Wedge-shaped air preheating combustor

A technology for preheating air and burners, used in gas fuel burners, burners, combustion methods, etc., can solve the problems of uneven temperature, difficult ignition, energy waste, etc., to achieve temperature uniformity, uniformity, Ease of installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

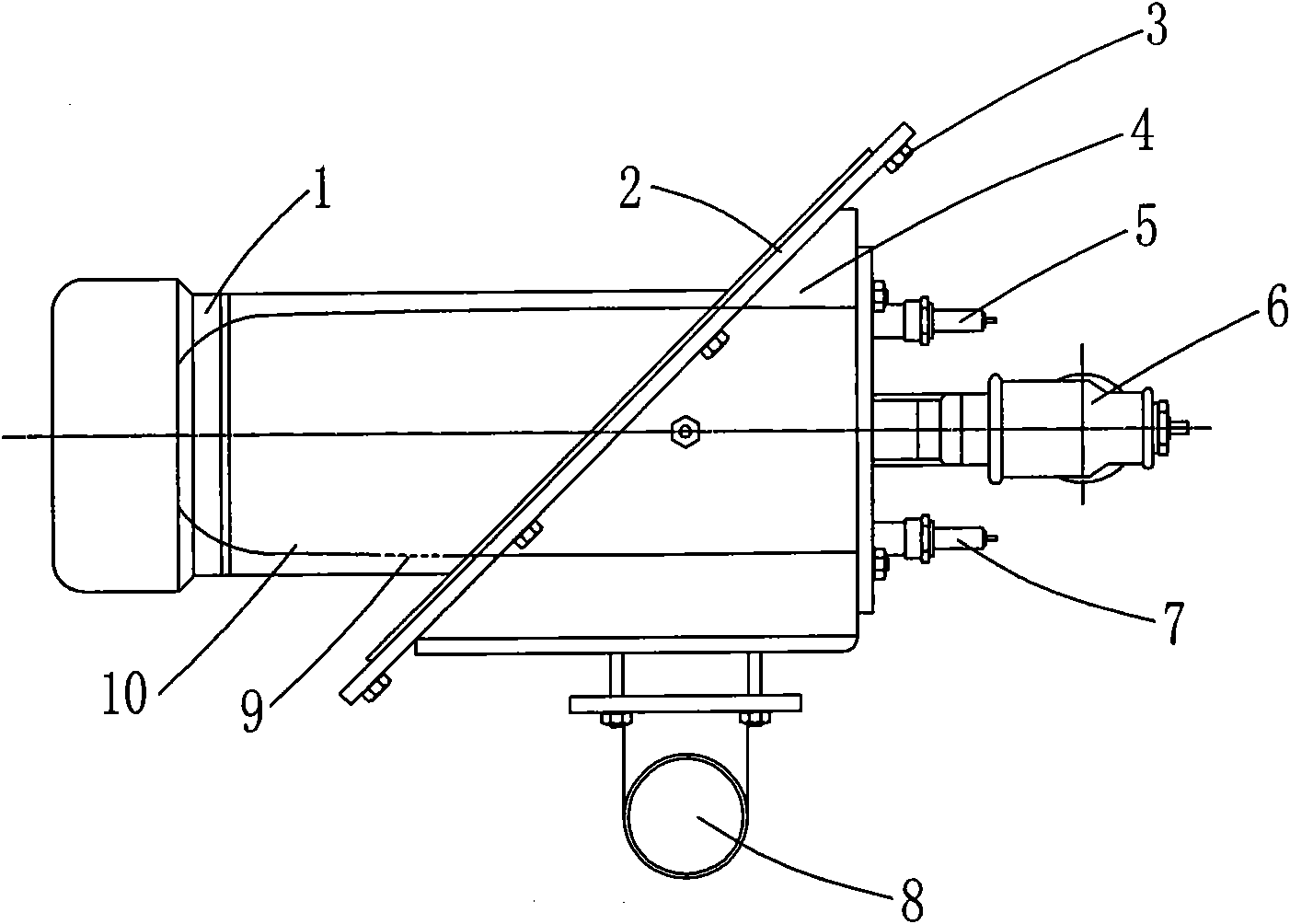

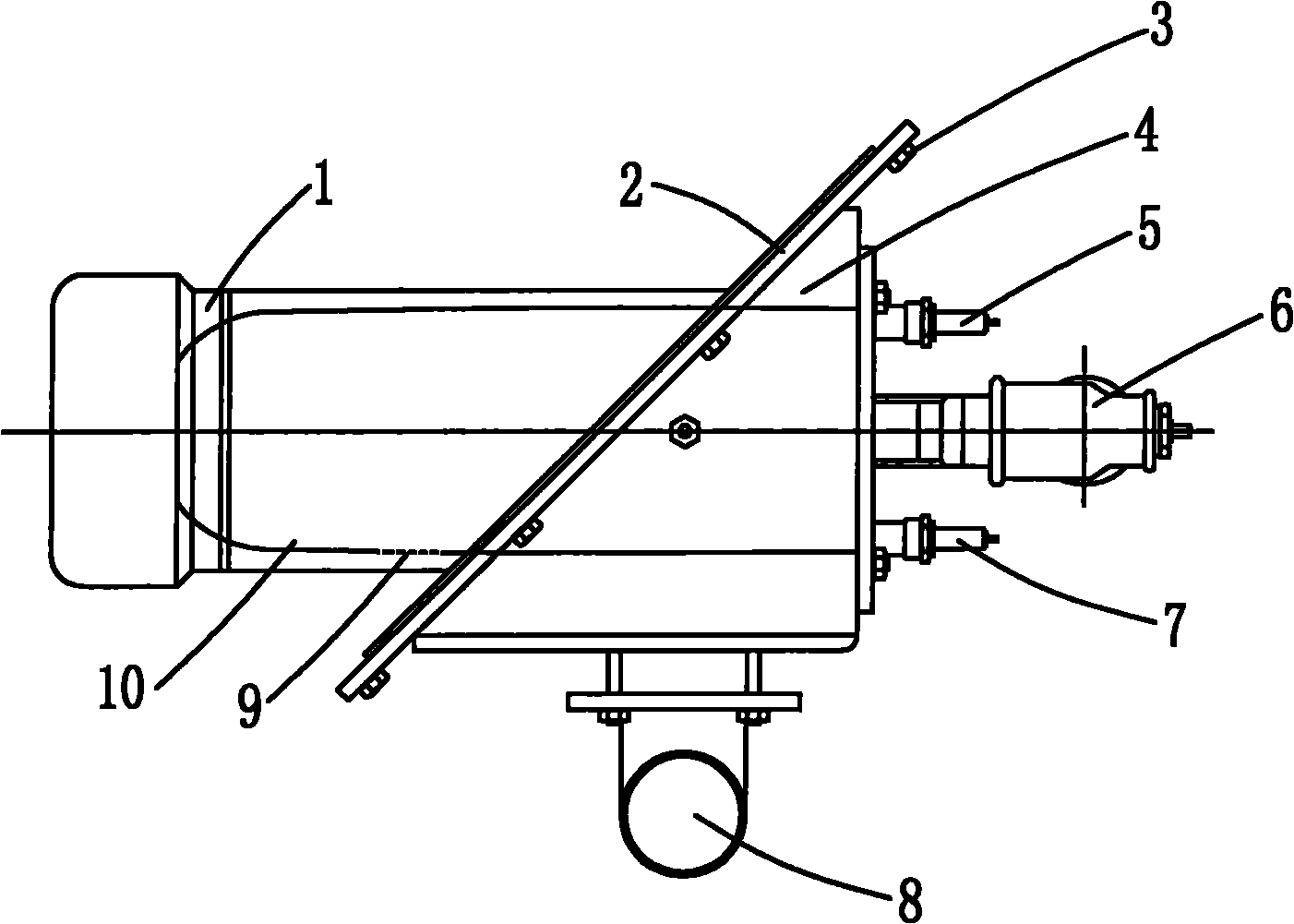

[0019] Example: Combine figure 1 , the preheating air wedge burner of the present embodiment has a cylindrical main burning tube 1, and an inner burner 10 is coaxially arranged in the inner chamber of the main burning tube, and one end of the inner burner 10 (stretching into the main burning tube The end of the inner cavity of the inner burner is gradually closed, and the end of the inner burner communicates with the inner cavity of the main burning tube, and the other end of the inner burner 10 is sealed and connected with the end of the main burning tube 1. There is a gas connecting pipe 6 communicating with the inner cavity of the inner burner 10; the outer wall of the main burning tube near the closed end is radially connected with an air intake pipe 8, and the outer wall of the inner burner away from the closed end is provided with a number of air intake holes 9, The inlet pipe 8 communicates with the inner cavity of the inner burner through the interlayer between the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com