A method for controlling temperature uniformity during superplastic forming of aluminum alloy parts

A technology for aluminum alloy parts and superplastic forming, which is applied in the temperature uniformity control during superplastic forming of aluminum alloy parts, and in the field of superplastic forming of large-sized aluminum alloy parts, which can solve the problem of uneven deformation, large mold size, and aluminum alloy blanks. Uneven temperature and other problems, to avoid inconsistencies in deformation, reduce production costs, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiment of the present invention will be described in further detail below in conjunction with the accompanying drawings.

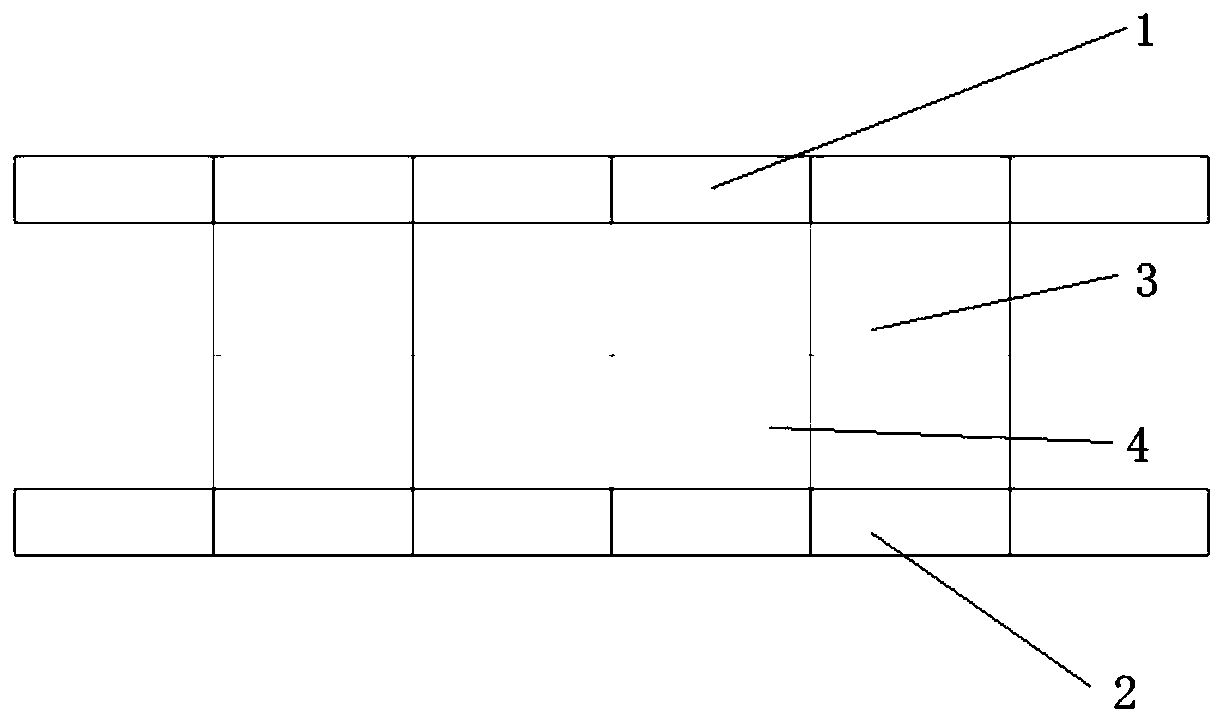

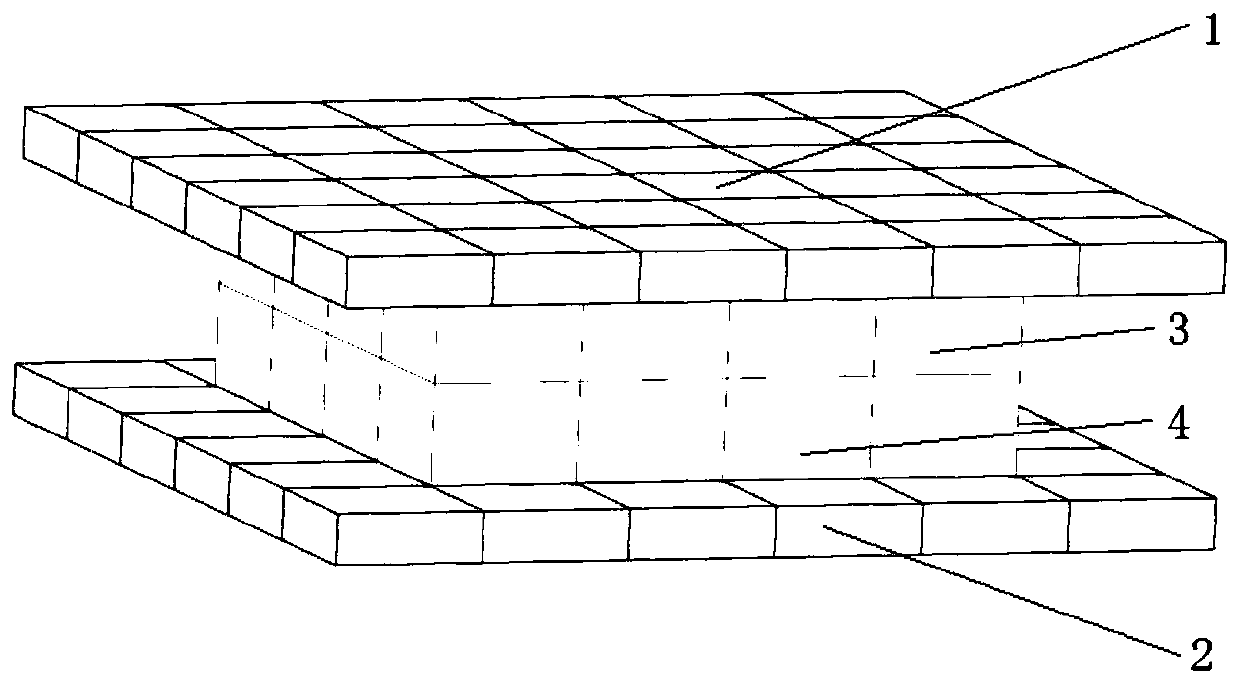

