Modified polypropylene material for electric vehicle

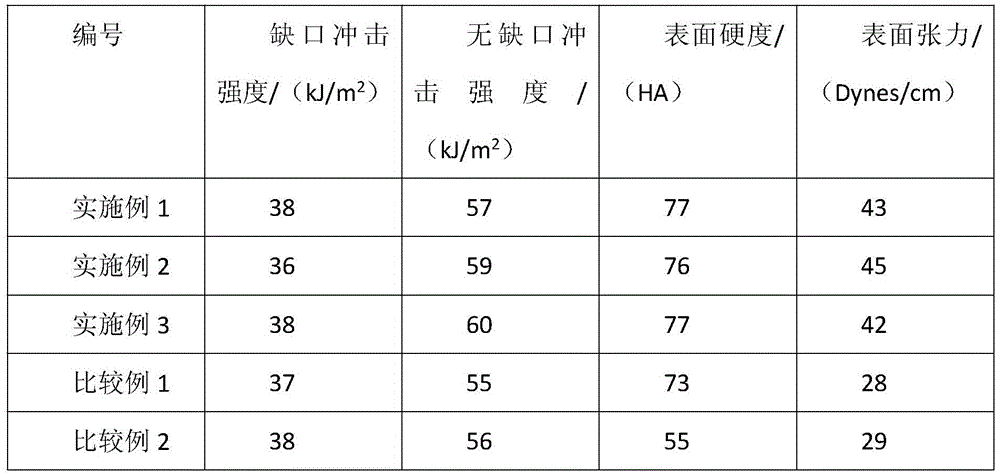

A polypropylene material and technology for electric vehicles, applied in the field of modified polypropylene materials for electric vehicles and their preparation, can solve the problems of poor aging resistance and degradation performance, reduce flexibility, affect performance, etc., and achieve excellent resistance to flying stone impact, The effect of improving surface tension and improving paint adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 100 parts of polypropylene, 15 parts of metallocene polyolefin elastomer, 3 parts of glass fiber, 5 parts of modified nano filler material, 9 parts of ethylene bis stearamide, 0.5 part of chlorinated polyethylene, and 0.2 part of antioxidant.

[0026] The antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester.

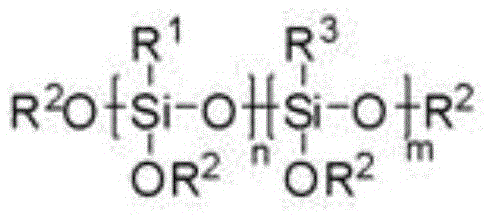

[0027] The modified nano-filling material is obtained by modifying the nano-filling material through alkyl alkoxysiloxane, wherein the nano-filling material is mixed with mica, silicon carbide, and boron nitride in a weight ratio of 5:1:1; The weight ratio of the nanofill material to the alkylalkoxysiloxane is 89:1.

[0028] Prepare the modified polypropylene material for electric vehicles according to the following steps:

[0029] ① Weigh polypropylene, metallocene polyolefin elastomer, glass fiber, modified nanofiller, ethylene bisstearamide, chlorinated polyethylene, antioxidant in proportion, and then mix in a high-spe...

Embodiment 2

[0033] 115 parts of polypropylene, 25 parts of metallocene polyolefin elastomer, 5 parts of glass fiber, 10 parts of modified nano-filler, 11 parts of ethylene bis-stearamide, 0.8 part of chlorinated polyethylene, and 0.4 part of antioxidant.

[0034] The antioxidant is β-(4-hydroxyphenyl-3,5-di-tert-butyl) n-octadecyl propionate.

[0035] The modified nano-filling material is obtained by modifying the nano-filling material through alkyl alkoxysiloxane, wherein the nano-filling material is mixed with mica, silicon carbide, and boron nitride in a weight ratio of 5:1:1; The weight ratio of the nanofill material to the alkylalkoxysiloxane is 89:1.

[0036] Process step is with embodiment 1.

Embodiment 3

[0038] 120 parts of polypropylene, 25 parts of metallocene polyolefin elastomer, 6 parts of glass fiber, 15 parts of modified nano filler material, 12 parts of ethylene bis stearamide, 0.9 part of chlorinated polyethylene, 0.6 part of antioxidant.

[0039] The antioxidant is selected from tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol esters.

[0040] The modified nano-filling material is obtained by modifying the nano-filling material through alkyl alkoxysiloxane, wherein the nano-filling material is mixed with mica, silicon carbide, and boron nitride in a weight ratio of 5:1:1; The weight ratio of the nanofill material to the alkylalkoxysiloxane is 89:1.

[0041] Process step is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com