Method for inducing nodular cast iron to synthesize graphene in situ

A ductile iron, in-situ self-generating technology, applied in the field of material modification, can solve the problems of complex process and low bonding strength, and achieve the effects of controllable process, improved thermal conductivity and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

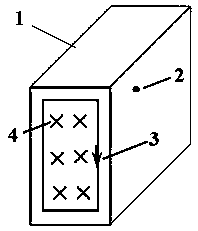

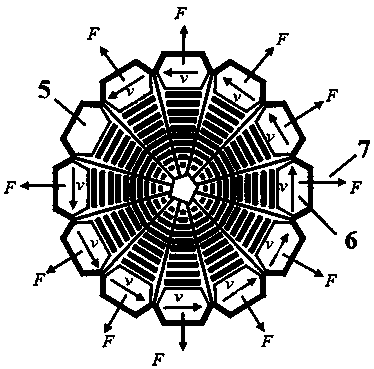

[0032] Such as figure 1 , 2 As shown, the base material of the nodular cast iron component is cuboid nodular cast iron with the grade QT500, first clean the QT500 nodular cast iron cuboid base material 1, and clean and dry the surface. In view of the fact that the ductile iron itself contains freely movable electrons, the spherical graphite 2 in the ductile iron cuboid substrate 1 also contains freely movable electrons in its carbon atom sheet 5, so applying a power source makes the freely movable electrons become directionally moving. Carriers, forming a clockwise current 3 along the circumference of the substrate surface, the current size is 3A, such as figure 1 shown.

[0033] Under the condition that the clockwise current direction remains unchanged, the magnitude of the current is rapidly reduced to 1A, and the rate of change of the rapid reduction of the current is 100A / s. According to Lenz's law, the change of the magnitude of the current will stimulate the cross-sect...

Embodiment 2

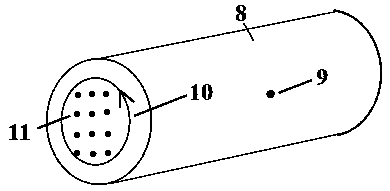

[0036] Such as image 3 , 4As shown, the base material of the ductile iron component is cylindrical ductile iron with the grade QT600. Clean the QT600 ductile iron cylinder substrate 8, and clean and dry the surface. In view of the fact that nodular cast iron itself contains freely movable electrons, the carbon atom sheets 12 of spherical graphite 9 in the matrix also contain freely movable electrons, so the application of power makes the freely movable electrons become directional carriers, forming The current 10 counterclockwise along the circumference of the substrate, the magnitude of the current is 5A, such as image 3 shown.

[0037] Under the condition that the counterclockwise current direction remains unchanged, the magnitude of the current is rapidly reduced to 1A, and the rate of change is 200A / s. According to Lenz’s law, the change of the magnitude of the current will excite the vertical force that runs through the cross-section of the ductile iron cylinder subs...

Embodiment 3

[0039] Such as Figure 5 , 6 , 7, the base material of the nodular cast iron component is the conical nodular cast iron with the grade QT400. Clean the QT400 ductile iron cone substrate 15, and clean and dry the surface. In view of the fact that nodular cast iron itself contains freely movable electrons, the carbon atom sheets 20 of spherical graphite 16 in the matrix also contain freely movable electrons, so the application of power makes the freely movable electrons become directional carriers, forming The current 17 in the counterclockwise direction along the circumference of the substrate, the magnitude of the current 17 is 5A, such as Figure 5 shown.

[0040] Under the condition that the magnitude of the current is constant, change the direction of the current rapidly, so that the direction of the current 17 becomes clockwise, and then becomes the clockwise current 18. The time for the change of the current direction is 0.05s. According to Lenz’s law, the direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com