Metallic lacquer solid wood composite floor production process and floor thereof

A solid wood composite flooring and production process technology, which is applied to wood processing appliances, wooden veneer joints, manufacturing tools, etc., can solve the problems of weak adhesion between the metal paint layer and wood materials, poor rendering effect, and monotonous color. Achieve good visual effect and touch, clear texture, soft light and shadow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

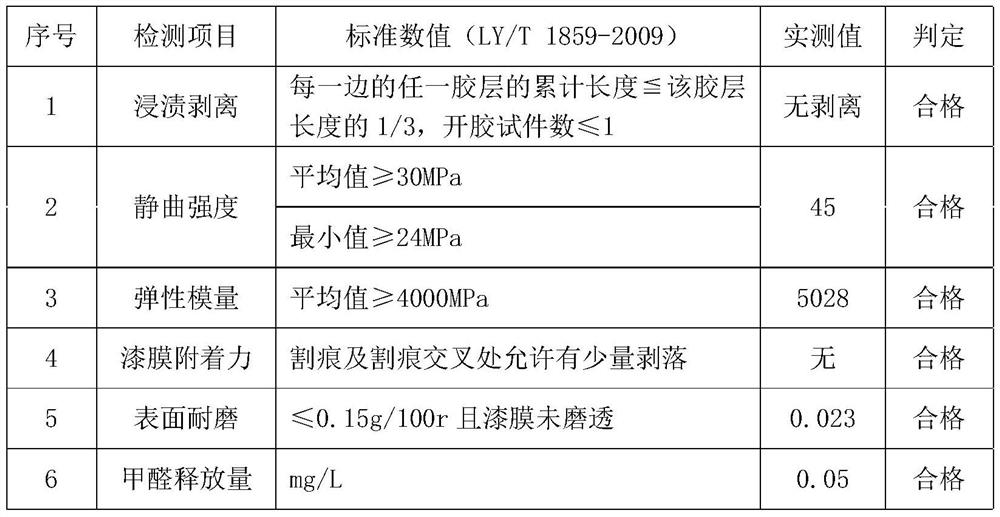

Embodiment 1

[0035] Take the product of 0.6mm oak veneer as an example. The veneer and the base material of corresponding specifications are veneered, hot-pressed, and then balanced for health. After 80 to 85 hours, the raw materials are cut to form a plain board. Carry out sanding to ensure that the surface of the board is flat and free of burrs. After sanding, carry out molding and groove treatment. After the tongue-and-groove treatment, wire drawing treatment is carried out, with a depth of 0.3-0.4mm; then whitening treatment; after that, the metal material is mixed with the primer and topcoat, and then evenly rolled on the surface; finally, the finished product is packaged and rolled off the assembly line.

Embodiment 2

[0037] Take the product of 0.6mm oak veneer as an example. The veneer and the base material of corresponding specifications are veneered, hot-pressed, and then balanced for health. After 80 to 85 hours, the raw materials are cut to form a plain board. Carry out sanding to ensure that the surface of the board is flat and free of burrs. After sanding, carry out molding and groove processing, and the size of further molding chamfering is 0.2 ~ 1mm. After the groove-and-groove treatment, wire-drawing treatment is carried out, the depth is 0.3-0.4mm; then whitening treatment is carried out, and the coating amount of white roller on the surface is about 30-40g / m 2 , After the roller coating is completed, it is dried to ensure that the surface is dry before sanding treatment; after that, the metal material is mixed with the primer and topcoat and evenly rolled on the surface; finally, the finished product is packaged and rolled off the assembly line.

Embodiment 3

[0039] Take the product of 0.6mm oak veneer as an example. The veneer and the base material of corresponding specifications are veneered, hot-pressed, and then balanced for health. After 80 to 85 hours, the raw materials are cut to form a plain board. Carry out sanding to ensure that the surface of the board is flat and free of burrs. After sanding, carry out molding and groove treatment. After the tongue-and-groove treatment, wire drawing treatment is carried out, with a depth of 0.3-0.4mm; then whitening treatment; after that, the metal material is mixed with the primer and top coat and then evenly rolled on the surface, and the mass ratio of the metal material to the water-based adhesive About 1:5, use a stirrer to fully stir evenly, disperse evenly, and not granulate, add 2% water to adjust, immediately use plastic film to seal the prepared barrel with the mixture to avoid prolonged use in contact with air. After the preparation is completed, use automatic roller coatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com