3D printing manufacturing method for surface micro-texture of friction pair

A production method and 3D printing technology, applied in the directions of additive manufacturing, process efficiency improvement, additive processing, etc., can solve the problems of insignificant anti-friction effect and high production cost, and achieve the effect of wide application range and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

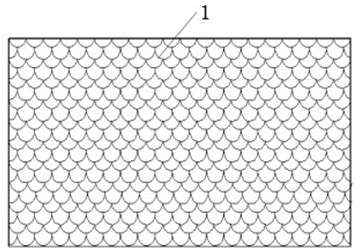

Embodiment 1

[0028] The 3D printing method of implementing the micro-texture on the surface of the friction pair is applied to the vane of the vane pump or motor. The shape of the micro-texture is fish scale, see the attached figure 1 , 1 is a blade with fish scale microtexture, the surface of the blade is covered with fish scale microtexture, the depth is 0.04mm, the width (laser beam spot diameter) is 0.2mm, and the interval between two textures is 1.5mm. Use a CNC grinder to treat the surface of the friction pair, clean the oxide and rust on the surface of the raw material plate of the blade, and make the surface of the raw material plate of the blade smooth and bright; use the computer 3D CAD software to make the scale micro-texture required on the surface of the raw material plate of the blade. Draw to obtain the three-dimensional model of the fish scale micro-texture, and then use a series of small triangle planes to approximate the irregular surface on the model, so as to obtain the ...

Embodiment 2

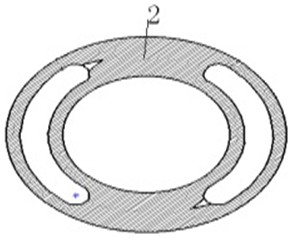

[0030] The 3D printing method of implementing the microtexture on the surface of the friction pair is applied to the valve plate 2 with a cylindrical microtexture, the shape of the microtexture is cylindrical, see the attached figure 2 , the contact surface between the valve plate and the cylinder body is covered with cylindrical micro-textures, the depth is 0.02mm, and the area is 0.1mm 2 , occupying an area ratio of 15%. The cylindrical micro-texture on the surface of the valve plate stores a certain amount of oil to increase the thickness of the oil film and increase the supporting force of the oil film, thereby reducing friction and wear. The manufacturing method of the cylindrical micro-texture on the surface of the required friction pair Same as Example 1.

Embodiment 3

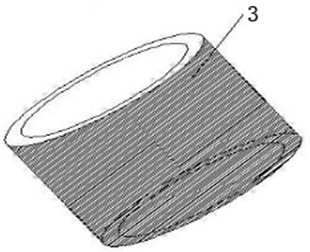

[0032] The 3D printing method of implementing the micro-texture on the surface of the friction pair is applied to the contact surface between the inner and outer ring of the roller (ball) bearing and the roller (ball). The shape of the micro-texture is rhombus, see the attached image 3 And attached Figure 4 , 3 is the inner ring of roller bearing with rhombic micro-texture, 4 is the outer ring of roller bearing with rhombic micro-texture. structure, the area ratio is 15%, and the area of micro-texture is 0.2mm2 , the depth is 0.02mm, and the manufacturing method of the rhombic micro-texture on the surface of the desired friction pair is the same as that in Example 1.

[0033] In summary, this method provides a 3D printing manufacturing method for the surface micro-texture of the friction pair, which overcomes some deficiencies and limitations of the friction pair in the background technology, improves the lubrication performance of the friction pair, and improves the frict...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com