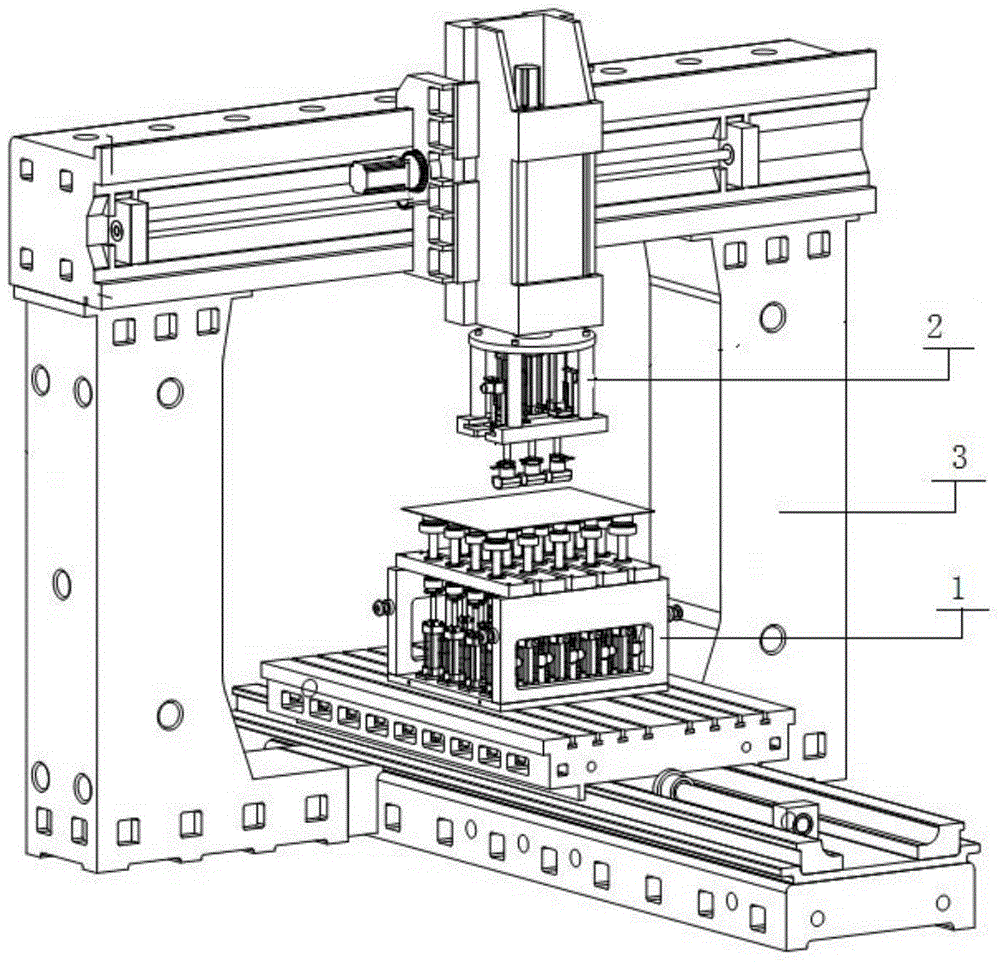

Flexible complex curved-plate machining equipment

A technology for complex curved surfaces and equipment, applied in metal processing equipment, forming tools, manufacturing tools, etc., to achieve the effects of high processing flexibility, easy operation, and good environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

