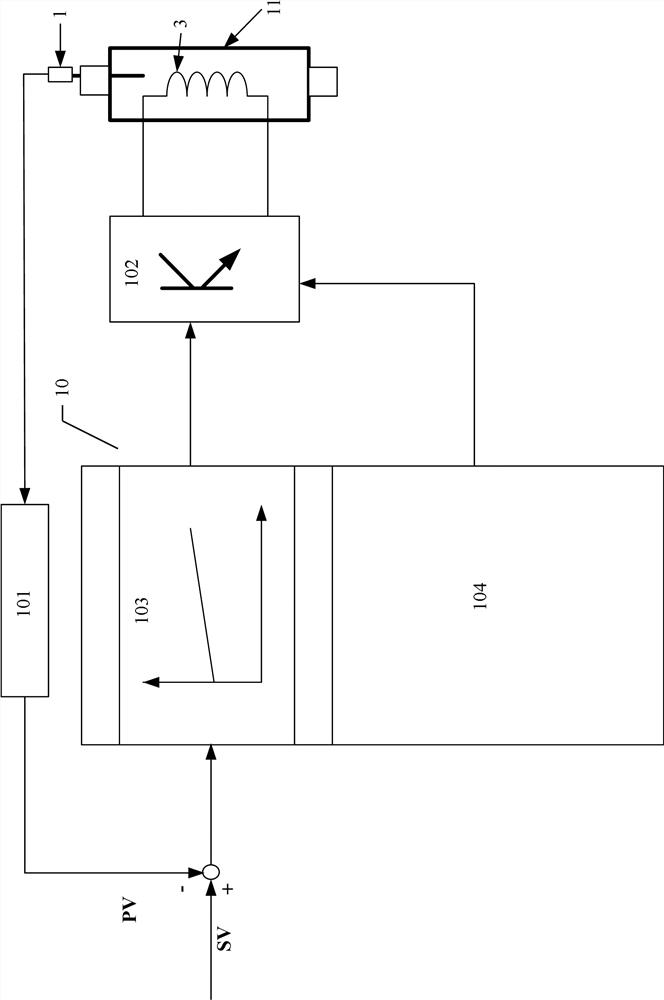

[0026] A control device for temperature uniformity before strip steel enters the zinc pot, comprising heating roll 11, sink roll 12, furnace nose 13, strip steel 14, heat treatment furnace 15 and zinc pot 16, such as Figure 1 ~ Figure 3 As shown, the specific structure is:

[0027] Zinc pot 16 is arranged at the oblique below of heat treatment furnace 15, and the outlet of heat treatment furnace 15 and the mouth of the pot of zinc pot 16 are connected by furnace nose 13, and heating roller 11 is rotatably arranged in heat treatment furnace 15, and each heating roller 11 is all positioned at Horizontal and parallel to each other, zinc liquid is contained in the zinc pot 16, and the sinking roll 16 is rotatably arranged in the zinc pot 16 and the sinking roll 16 is completely submerged below the liquid level of the zinc liquid, and the sinking roll 16 is also located in the horizontal direction and heated The rollers 11 are parallel to each other, and the strip steel 14 is inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com