Environment-friendly sealed hot galvanizing method

A sealed, hot-dip galvanizing technology, applied in hot-dip galvanizing process, coating, metal material coating process, etc. Zinc quality, the effect of increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

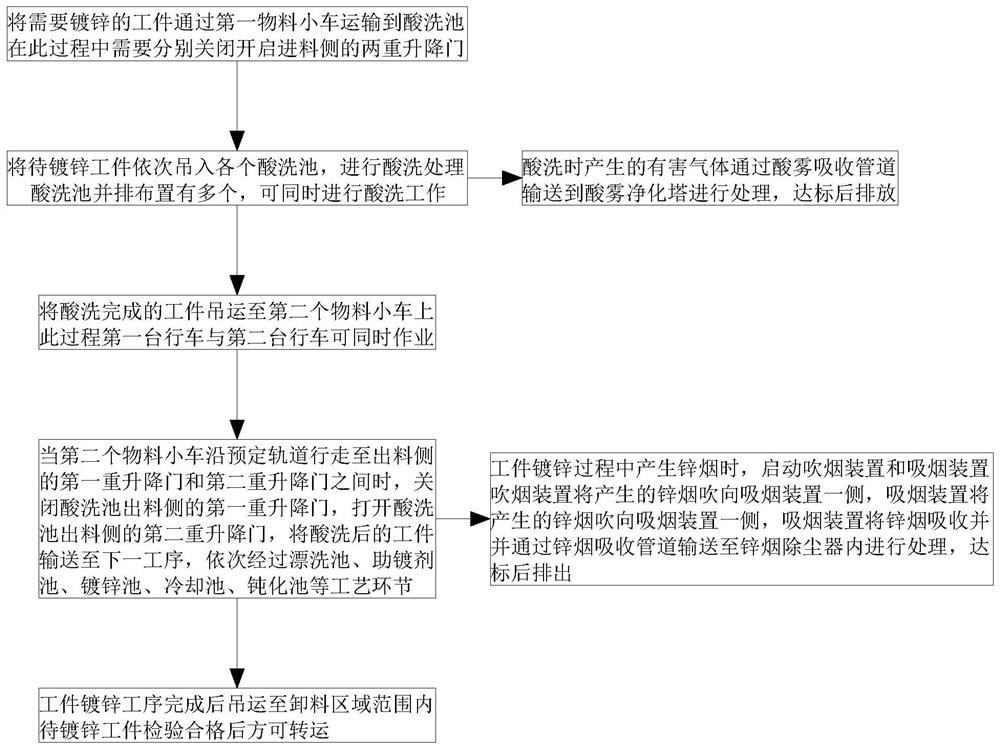

Embodiment 1

[0037] Process preparation: several pickling pools, rinsing pools, fluxing pools, galvanizing pools, cooling pools, passivation pools, unloading areas, and pickling pools are set up in sequence from left to right inside a closed steel structure. Both the material side and the discharge side are equipped with double doors; loading: put the workpiece to be galvanized on the material trolley, use the power switch to control the material trolley to walk along the predetermined track in a straight line, when the material trolley enters the closed steel structure, turn off the pickling The first lifting door on the feed side of the pool, at this time, start the switch to open the second lifting door, so that the material trolley can approach the pickling pool; pickling: when the workpiece to be galvanized is transported to the vicinity of the pickling pool, start The first crane lifts the workpieces to be galvanized into each pickling pool from right to left in turn, and starts pickl...

Embodiment 2

[0039] In embodiment one, add following operation:

[0040] In step 1, a transparent glass fiber reinforced plastic anti-corrosion plate is installed on the surface of the airtight steel structure, and a monitoring camera is installed inside the airtight steel structure to monitor the internal operation and ensure the quality of the galvanized workpiece.

[0041] Process preparation: several pickling pools, rinsing pools, fluxing pools, galvanizing pools, cooling pools, passivation pools, unloading areas, and pickling pools are set up in sequence from left to right inside a closed steel structure. Both the material side and the discharge side are equipped with double doors; loading: put the workpiece to be galvanized on the material trolley, use the power switch to control the material trolley to walk along the predetermined track in a straight line, when the material trolley enters the closed steel structure, turn off the pickling The first lifting door on the feed side of the ...

Embodiment 3

[0043] In embodiment two, add following operation:

[0044] In step 2, the first lift door on the feed side of the pickling tank is closed from top to bottom, the second lift door on the feed side of the pickling tank is opened from top to bottom, and the first lift door on the feed side of the pickling tank is opened from top to bottom. Both the heavy lift door and the second lift door are airtight doors, which help to ensure the tightness of the structure and reduce the leakage of acid gas.

[0045] Process preparation: several pickling pools, rinsing pools, fluxing pools, galvanizing pools, cooling pools, passivation pools, unloading areas, and pickling pools are set up in sequence from left to right inside a closed steel structure. Both the material side and the discharge side are equipped with double doors; loading: put the workpiece to be galvanized on the material trolley, use the power switch to control the material trolley to walk along the predetermined track in a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com