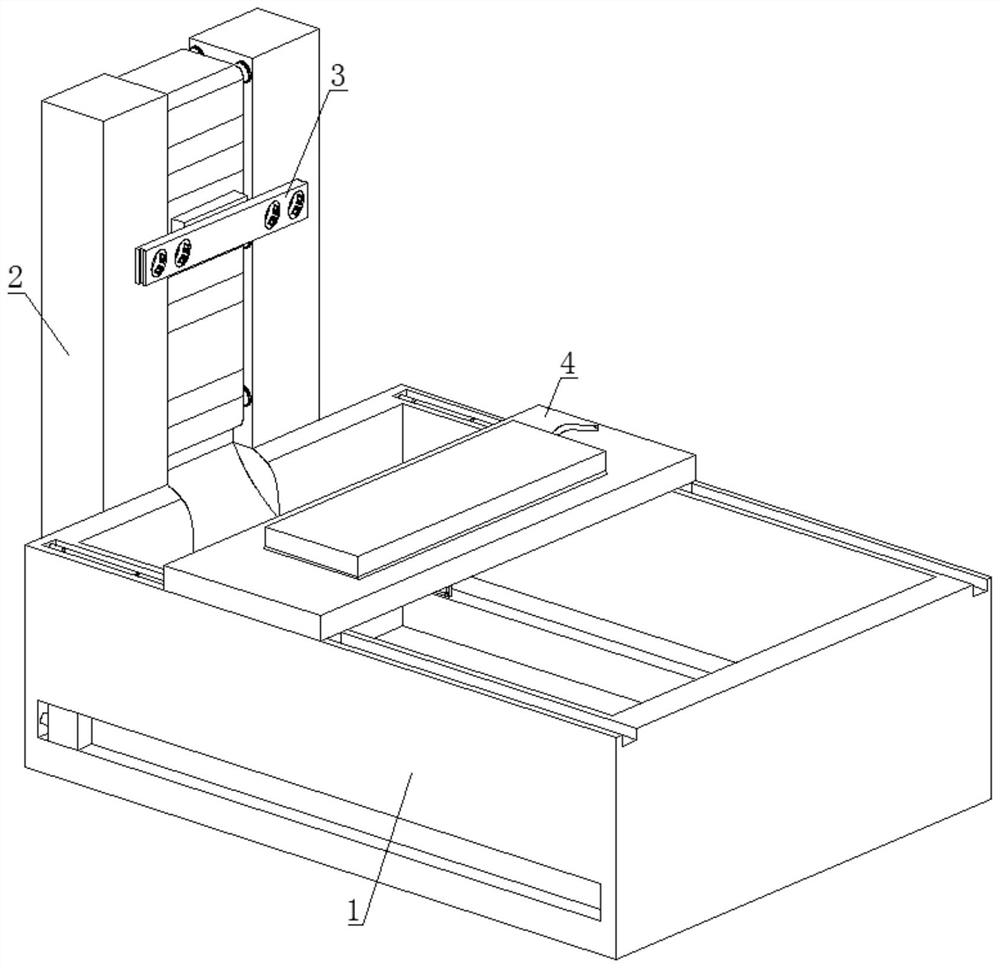

Hot galvanizing device and process for metal part production

A technology for producing heat and parts, applied in hot dip plating process, metal material coating process, coating and other directions, which can solve the problems of slow galvanizing efficiency and easy splashing of hot zinc solution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0041] In order to further and better explain the above-mentioned embodiments, the present invention also provides an embodiment, a process of a hot-dip galvanizing device for producing metal parts, comprising the following steps:

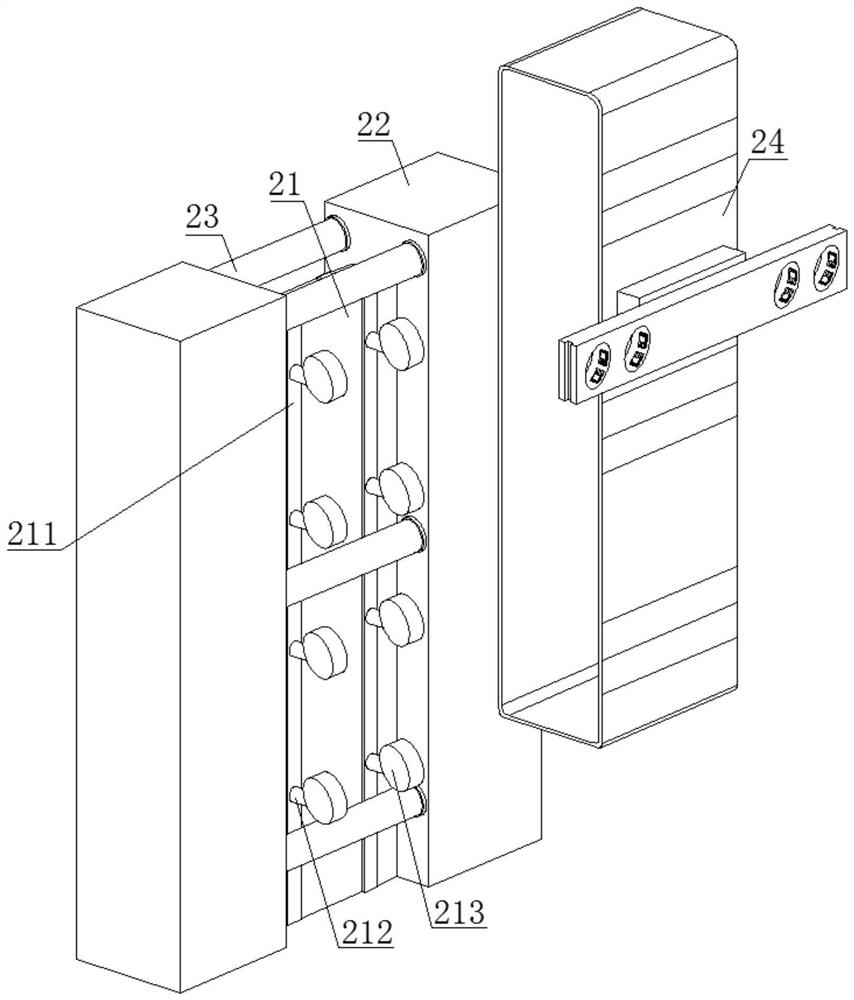

[0042] Step 1: place the metal parts inside the clamping hole 36, and then use the expansion and contraction of the telescopic micro-rod 371 to make the clamping thin plate 376 form a fixed clamping effect on the metal parts, and simultaneously connect the clamping mechanism 3 as a whole with the conveyor belt 24 In contact with each other, the clamping bottom block 31 is magnetically connected with the surrounding magnetic strip 211;

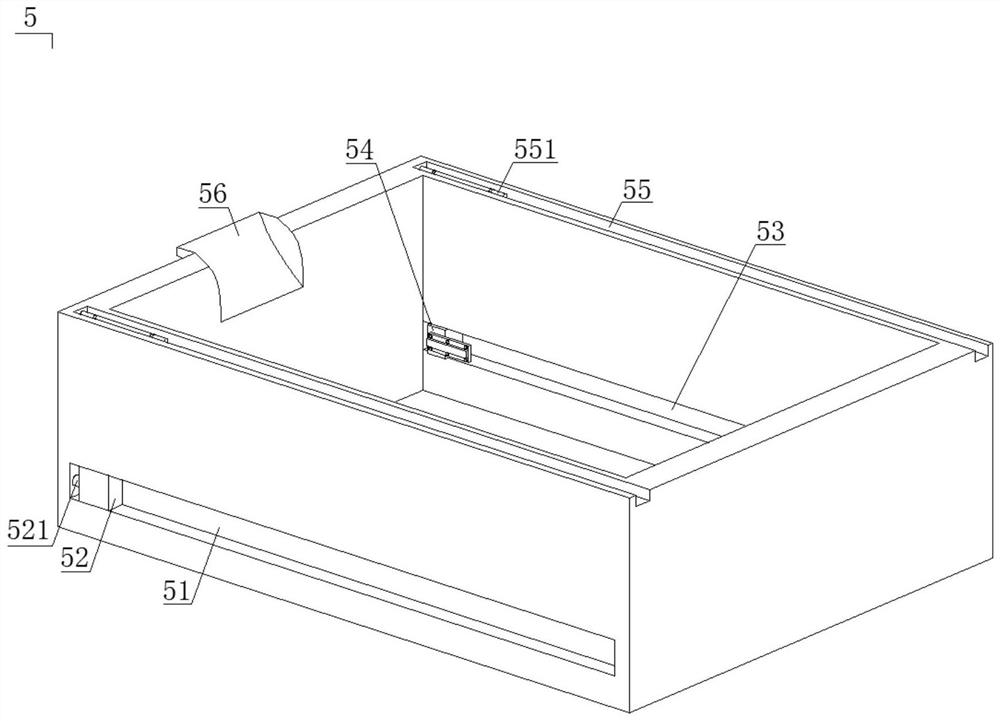

[0043] Step 2: Use the conveyor belt 24 to transport the clamping mechanism 3 as a whole to the arc groove 56, and recover the stretching tube 315 to make the stretching spring 33 jump out, and the clamping plate 34 will be inclined 90° due to gravity , and then through the mutual adsorption between the electromagne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com