[0028] The temperature uniformity control of the aluminum alloy parts to be done in the present invention during superplastic forming includes: an upper platform 1 for superplastic forming, a lower platform 2 for superplastic forming, an upper mold 3 for a superplastic forming mold, and a lower mold 4 for a superplastic forming mold , as attached figure 1 And attached figure 2 shown.

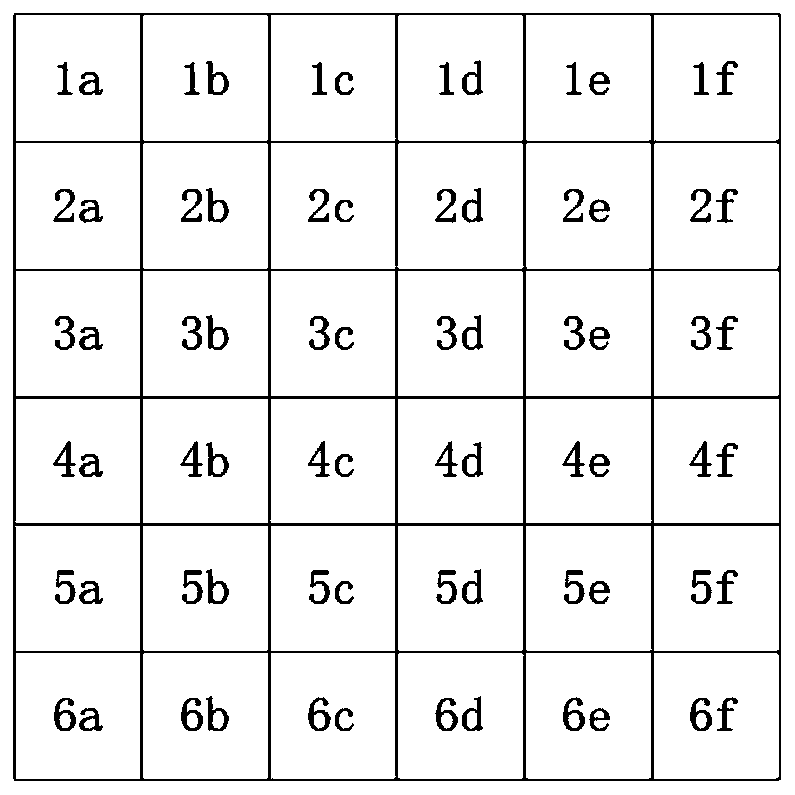

[0029] The upper platform 1 for superplastic forming and the lower platform 2 for superplastic forming respectively include 36 heating zones, and each heating zone can independently carry out heating control; the upper mold 3 of the superplastic forming mold and the lower mold 4 of the superplastic forming mold are respectively divided into 16 Each temperature monitoring area can independently monitor the temperature from time to time. By monitor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com