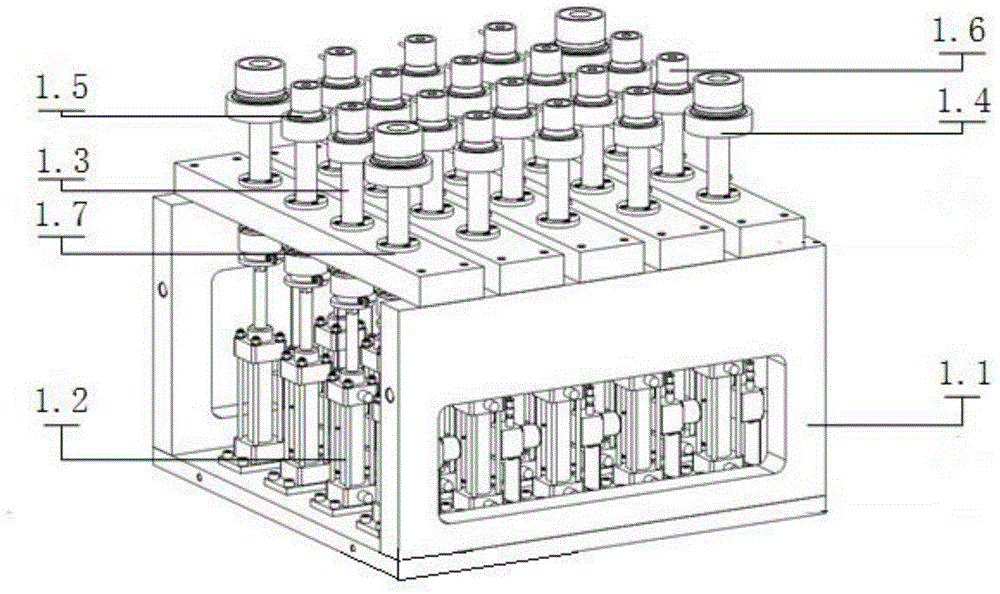

[0031] Embodiment 1: A support column that can be moved up and down, including an upper and lower base 1.1, characterized in that the hydraulic cylinder 1.2 is fixed on the lower layer of the base 1.1, the upper part of the hydraulic cylinder passes through the upper layer of the base 1.1 and is connected to the push rod 1.3, and the push rod 1.3 The universal ball joint seat 1.4 is fixed at the top, the universal ball joint 1.5 is placed on the universal ball joint seat 1.4, and the electromagnetic sucker 1.6 is fixed on the upper part of the universal ball joint 1.5.

Embodiment 2

[0032] Embodiment 2: A support column that can be moved up and down, including an upper and lower base 1.1, characterized in that: the hydraulic cylinder 1.2 is fixed on the lower layer of the base 1.1, the upper part of the hydraulic cylinder passes through the upper layer of the base 1.1 and is connected to the push rod 1.3, and the push rod 1.3 The universal ball joint seat 1.4 is fixed at the top, the universal ball joint 1.5 is placed on the universal ball joint seat 1.4, and the electromagnetic sucker 1.6 is fixed on the upper part of the universal ball joint 1.5.

[0033]The position where the upper part of the hydraulic cylinder 1.2 passes through the upper layer of the base 1.1 is provided with an oil-free bushing 1.7.

Embodiment 3

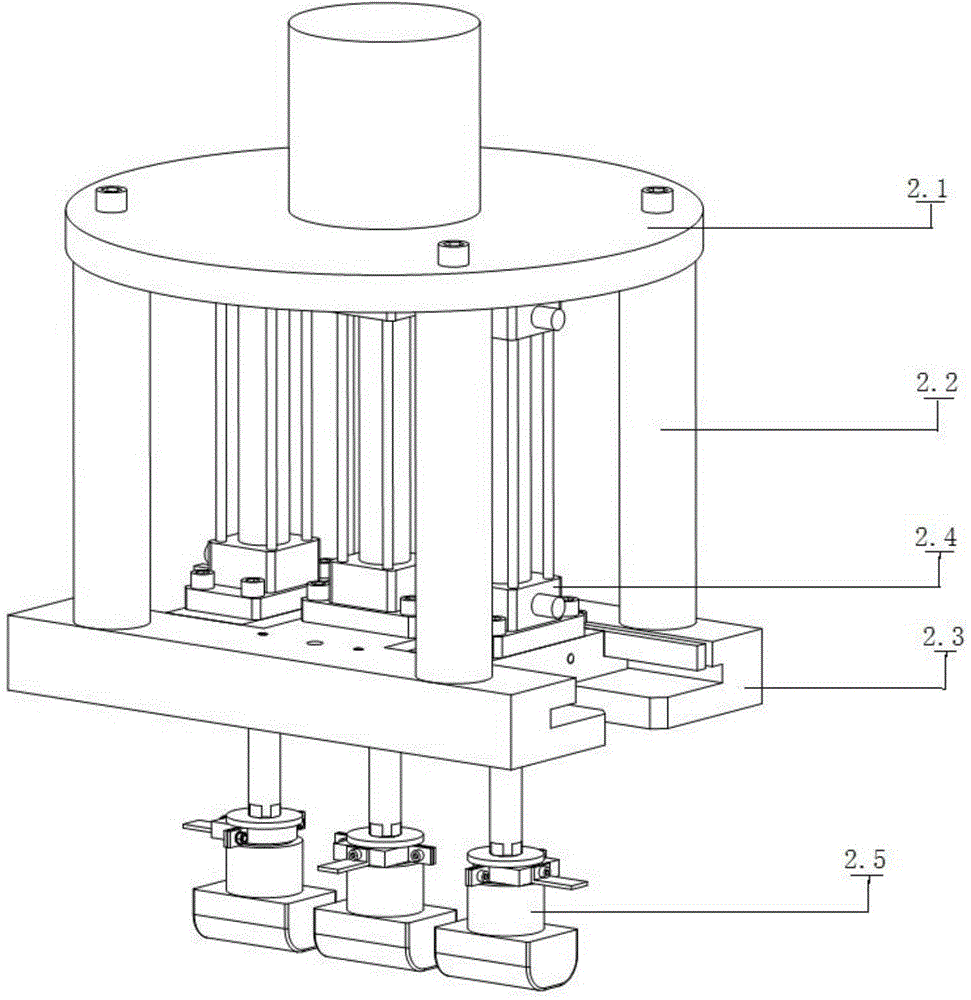

[0034] Embodiment 3: A bent plate indenter, including a fixed frame 2.1, characterized in that: the side column 2.2 is fixed under the fixed frame 2.1, the parallel rail 2.3 is fixed at the lower end of the side column 2.2, the moving block 2.4 is placed on the parallel rail 2.3, and the moving block 2.4 The lower part fixes the stamping tool head 2.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com