Preparation method of graphene composite film with conducting circuit on surface

A graphene composite and graphene film technology, applied to the conductive layer on the insulating carrier, etc., can solve the problems that the graphene film is damaged, easy to fall off, unsuitable for flexible electronic and electrical applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a kind of preparation method of the graphene composite film with conductive circuit, comprises the following steps:

[0035] 1) forming a conductive line on the surface of the first substrate to obtain a substrate material;

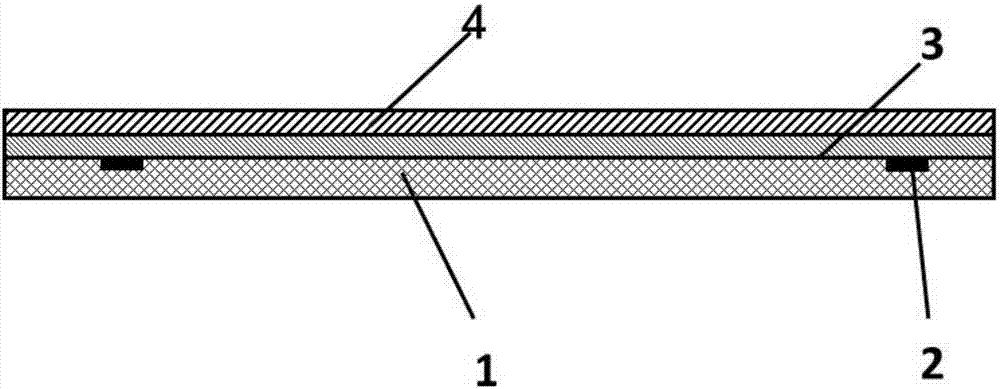

[0036] 2) Obtaining the above-mentioned steps on the surface with conductive lines of the substrate material, compounding one or more layers of graphene film, and then combining the second substrate on the surface of the graphene film to obtain an intermediate product;

[0037] 3) Removing the first substrate of the intermediate product by chemical etching to obtain a graphene composite film with conductive lines.

[0038] In the present invention, firstly, conductive lines are formed on the surface of the first substrate to obtain the substrate material.

[0039] In the present invention, the material of the first substrate is not particularly limited, and the material of the substrate well-known to those skilled in the art...

Embodiment 1

[0075] a. Nickel electroplating is used to form the circuit shape on the copper foil.

[0076] Combine copper foil with plastic mask. The required circuit shape is hollowed out on the plastic mask. Put the copper foil / plastic mask into the electroplating solution, pass through the current, and form a nickel circuit of the desired shape on the copper foil. The numerical value of the passing current is 0.1-10A.

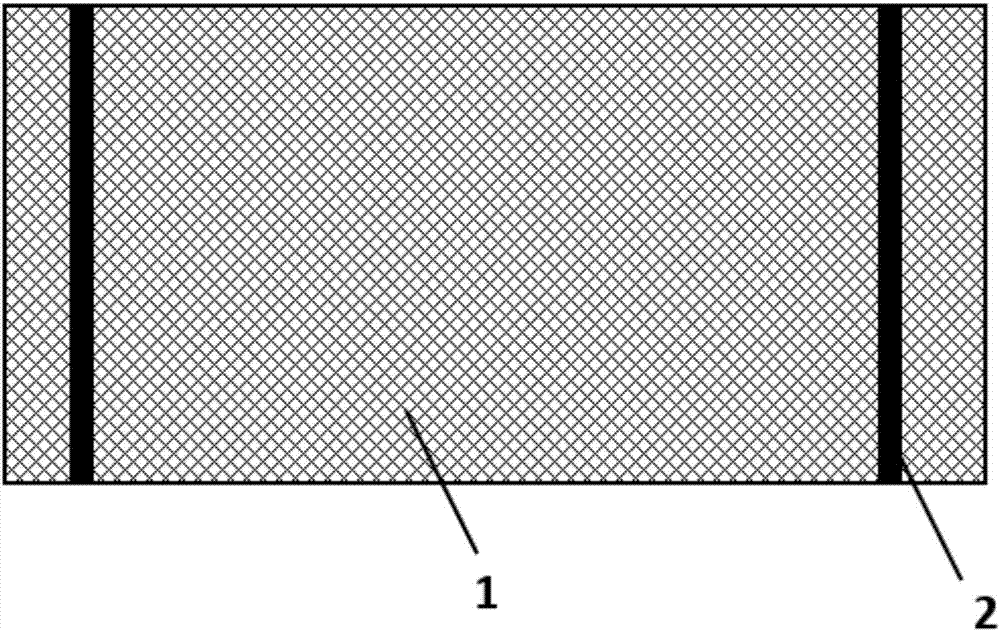

[0077] see figure 1 , figure 1 It is a schematic top view structure diagram of the product formed in step a of Example 1 of the present invention. Wherein, 1 is the first substrate, and 2 is a highly conductive pattern (conductive circuit).

[0078] b. A graphene film is grown on the surface of the copper foil by chemical vapor deposition.

[0079] Put the copper foil into the chemical vapor deposition equipment, evacuate and heat up to the growth temperature of 1000±50°C, and inject methane to obtain the graphene film.

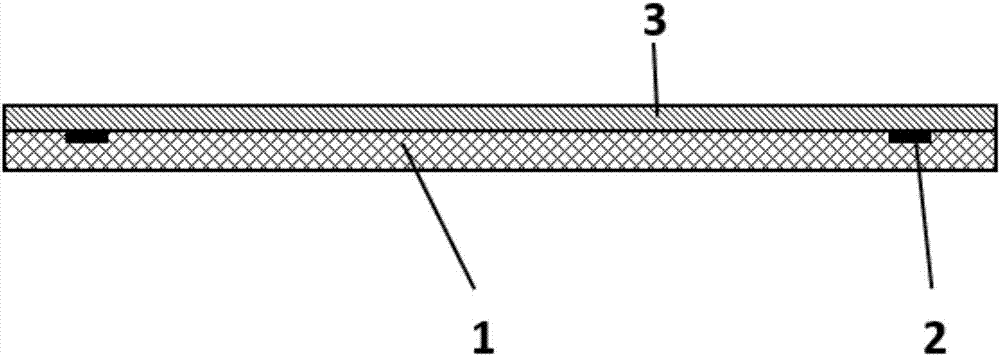

[0080] see figure 2 , figure 2 It is ...

Embodiment 2

[0089] a. Nickel electroplating is used to form the circuit shape on the copper foil.

[0090] Combine copper foil and glass mask. The desired circuit shape is hollowed out on the glass mask. Put the copper foil / glass mask into the electroplating solution, pass through the current, and form a nickel circuit of the desired shape on the copper foil. The numerical value of the passing current was 5A.

[0091] b. A graphene film is grown on the surface of the copper foil by chemical vapor deposition.

[0092] Put the copper foil into the chemical vapor deposition equipment, evacuate and heat up to the growth temperature of 1000±50°C, and feed ethylene to obtain the graphene film.

[0093] c. Then bond the graphene film surface of the copper foil to the PEN transparent substrate with hot melt adhesive.

[0094] d. Then put the bonded transparent substrate, graphene and copper foil into the etching solution. The etching solution is composed of a mixed solution of copper sulfate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com